Inverted arch beam string structure roof of large-span steel structure and construction method thereof

A steel structure, large-span technology, used in roofs, building components, building structures, etc., can solve problems such as large angles between cables and struts, difficulty in ensuring machining accuracy, and inability to meet construction requirements, ensuring stability. , The tensioning process is convenient and fast, and the installation is orderly and fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

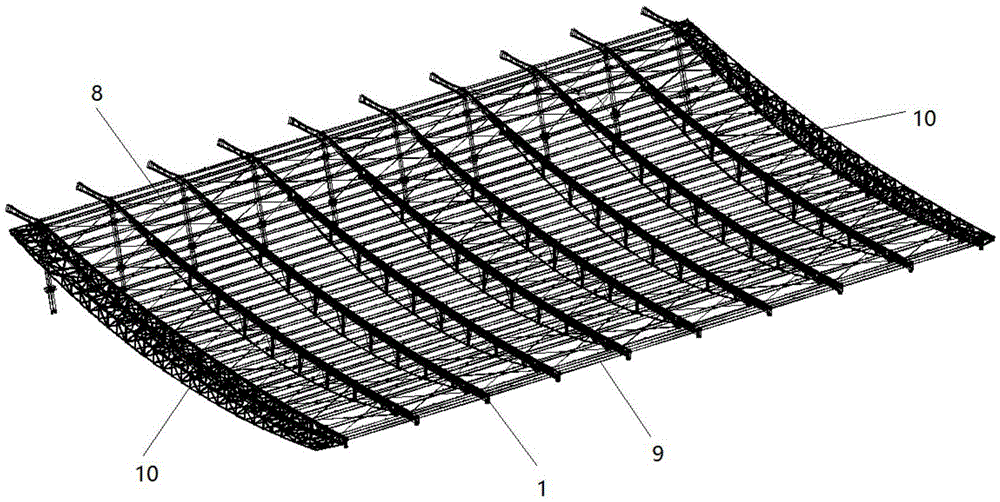

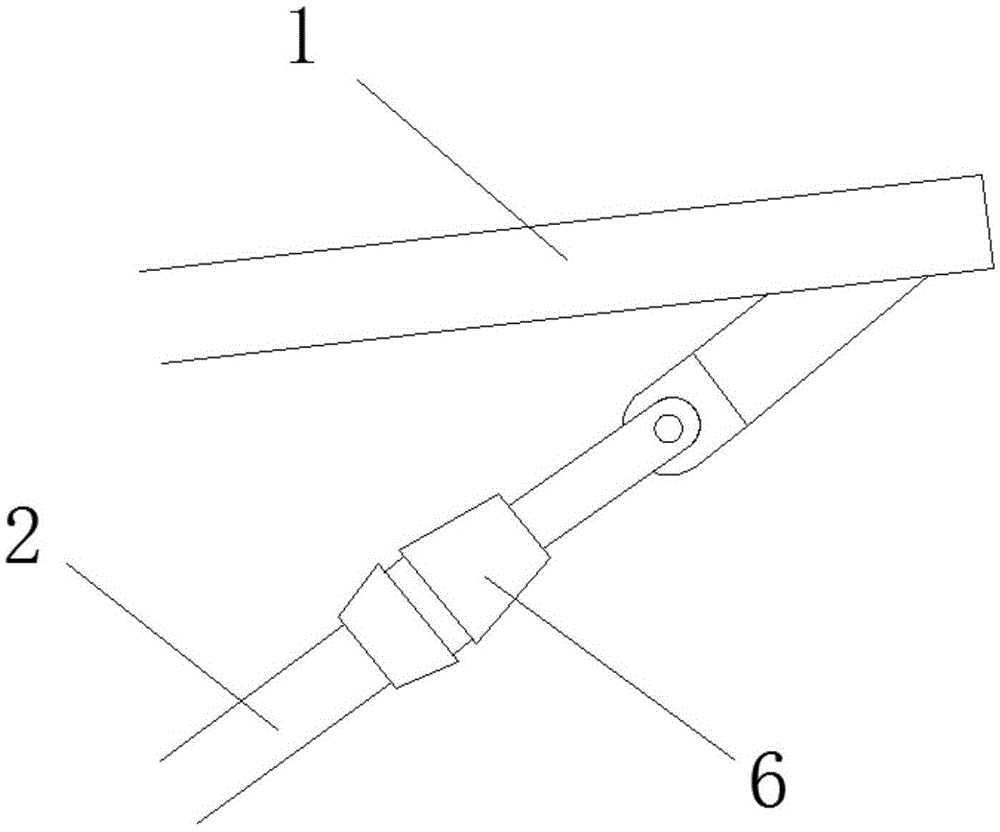

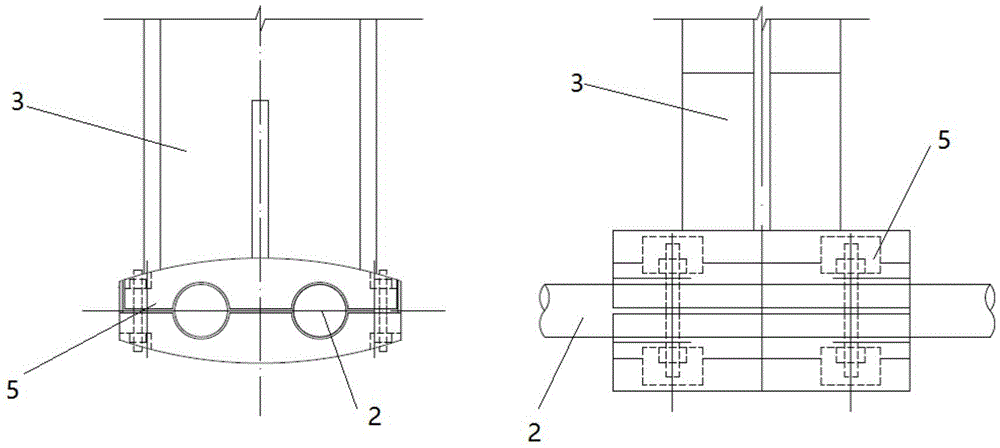

[0033] like Figure 1~6 The shown large-span steel structure anti-arch string beam roof includes a group of unit beams arranged in parallel and purlins 9 vertically distributed between adjacent unit beams; the two ends of the group of unit beams are provided with pipe trusses 10 ; The unit beam includes a string beam 1 and a cable 2 located at its lower part, wherein the string beam 1 is welded in sections by a box-shaped steel beam, and the cable 2 is processed by a high-vanadium-coated cable with a diameter of 95 mm to 100 mm; A plurality of struts 3 are arranged between the string string 1 and the stay cable 2; as figure 2 , image 3 The upper end of the shown strut 3 is fixedly connected to the string beam 1 through the pin shaft, and the lower end is fixedly connected to the cable 2 through the steel casting rigging 5, wherein two cable 2 are provided, which pass through the steel casting rigging 5 respectively. The two through holes are tightened by steel casting rigg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com