Quick repair method for continuous collapse of RC framework structure

A repair method and frame structure technology, applied in building maintenance, building structure, construction, etc., can solve problems such as economic loss, reconstruction cycle and long shutdown period, and achieve significant social benefits, short repair cycle, and improved economy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0027] Specific embodiment one: a kind of rapid repair method based on the continuous collapse of RC frame structure of this embodiment is specifically implemented according to the following steps:

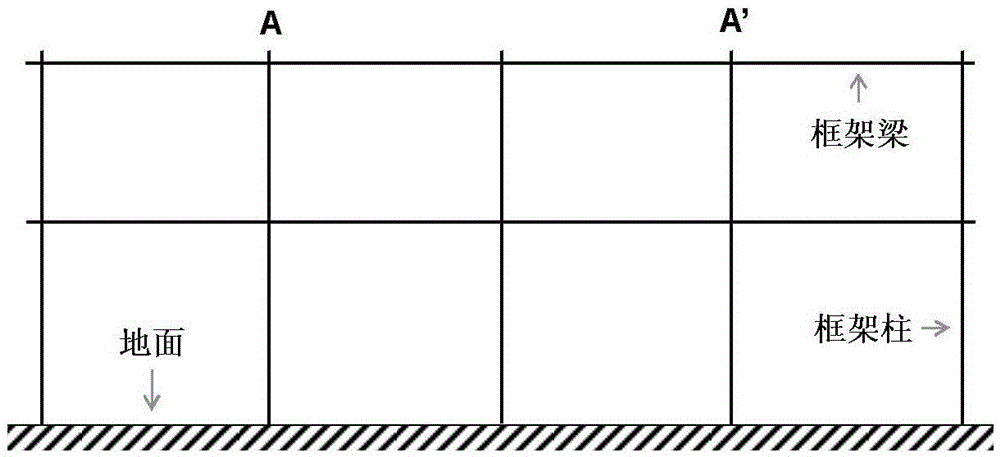

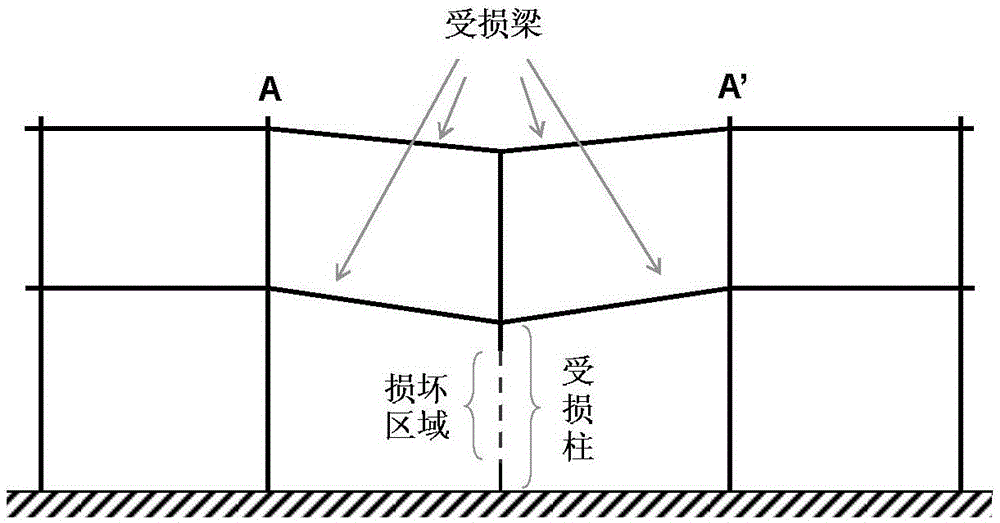

[0028] The continuous collapse of the RC frame structure refers to the downward deformation of the frame beam in the damaged column and the upper layer of the structure shown in Figure 1(a) after a certain column is damaged, as shown in Figure 1(b) ) shown in ; the damage location is the damaged column itself and the end area of the beam in the AA' axis;

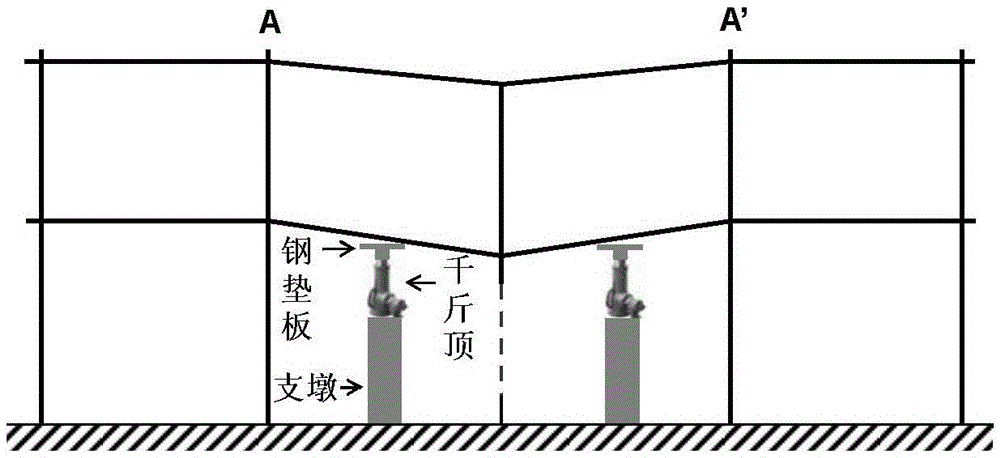

[0029] The equipment and materials required for the rapid repair method for the continuous collapse of the RC frame structure specifically include: buttresses, jacks, steel backing plates, steel bars, and grouting materials; wherein, the steel bars are used for longitudinal steel bars or for stirrups;

[0030] The steel backing plate is a square steel plate with the same size as the width of the damaged beam; the longitudinal ...

specific Embodiment approach 2

[0047] Embodiment 2: This embodiment differs from Embodiment 1 in that: the length of the steel pipe described in Step 1 is 4 cm. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0048] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step 7, one end of the reinforcing bar of the planting bar is implanted into the minimum length l of the node at the beam-column fracture. min Press formula l min =max{0.3l s 10d100mm} calculation, where d is the nominal diameter of the implanted reinforcement (unit: mm), f y It is the design value of the tensile strength of the implanted steel bar (unit: N / mm 2 ), f bd is the design value of bond shear strength of planting glue (unit: N / mm 2 ); other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com