Built-in permanent-magnet synchronous motor

A permanent magnet synchronous motor technology, applied to synchronous motors with stationary armatures and rotating magnets, synchronous machines, synchronous machine parts, etc., to achieve the effects of improving performance, reducing torque ripple, and improving the effect of magnetic concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be further explained below in conjunction with the accompanying drawings.

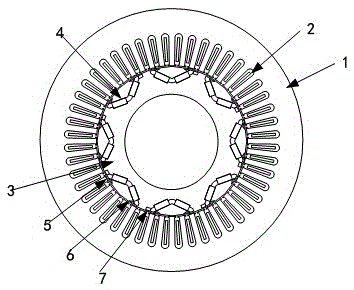

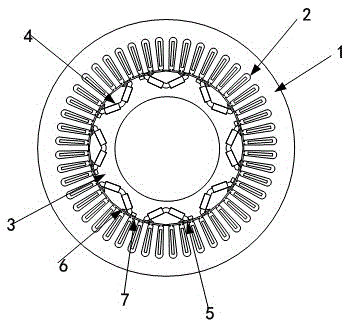

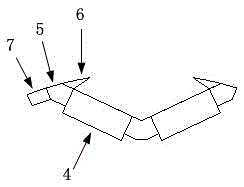

[0021] Such as figure 1 and image 3 As shown, an interior permanent magnet synchronous motor according to an embodiment of the present invention includes a stator 1 , an armature winding 2 and a rotor 3 . The armature winding 2 is wound on the teeth of the stator 1 in a distributed manner, and the rotor 3 is located in the cavity of the stator 1; the rotor 3 is provided with a V-shaped permanent magnet 4 arranged along the circumference of the rotor 3, and the two ends of the permanent magnet 4 towards stator 1. In each permanent magnet 4 , first magnetic barriers 5 are provided at both ends of the permanent magnet 4 , and a magnetic barrier group is provided outside and inside the permanent magnet 4 .

[0022] As a preferred example, each of the magnetic barrier groups includes two second magnetic barriers 6 and a third magnetic barrier 7, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com