Fermented milk and preparation method thereof

A technology of fermented milk and preparation process, which is applied in the direction of bacteria and lactobacillus used in dairy products and food preparation, which can solve the problems of strange taste of fermented milk, inability to meet the different taste needs of consumers, and poor consumer acceptance. Achieve the effect of fresh and natural flavor, delicate texture and unique taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

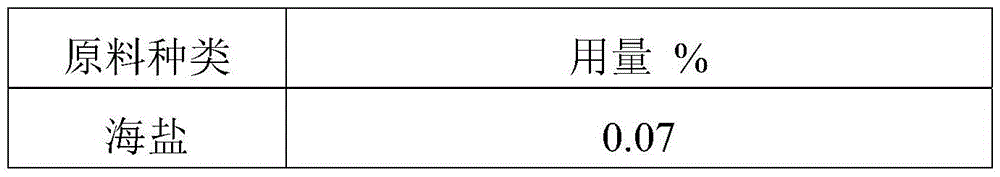

[0047] 1. The formula is as described in Table 1 (by mass percentage):

[0048] Table 1

[0049]

[0050]

[0051] 2. Preparation method:

[0052] (1) Mix sea salt, white sugar, whey protein powder, and cream evenly, dissolve in raw milk at 40°C, and stir for 30 minutes.

[0053] (2) The first-stage homogenization pressure is 16MPa, the second-stage homogenization pressure is 3MPa, the homogenization temperature is 65°C, the sterilization time is 10min at 85°C after homogenization, and cooled to 45°C.

[0054] (3) Inoculate the starter and other probiotics, stir at 45°C and 200rpm for 5 minutes, then ferment at 45°C until the final acidity is 65°T, and the fermentation time is about 4 hours.

[0055] (4) Turn over the vat with a back pressure of 0.5MPa, cool to 20°C, add lemon jam and lemon essence online, and fill at 20°C, and post-ripen the fermented milk for 10 hours at 10°C.

[0056] The texture of the product obtained in this embodiment is fine and smooth, and th...

Embodiment 2

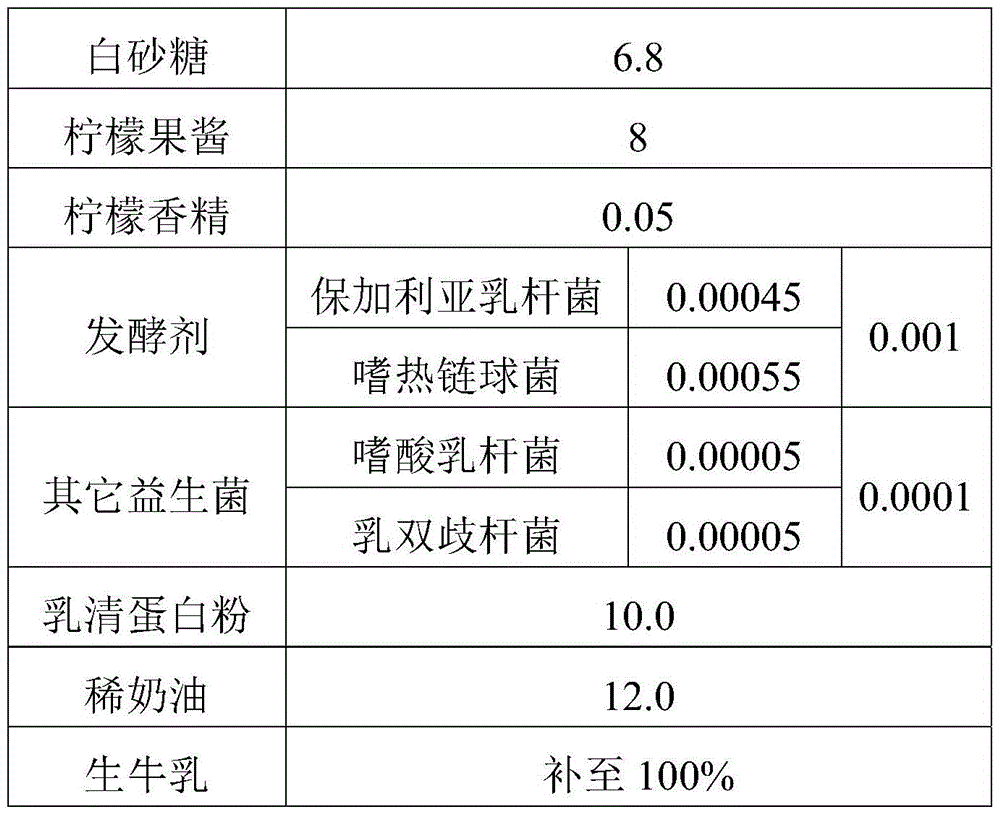

[0058] 1. The formula is as described in Table 2 (by mass percentage):

[0059] Table 2

[0060]

[0061]

[0062] 2. Preparation method:

[0063] (1) Mix lake salt, white sugar, whey protein powder and cream evenly, dissolve in raw milk at 50°C, and stir for 15 minutes.

[0064] (2) The first-stage homogenization pressure is 17MPa, the second-stage homogenization pressure is 3MPa, the homogenization temperature is 68°C, the sterilization time is 5min at 95°C after homogenization, and cooled to 37°C.

[0065] (3) Inoculate the starter and other probiotics, stir at 37°C and 100rpm for 10 minutes, then ferment at 37°C until the final acidity is 70°T, and the fermentation time is about 7 hours.

[0066] (4) Turn over the vat with a back pressure of 0.3MPa, cool to 16°C, add lemon jam and lemon essence online, and fill at 16°C, and post-ripen the fermented milk at 6°C for 12 hours.

[0067] The texture of the product obtained in this embodiment is fine and smooth, and the...

Embodiment 3

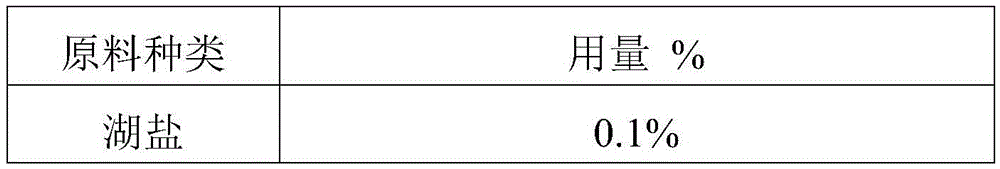

[0069] 1. The formula is as described in Table 3 (by mass percentage):

[0070] table 3

[0071]

[0072]

[0073] 2. Preparation method:

[0074] (1) Mix sea salt and white sugar evenly, dissolve in raw milk at 45°C, and stir for 20 minutes.

[0075] (2) The primary homogenization pressure is 16.5MPa, the secondary homogenization pressure is 4MPa, the homogenization temperature is 58°C, the sterilization time is 8min at 90°C after homogenization, and cooled to 42°C.

[0076] (3) Inoculate the starter, stir at 42°C and 150rpm for 8 minutes, then ferment at 42°C until the final acidity is 75°T, and the fermentation time is about 6 hours.

[0077] (4) Turn over the vat with a back pressure of 0.4MPa, cool to 22°C, add lemon jam and lemon essence online, and fill at 22°C, and post-ripen the fermented milk at 2°C for 15 hours.

[0078] The texture of the product obtained in this embodiment is fine and smooth, and the combination of light salty and lemon flavor makes it cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com