projection optical system

A projection optical system and projection direction technology, applied in the field of optical system design of projection equipment, can solve the problems of low light utilization rate and complex system structure, simplify the cooling system, reduce the complexity of the system, improve the light utilization rate and projection brightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

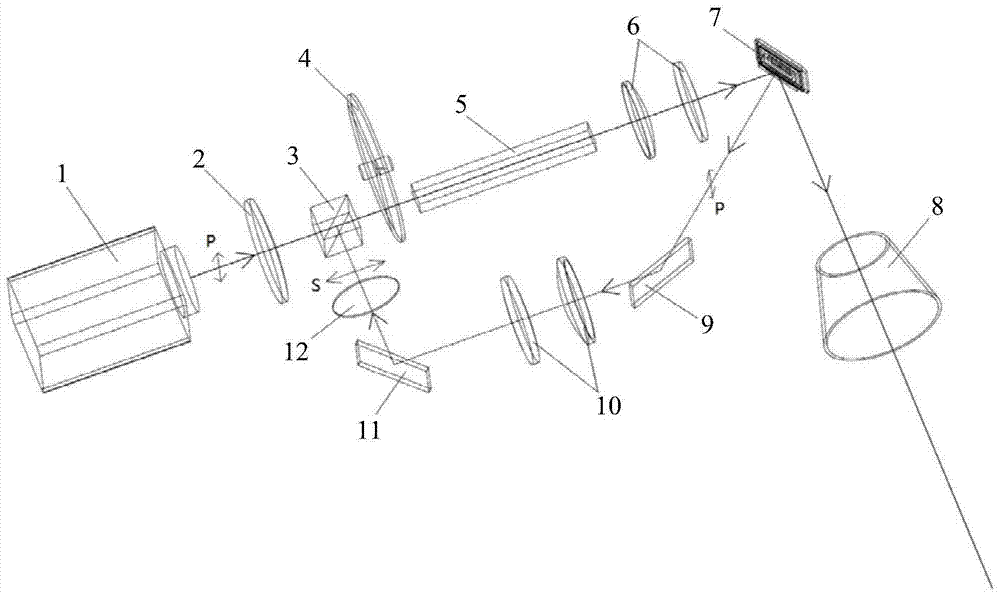

[0019] See attached figure 1 , the projection optical system of the present invention comprises a laser light source 1, a converging mirror 2, a polarization beam splitter prism 3, a color wheel 4, an integrating square rod 5, a relay mirror group A6, a DMD7, a projection lens 8 and a folding mirror group;

[0020] The polarized light P emitted by the laser light source 1 is converged by the converging mirror 2 and then transmitted by the polarizing beam splitter prism 3, and the polarized light P transmitted by the polarizing beam splitting prism 3 enters the DMD7 through the color wheel 4, the integrating square rod 5 and the relay mirror group A6 in sequence Above, the outgoing light in the projection direction of DMD7 exits through the projection lens 8, and the outgoing light in the non-projection direction of DMD7 passes through the folding mirror ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com