A hand starter for an internal combustion engine

A technology of a starter and an internal combustion engine, which is applied to a starting device with a manual crank, starting an engine, and a machine/engine, etc., can solve the problems of troublesome starting, male labor, and operator danger, and achieves lightening labor intensity and avoiding Friction loss, better sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

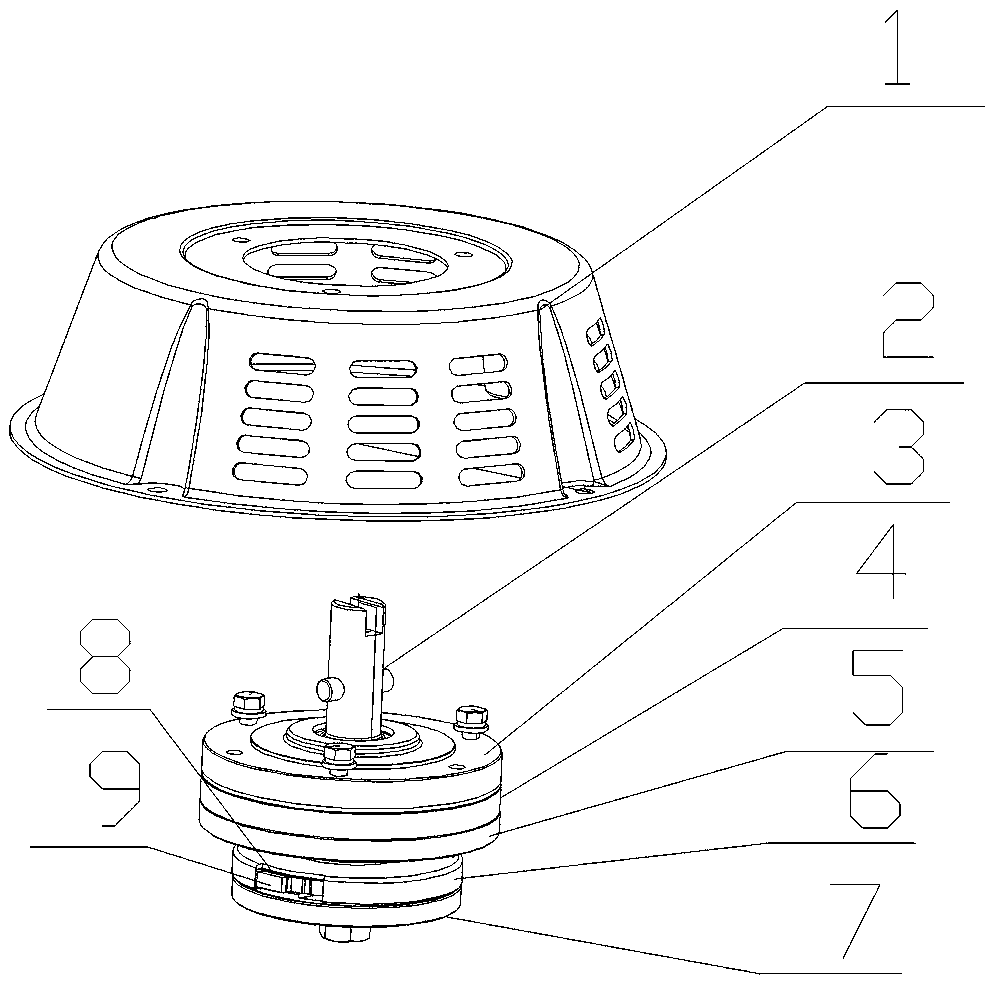

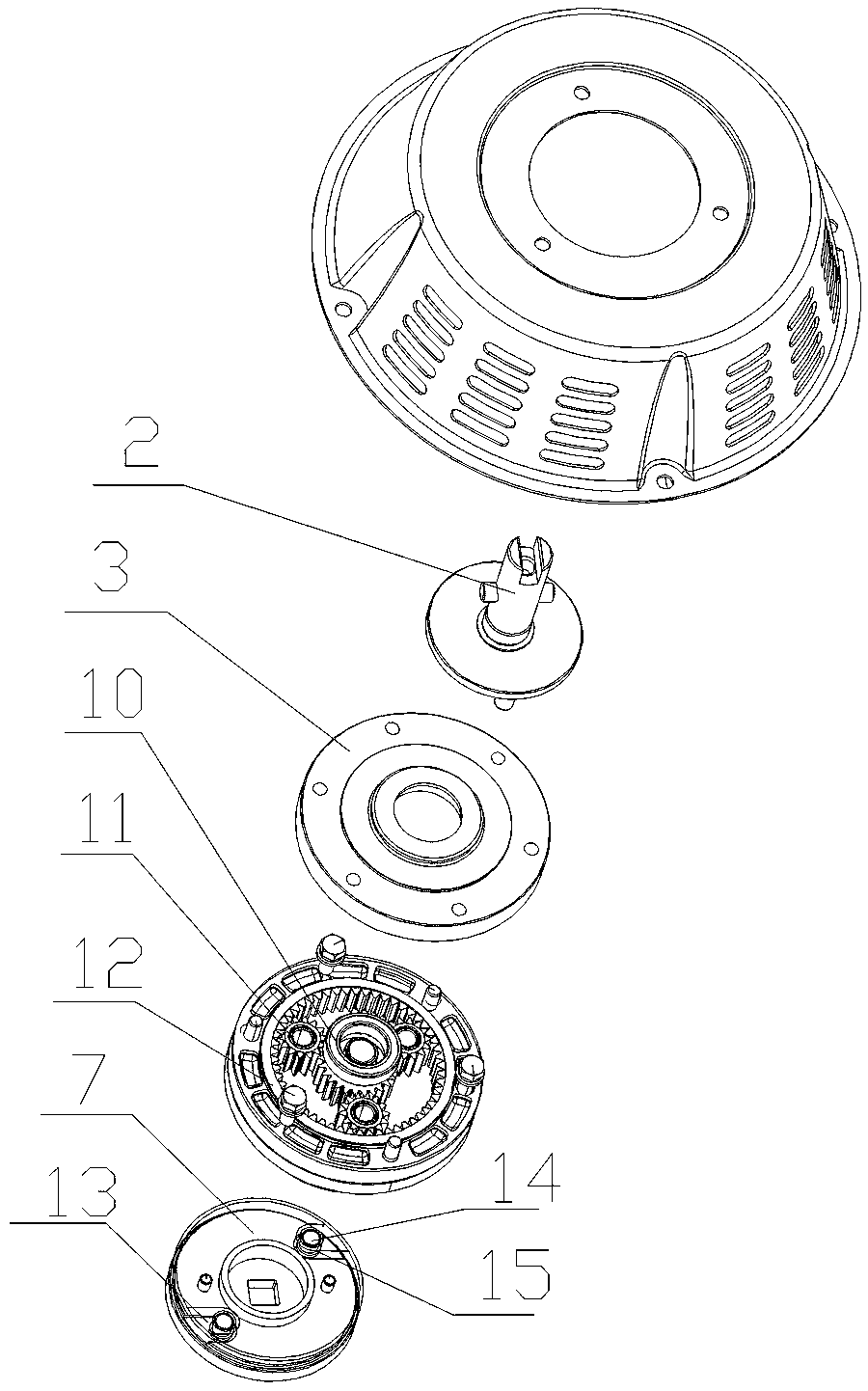

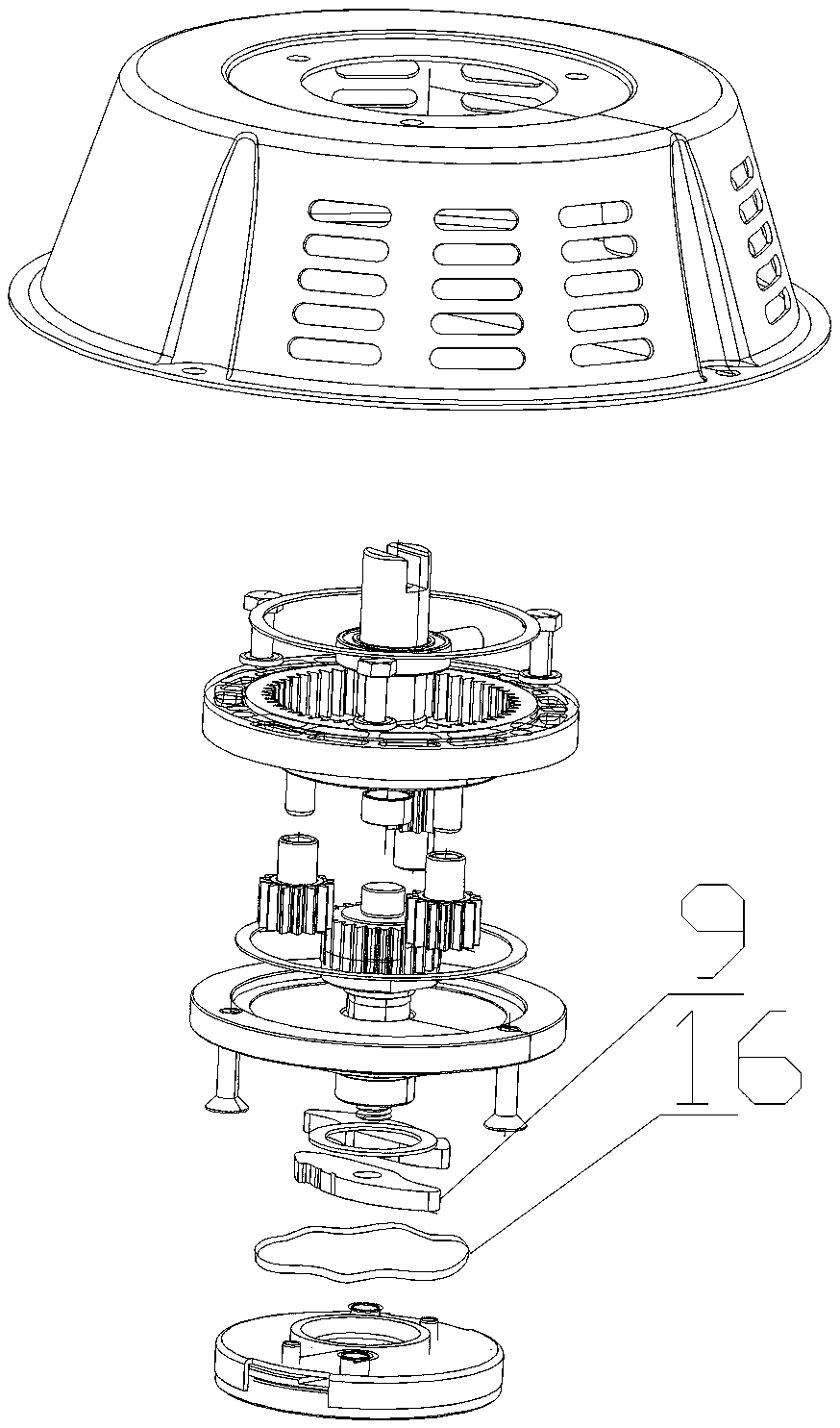

[0025] Such as figure 1 , 2 , Shown in 3 and 4, a kind of internal combustion engine manual starter, comprises housing 1, is used for connecting the cranking handle and is used to connect the input shaft 2 that rocking handle drives to rotate and transmission connects input shaft and is used for starting the starting pawl 9 of internal combustion engine starting plate, The input shaft 2 is connected to a central shaft 17 after the planetary gear assembly 4 speeds up, such as figure 2 As shown, the planetary gear assembly includes a planet carrier 12 , a planetary pinion 11 and a sun gear 10 , the input shaft 2 is connected to the planetary pinion 11 of the planetary gear assembly, and the central shaft 17 is connected to the sun gear 10 of the planetary gear assembly. The outer side and the inner side of the planetary gear assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com