Light composite insulating brick masonry technology

A technology of composite thermal insulation and thermal insulation bricks, which is applied in the direction of thermal insulation and building components, etc., can solve the problems of large gaps between lightweight thermal insulation bricks, large volume of anti-falling installation components, and reduced thermal insulation effect of lightweight thermal insulation bricks, so as to save installation engineering, The effect of simple structure and strong load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

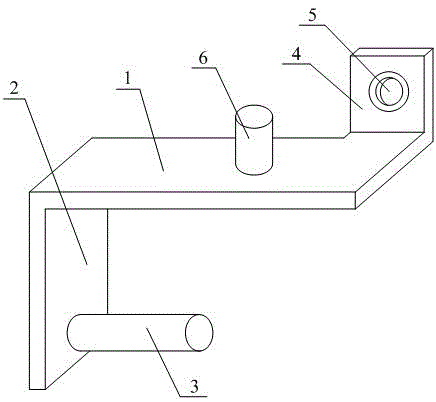

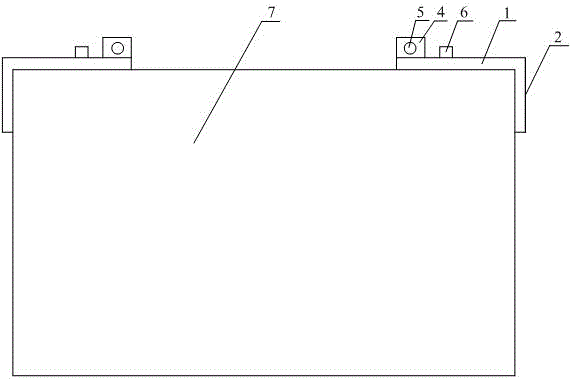

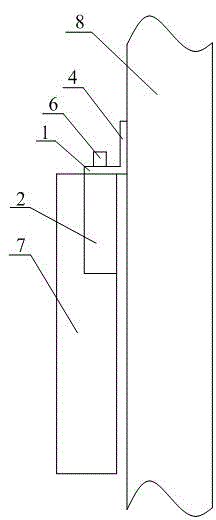

[0026] Such as Figure 1~4 As shown, the present invention is mainly composed of a fixed plate, the fixed plate is a thin metal plate, and the thickness of the thin metal plate is not more than 1mm, and a stainless steel plate or an aluminum alloy plate can be preferably used. The fixed plate is bent to form a horizontal plate 1 and a vertical plate 2 connected end to end, and the horizontal plate 1 and the vertical plate 2 are perpendicular to each other.

[0027] In order to facilitate the connection of the fixed plate to the light heat insulating brick 7, a fixed bolt 3 is also provided on the fixed plate. The fixed bolt 3 is cylindrical as a whole, and its cross section is circular or rectangular. In this embodiment Preferably round, such as figure 1 shown. The fixed bolt 3 is connected to the vertical plate 2, the fixed bolt 3 is perpendicular to the vertical plate 2, and is located on the same side of the vertical plate 2 as the horizontal plate 1. In order to facilit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com