Explosion-proof curtain wall plate

A curtain wall panel and back panel technology, applied to walls, building components, buildings, etc., can solve problems such as hidden safety hazards, increased construction difficulty, uneconomical installation and use, etc., and achieve the effects of stable transmission, safe use, and prevention of bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

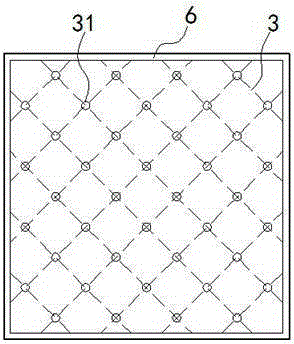

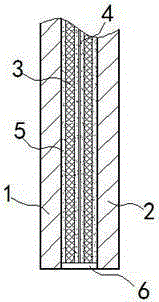

[0014] exist figure 1 , figure 2 In the shown embodiment, this explosion-proof curtain wall panel includes an outer layer plate 1 and a back plate 2; a wire mesh 3 is clamped between the outer layer plate 1 and the back plate 2, and a wire mesh 3 is glued on the wire mesh 3. Hard isolation beads 31 are attached, and fluorescent powder is coated on the surface of each isolation bead 31; a separation film 4 is also sandwiched between the outer layer plate 1 and the back plate 2, and the two screens 3 are symmetrical are distributed on both sides of the separation film 4; the periphery of the outer layer plate 1 and the back plate 2 are adhered by colloid to form a liquid-sealed cavity 5, and the cavity 5 is filled with heat insulating liquid, The thermal insulation liquid includes purified water; the explosion-proof curtain wall panel also includes an elastic ring 6 communicating with the cavity 5, and the elastic ring 6 is clamped between the back plate 2 and the outer layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com