Modern tram trough type steel rail fastener

A technology for grooved steel rails and trams, which is applied in the direction of tracks, fixed rails, track superstructures, etc., can solve the problems of unfavorable tram track system development, inability to directly use track components, and inconvenient track maintenance and repair, etc., to achieve Good insulation performance, few parts and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

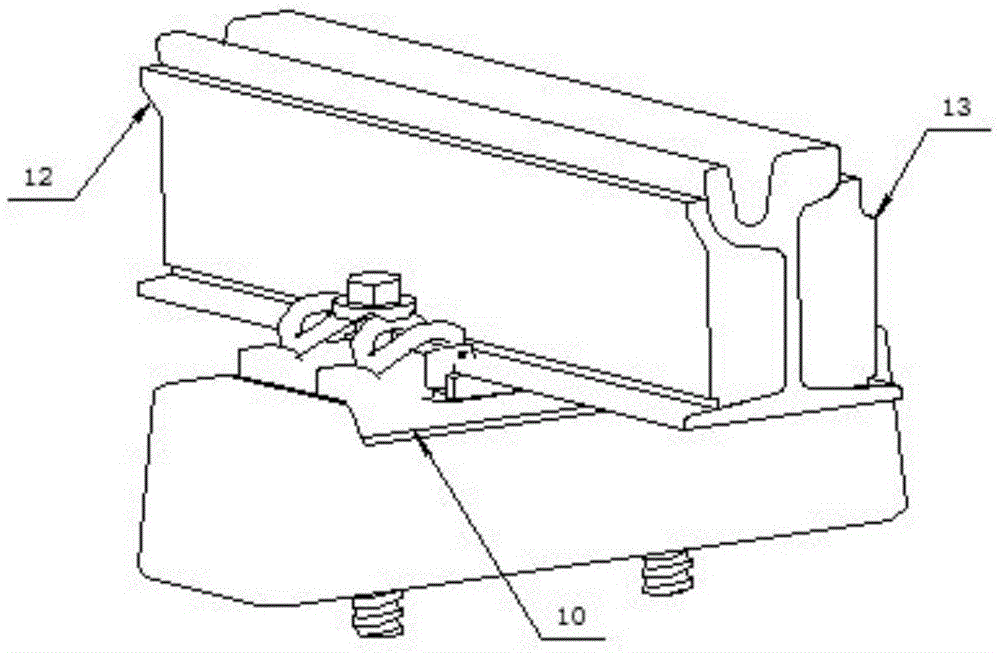

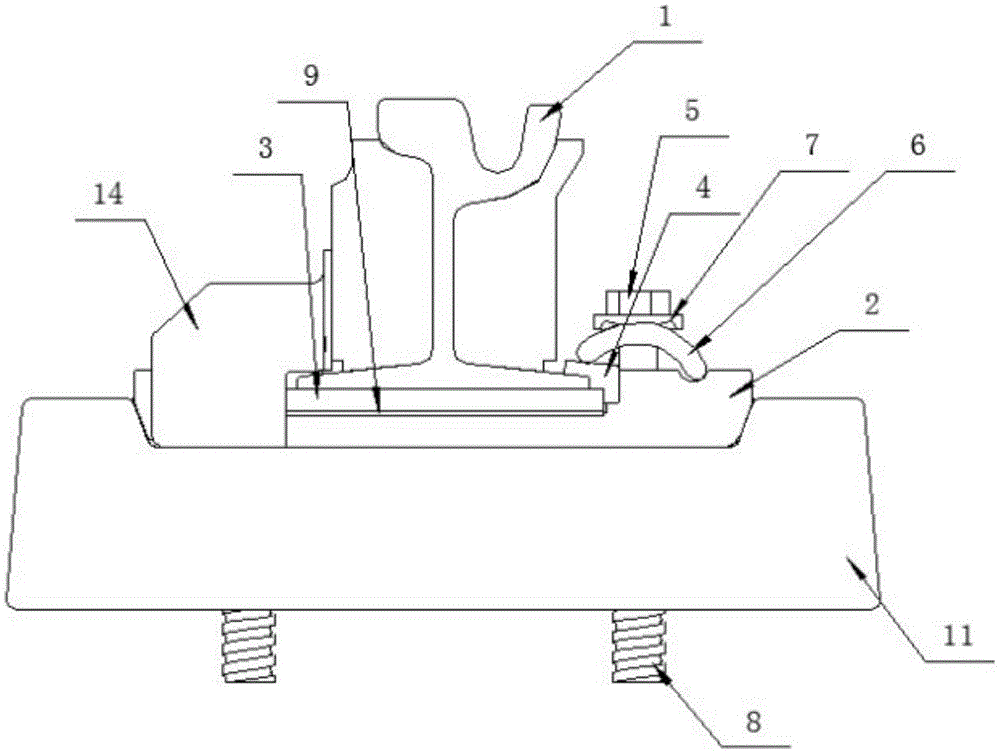

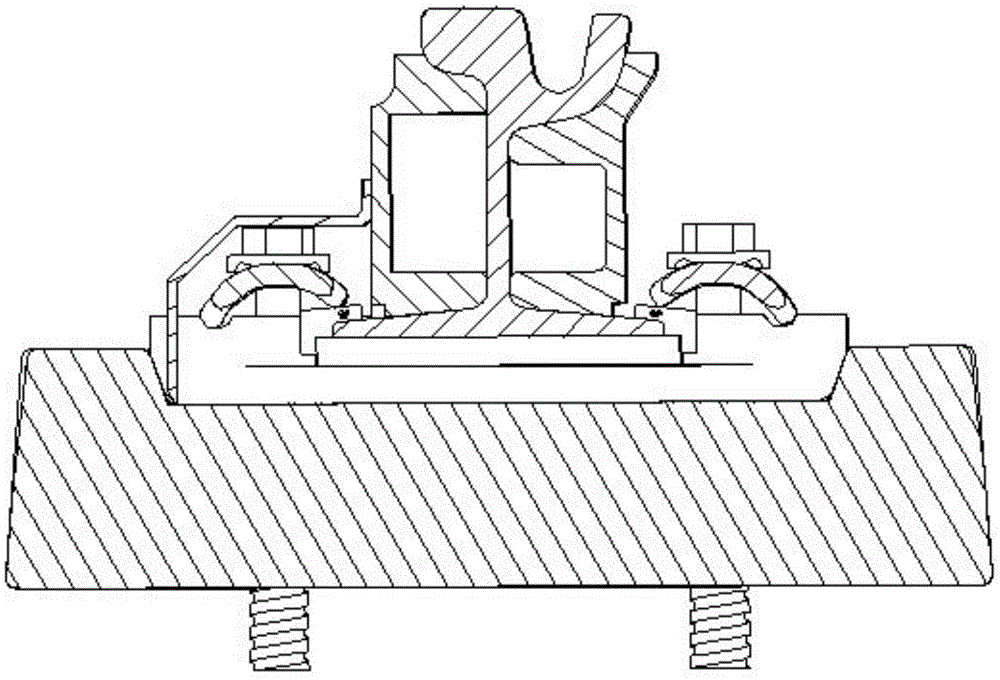

[0024] The present invention will be further described below in conjunction with accompanying drawing:

[0025] like figure 1 , figure 2 and image 3 As shown: the present invention includes a rail 1, a base plate 2, a backing plate 3 under the rail, a gauge block 4, a spiral spike 5, an elastic strip 6, an anti-loosening washer 7, a pre-embedded casing 8, an under-rail height-adjusting backing plate 9, The under-slab height adjustment backing plate 10 and the sleeper 11, the embedded casing 8 is arranged under the sleeper 11, the base plate 2 is located on the sleeper 11, the under-slab height adjustment backing plate 10 is located on the base plate 2, and the under-rail height adjustment backing plate 9 is located on the under-slab height adjustment pad On the plate 10, the steel rail 1 is located on the height-adjusting backing plate 9 under the rail, and there are two gauge blocks 4, spring bars 6, anti-loosening washers 7, and spiral spikes 5, and the gauge blocks 4 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com