Automatic dust-free slag removing machine for smelting magnesium through Pidgeon process

A technology of slag removal machine and magnesium smelting, which is applied in the direction of furnace, electric charge control, lighting and heating equipment, etc. It can solve the problems of long operation time, incomplete slag removal, no dust removal measures, etc., and achieves simple structure, low cost and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

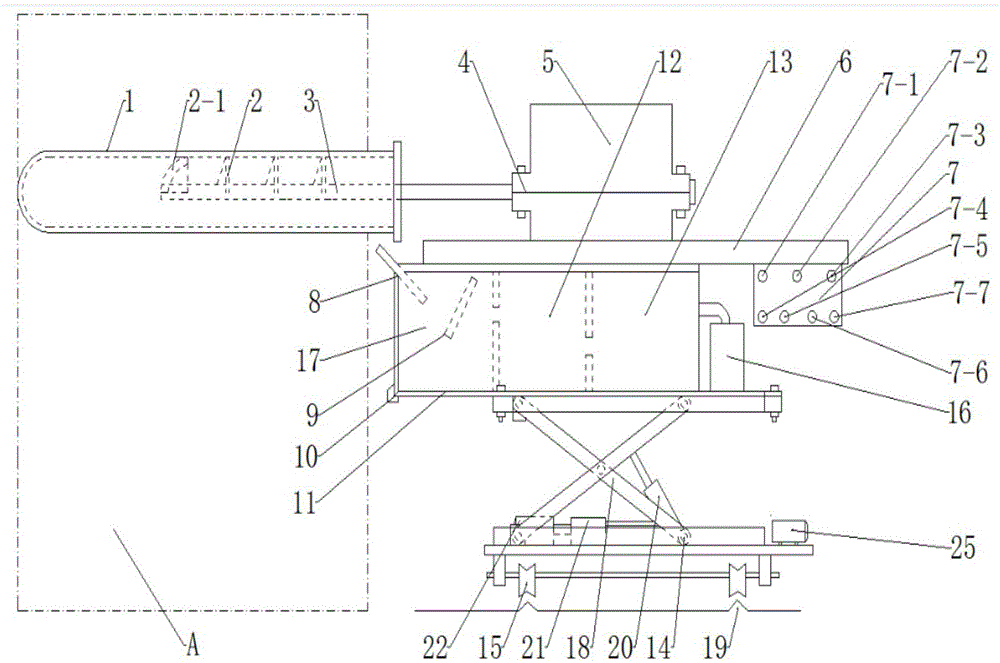

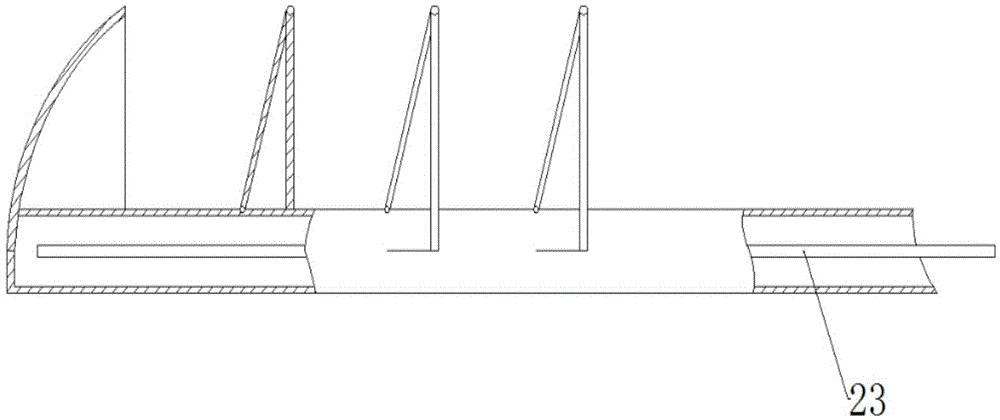

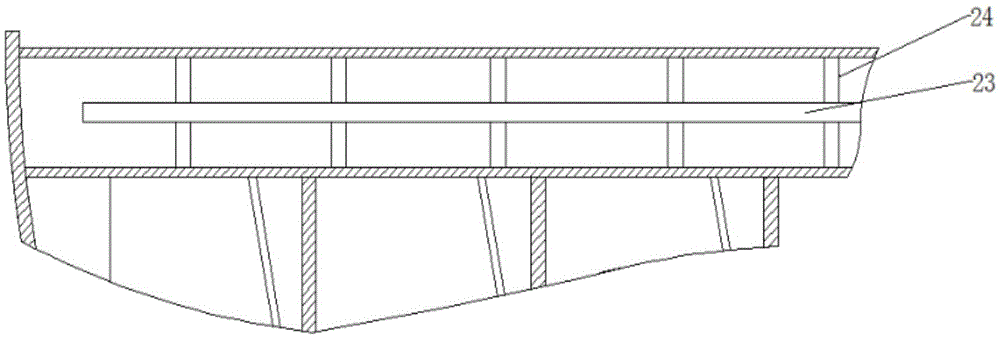

[0032] Example 1: Single reduction tank slag removal operation

[0033] The single-axis Pidgeon method for magnesium smelting dust-free automatic slagging machine, the procedure for achieving dust-free operation is: the dust-free automatic slagging machine uses the slagging machine walking wheel 15 on the fixed slag machine track 19 in front of the workshop magnesium furnace to pass The hydraulic scissor undercarriage 18 controls the motor 22, the oil pump 21, and the oil cylinder 20 to move the movable wheels of the hydraulic scissor undercarriage, adjust the height of the hydraulic scissor undercarriage 18, and make the main shaft 3 of the slag loader align with the center of the reduction tank 1. The slag receiving sliding plate 8 of the dust-free slag box is located below the opening of the reduction tank. If you press the start switch 7-1 and the automatic switch 7-2 on the control box 7. The main shaft 3 of the slag scraper is pushed by the main shaft action chassis 5 alon...

Embodiment 2

[0034] Example 2: Slag-skimming operation on reduction tanks with different arrangement heights

[0035] Due to the small width of the slag raking machine, it is suitable for two side-by-side use, which can realize the slag removal of the two reduction tanks, one high and one low: two dust-free automatic slagging machines are arranged side by side in front of the magnesium smelting furnace in the workshop On the fixed slag machine track 19, the slag scraper travel wheel 15 is used to move, and the hydraulic scissor landing gear 18 controls the motor 22, the oil pump 21, and the oil cylinder 20 to move the movable wheels of the hydraulic scissor landing gear to adjust the height of the hydraulic scissor landing gear 18. , The main shaft 3 of the slag scraper is aligned with the center of the reduction tank 1, and the slag receiving slide 8 of the dust-free slag box is under the opening of the reduction tank 1. If you press the start switch 7-1 and the automatic switch 7-2 on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com