Detection Method of Periodic Defects on the Surface of Rolled Materials During Calendering

A calendering material and calendering process technology, applied in the field of material surface optical detection, can solve the problems of low detection rate of magnetic field detection method, missed detection of periodic defects, misjudgment of periodic defects, etc., to facilitate application and maintenance, and input data Less, improve the effect of missed detection rate and false defect false detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

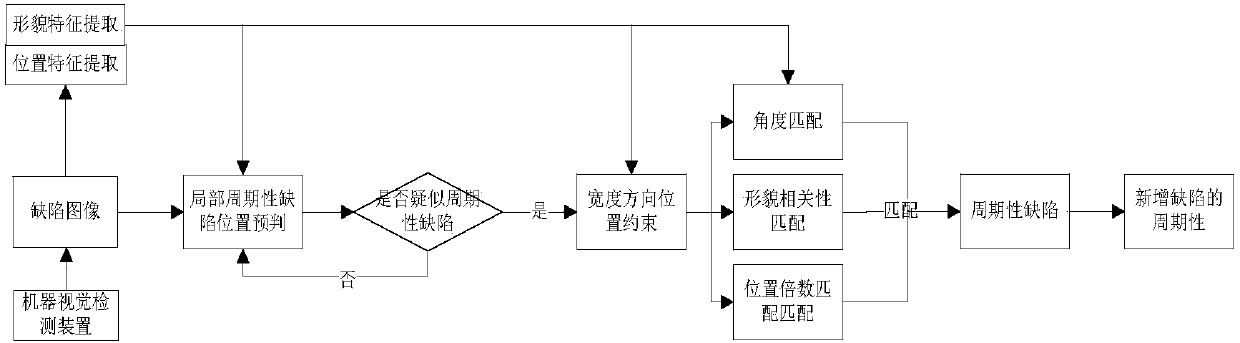

Method used

Image

Examples

Embodiment

[0117] Periodic defect detection on steel surface

[0118] In this embodiment, the steel material is cold-rolled silicon steel, and five sets of defect image data are taken, including different types of periodic defect images and non-periodic defect images, see Figure 7-11 . Table 1 shows the results of defect detection in the examples. The number of missed detections refers to the number of periodic defects misjudged as non-periodic defects, and the number of false detections refers to the number of non-periodic defects misjudged as periodic defects.

[0119] Image 6 The schematic diagram of periodic defect distribution is shown, in which, figure (a) is an ideal periodic defect distribution. Due to changes in external factors such as rolling process, acquisition environment, and equipment vibration, two other common periodic defect distributions will result: The distribution of vacancy-type periodic defects shown in figure (b) and the distribution of offset-type periodic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com