Desilting pump

A technology for dredging pumps and pump casings, which is applied in the field of engineering vehicles, can solve problems such as inability to effectively crack, poor dredging effect of dredging pumps, and affecting normal operation of pump bodies, so as to improve service life and improve dredging effect, to ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

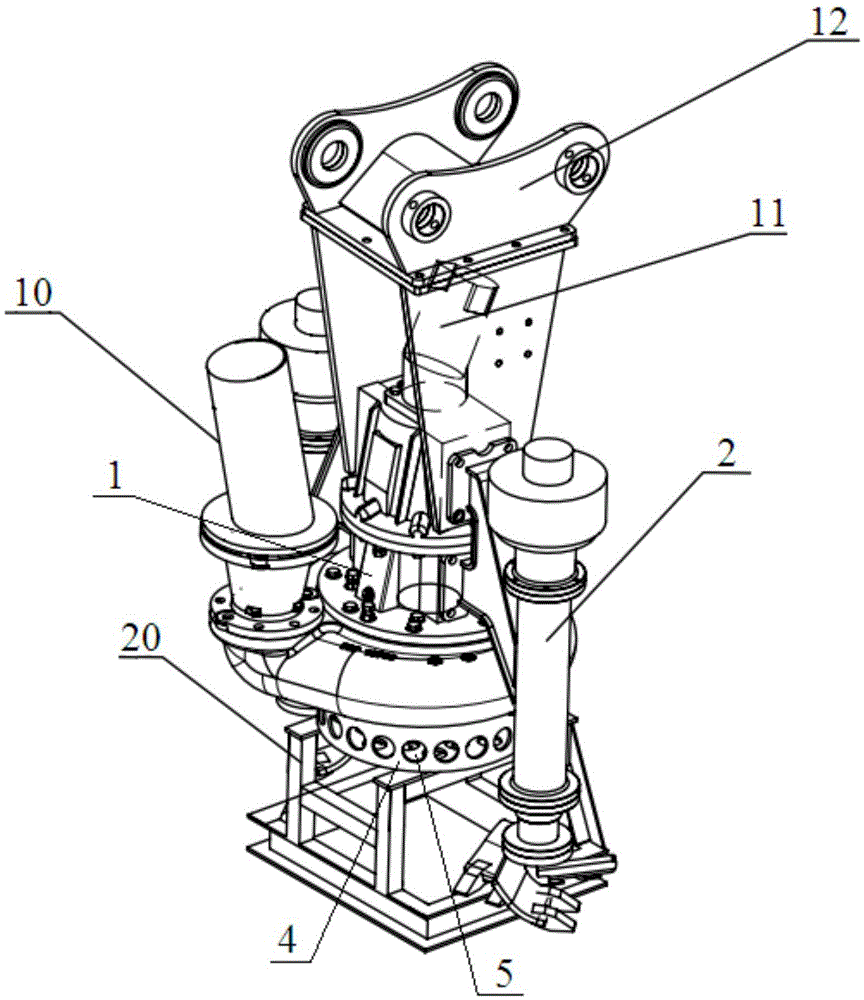

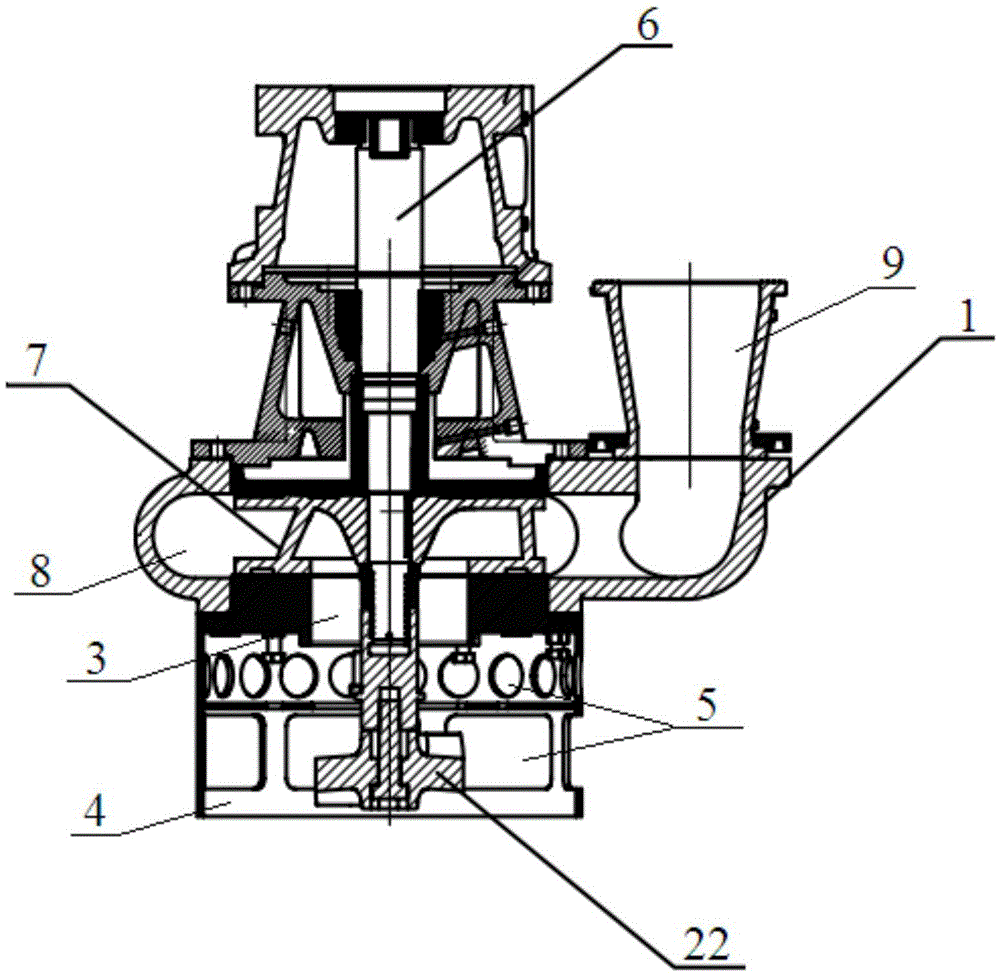

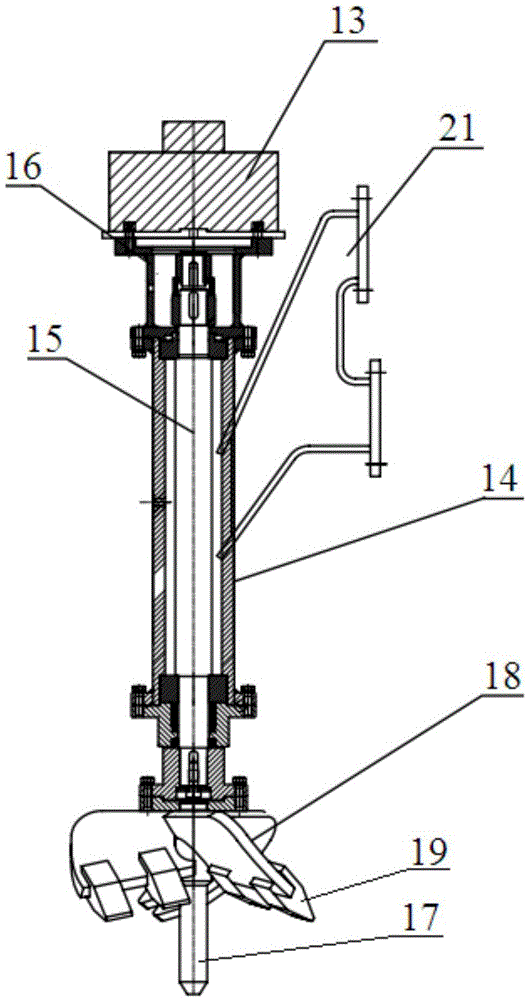

[0017] Referring to the accompanying drawings, a dredging pump includes a dredging mechanism and a left and right stirring mechanism 2. The dredging mechanism includes a pump casing. The bottom end of the pump casing 1 is provided with a silt inlet 3 and is fixedly connected with a silt inlet cylinder. 4. A plurality of silt inlet holes 5 of different sizes and the same size are provided on the surrounding side walls of the silt inlet cylinder 4. A main shaft 6 is installed in rotation in the pump casing 1, and an impeller is installed on the main shaft 6 above the silt inlet 3. 7. The lower end of the main shaft 6 passes through the inlet and outlet silt 3 and extends into the silt inlet cylinder 4, and is equipped with an agitator 22. The inside of the pump casing 1 is provided with an annular channel 8 around the impeller 7, and one side of the pump casing 1 is provided with There is a silt outlet 9 connected with the annular channel 8 and connected with a silt outlet pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com