Wellhead combination testing device and method for water injection well

A combined testing and water injection well technology, applied in wellbore/well components, measurement, earthmoving, etc., can solve problems such as failure to monitor pressure data at the wellhead, inability to run pressure gauges into the bottom of the well, and incomplete pressure measurement data. Achieve the effect of avoiding the lack of pressure data, strong practicability, and solving excessive cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

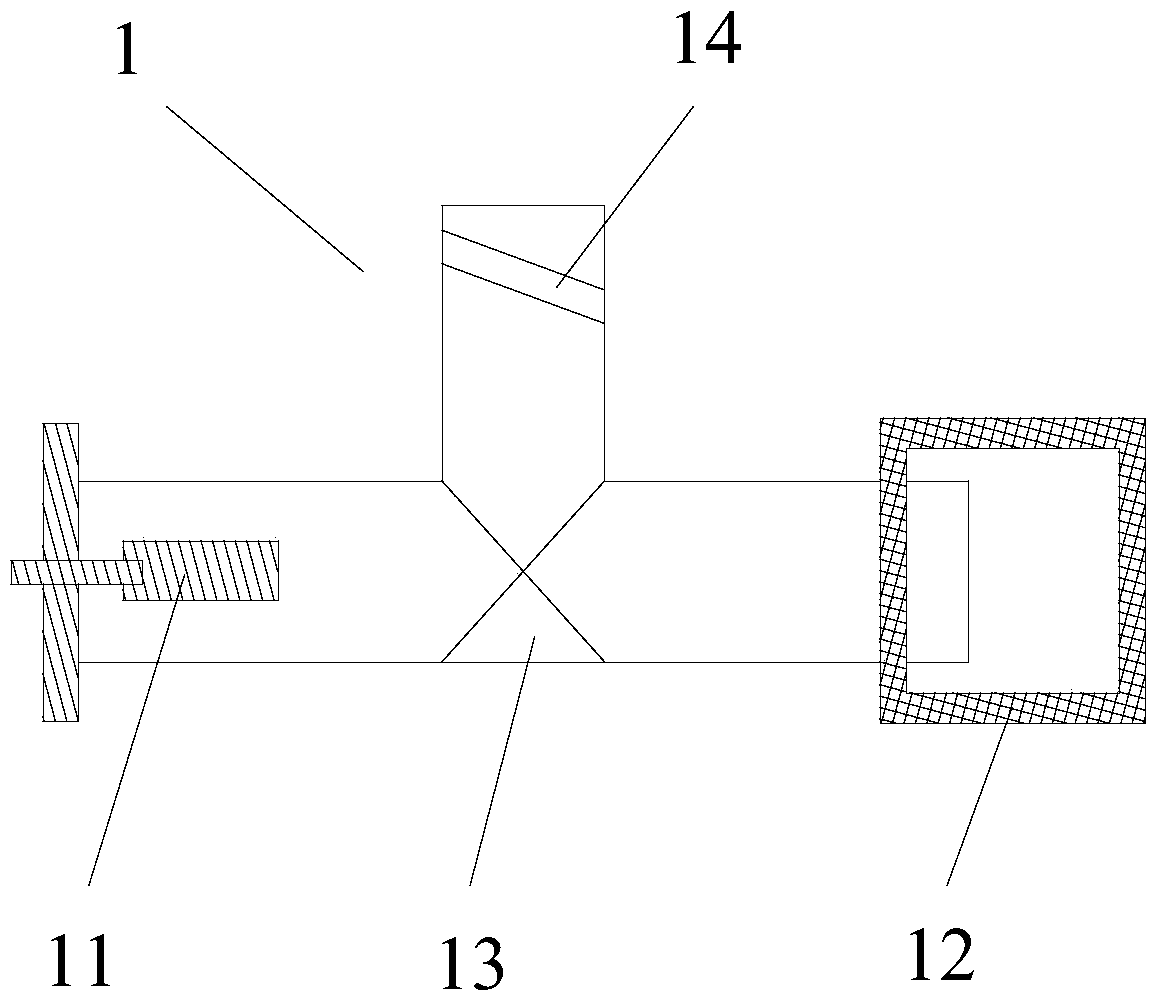

[0034] Such as figure 1 As shown, according to an embodiment of the wellhead combination testing device 1 for water injection wells of the present invention, it includes a high-precision pressure monitor 11, a continuous liquid level monitor 12 and a three-way valve 13, and the high-precision pressure monitor 11 It is combined with the continuous liquid level monitor 12 and the three-way valve 13; the wellhead combined testing device 1 is installed on the pipeline of the injection layer.

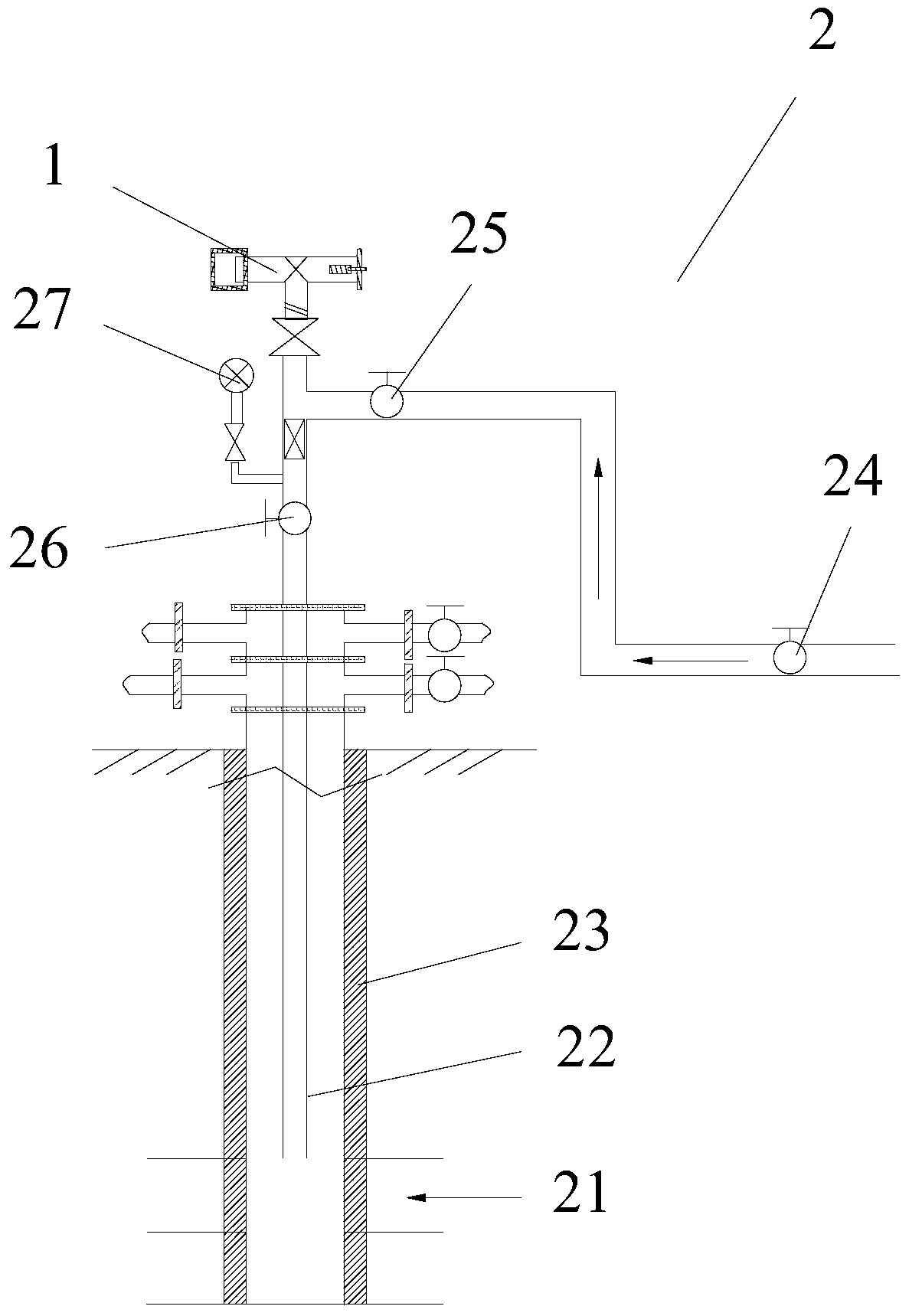

[0035] Such as figure 2 As shown, the injection well 2 of this embodiment has an injection layer 21, and a wellhead combination testing device 1 is installed on the pipeline of the injection layer 21. The injection well 2 is provided with an oil pipe 22 and a casing 23 from inside to outside, and the injection layer 21 is at the bottom of the oil pipe 22 . The injection well 2 is provided with a shut-off valve I24, a shut-off valve II25, a main valve 26 and a pressure gauge 27. The conne...

Embodiment 2

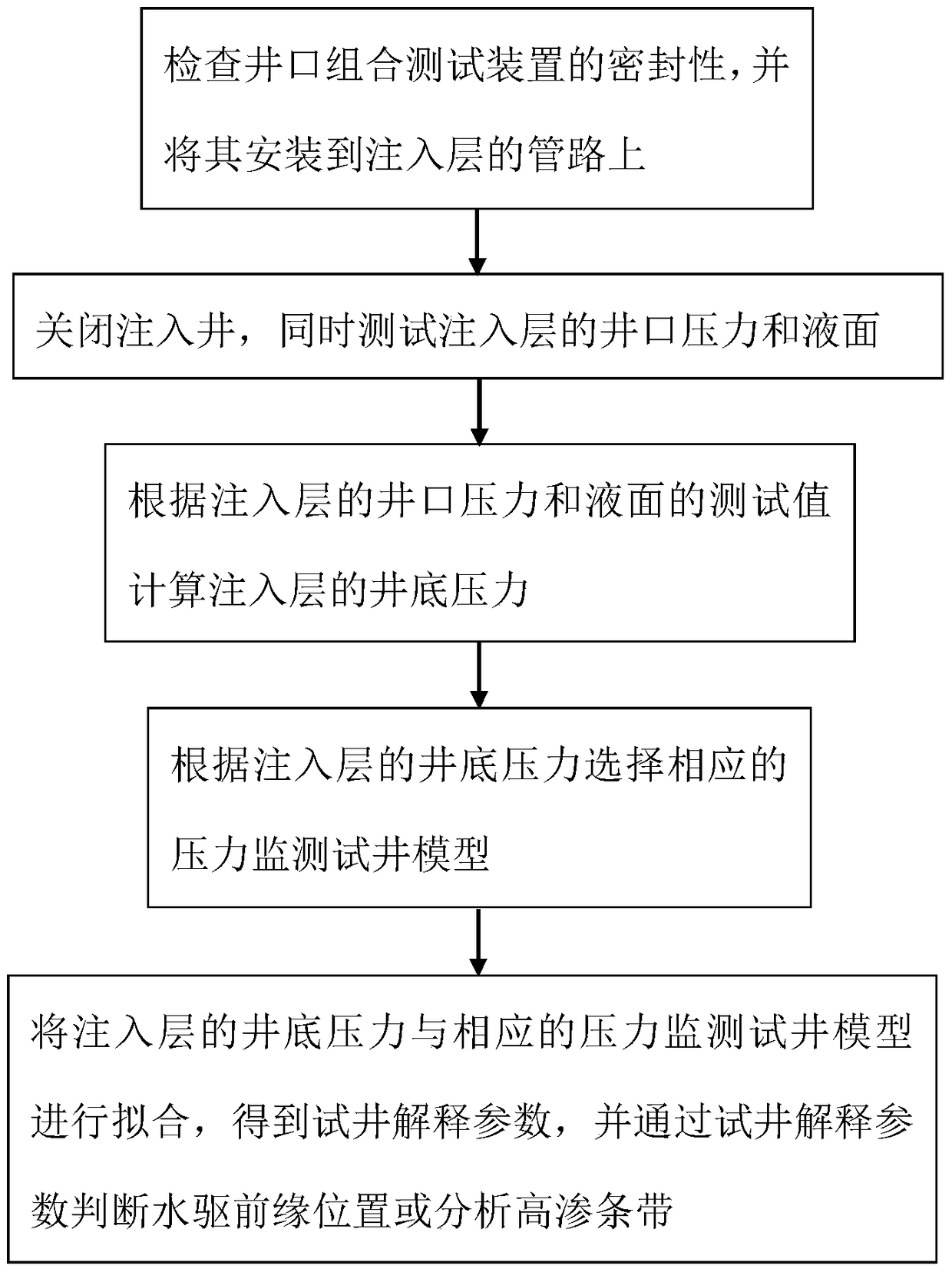

[0054] According to the wellhead combination test device and method for water injection wells of the present invention, the structure, operation process, principle and beneficial effect of the device are the same as those in Embodiment 1, the difference is: in the step 5, the injection layer The well test interpretation parameters are obtained by fitting the bottom hole pressure with the corresponding pressure monitoring well test model, and the hyperpermeable zone is analyzed through the well test interpretation parameters. The fitting curve between the bottom hole pressure of the injection layer and the corresponding pressure monitoring well test model is as follows: Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com