AC brushless electro-magnetic starter generator employing concentrated windings

A technology of starting generators and concentrated windings, applied in windings, electromechanical devices, electrical components, etc., can solve the problems of increased friction between the rotating shaft and auxiliary bearings, shortened motor service life, increased difficulty, etc., and achieves small torque ripple and increased Low torque density, vibration and noise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

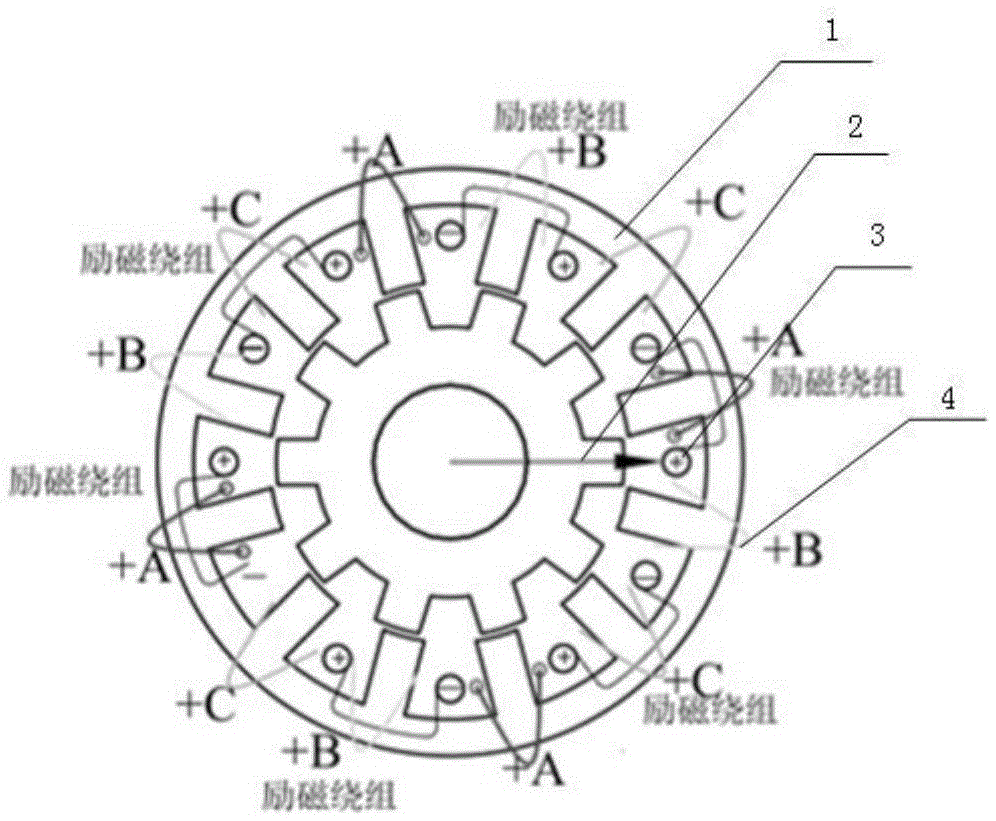

[0026] Such as figure 1 Among them, the concentrated winding AC brushless electric excitation starter generator realized according to the present invention includes: rotor core 2, field winding 3, armature winding 4, and stator core 1 from inside to outside in the radial direction.

[0027] Stator slot structure such as figure 1 As shown, the field winding 3 and the armature winding 4 in the stator slot should be separated by interphase insulation. When off-line, the double-layer armature winding 4 should be placed first, and then the field winding 3 should be placed.

[0028] Among them, the stator and rotor of the brushless electric excitation AC starter generator of the present invention use 0.1--0.2mm silicon steel sheet as its material to reduce iron consumption.

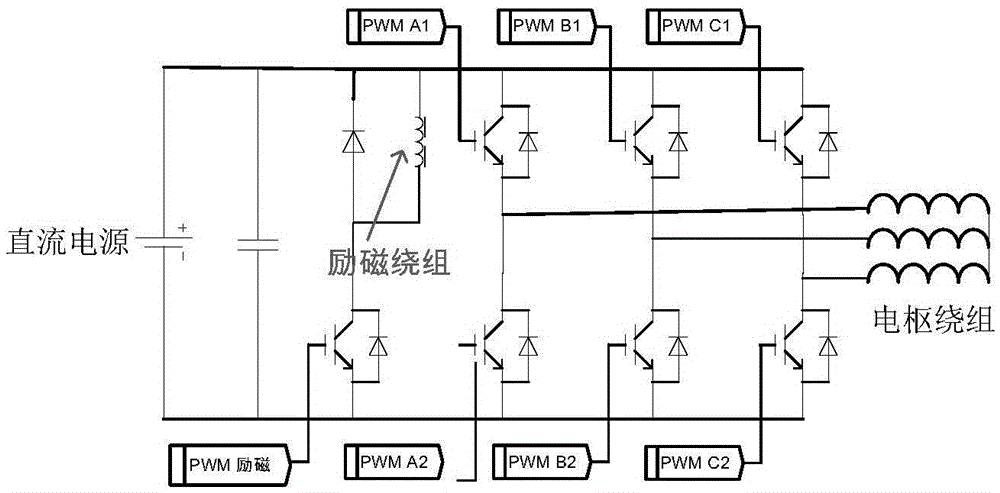

[0029] The block diagram of the corresponding control drive system based on the brushless electric excitation starter generator is as follows: figure 2 shown. When starting, the armature winding 4 of the m...

Embodiment 2

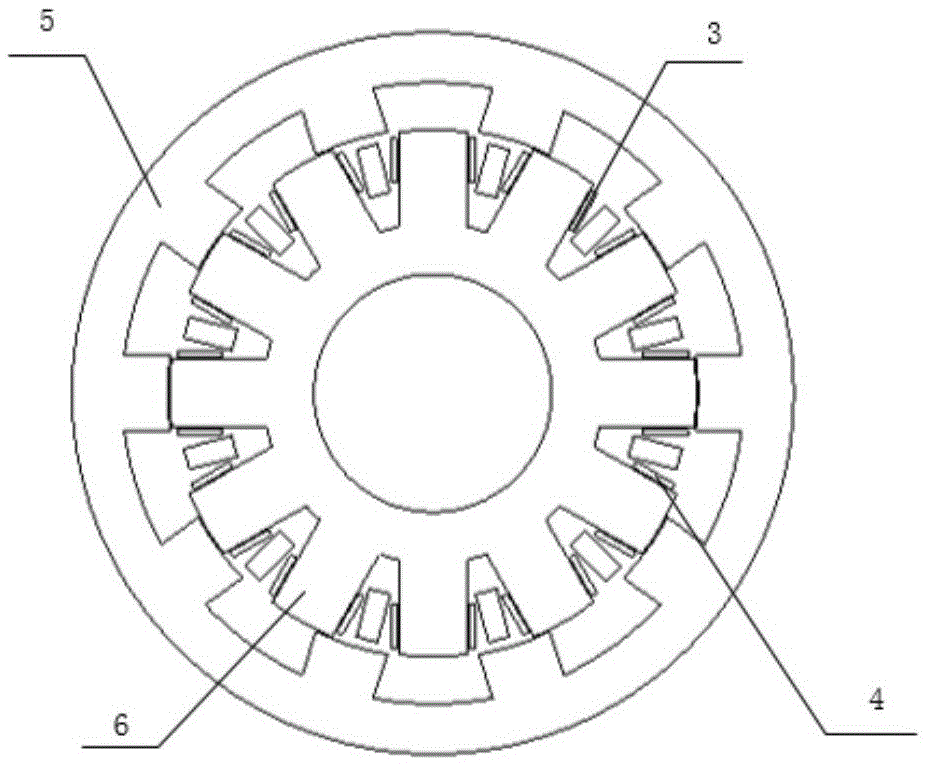

[0031] The outer rotor motor structure based on the above electromagnetic principle can also accomplish the purpose of the invention. The structure diagram is as follows image 3As shown, 5 is the outer rotor core, 6 is the inner stator core, 3 is the field winding, and 4 is the armature winding. In addition, the outer rotor structure features a larger air gap radius and higher torque density

[0032] In this embodiment, an open slot stator and rotor punching structure is adopted;

[0033] The stator excitation winding 3 and the armature winding 4 are separated by interphase insulating materials, and the partitions are evenly placed in each stator slot, and the windings are all single-tooth winding concentrated windings;

[0034] The excitation winding 3 is controlled by a controllable DC power supply, and the armature winding 4 is controlled by a three-phase inverter during the starting process, and is switched to a rectifier circuit during power generation operation.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com