Octapeptide modified dexamethasone, preparation, nanostructure and application

A technology of dexamethasone and -his-gly-glu, which is applied in the field of biomedicine and can solve the problems of no obvious improvement in curative effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

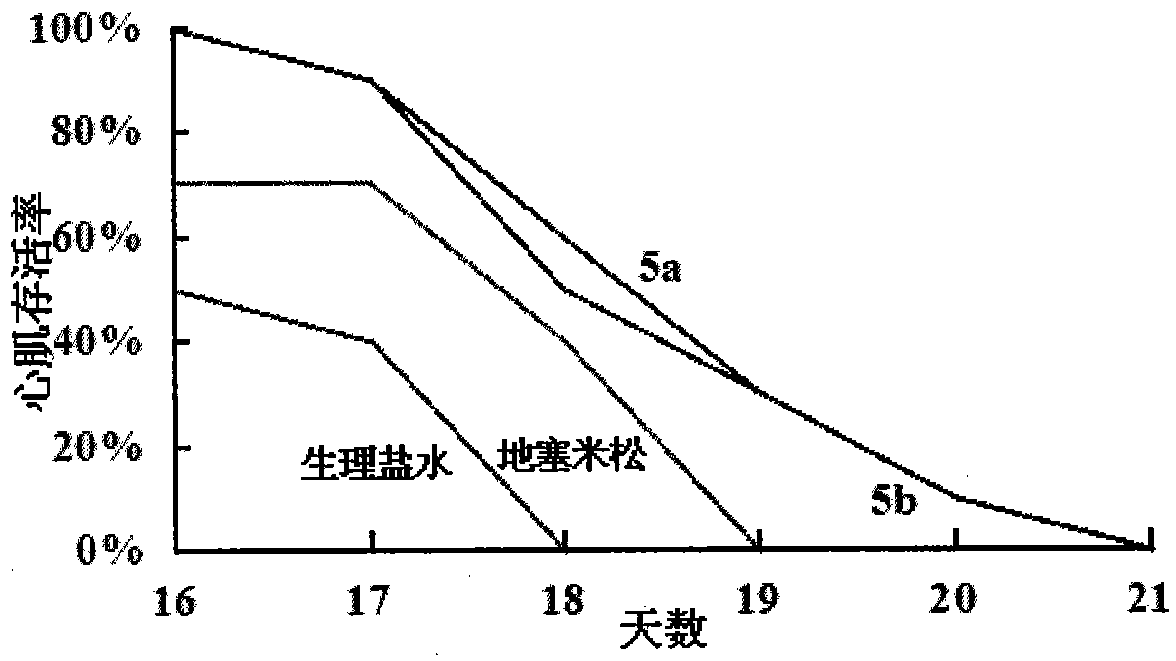

AI Technical Summary

Problems solved by technology

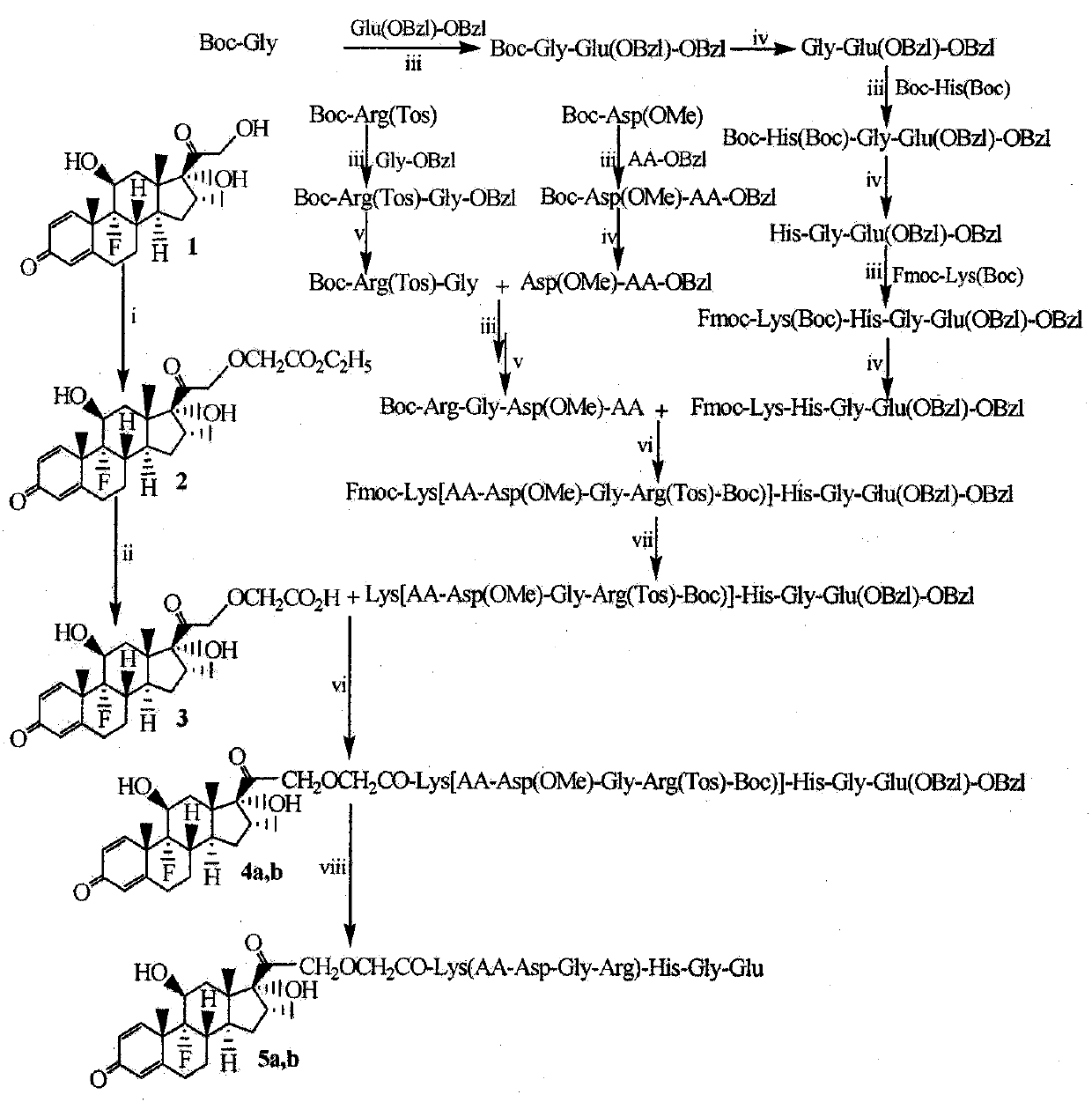

Method used

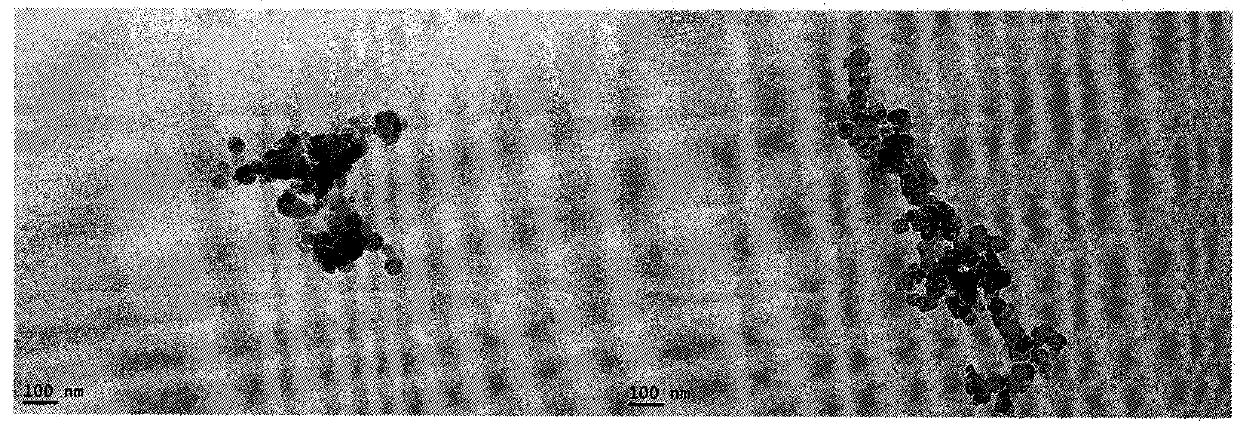

Image

Examples

Embodiment 1

[0026] Example 1 Preparation of Boc-Gly-Glu(OBzl)-OBzl

[0027] Weigh (30.0mmol) 5.294g (30.0mmol) of Boc-Gly, 4.353g (32.5mmol) of HOBt, dissolve in dry tetrahydrofuran (THF), stir under an ice bath, add dropwise 7.406g (35.9mmol) of DCC dissolved in THF, and activate 30 After 5 minutes, 15.572g (31.3mmol) TosH·Glu(OBzl)-OBzl was added, NMM adjusted pH=8, reacted at room temperature for 12 hours, TLC(CH 2 Cl 2 / MeOH=20 / 1), indicating that the raw material points disappeared. DCU was removed by filtration, the filtrate was concentrated under reduced pressure, and the residue was dissolved in 200 mL of ethyl acetate. The ethyl acetate solution obtained was sequentially used with 50 mL of saturated sodium bicarbonate aqueous solution, 50 mL of saturated sodium chloride aqueous solution, 50 mL of saturated potassium hydrogen sulfate aqueous solution, and 50 mL of saturated chlorine Washed with sodium chloride aqueous solution, 50 mL saturated sodium bicarbonate aqueous solution, 50 ...

Embodiment 2

[0028] Example 2 Preparation of HCl·Gly-Glu(OBzl)-OBzl

[0029] To 13.0g (26.9mmol) Boc-Gly-Glu(OBzl)-OBz under ice bath was added 200mL 4M ethyl acetate solution of hydrogen chloride, after reaction for 2 hours, TLC(CH 2 Cl 2 / MeOH=20 / 1) shows the disappearance of raw material spots. Concentrate under reduced pressure. The residue was dissolved in anhydrous ethyl acetate and concentrated under reduced pressure. This operation was repeated 3 times. The residue was dissolved with anhydrous ether and concentrated under reduced pressure. This operation is also repeated 3 times. 12.5 g (96.1%) of the title compound was obtained.

Embodiment 3

[0030] Example 3 Preparation of Boc-His(Boc)-Gly-Glu(OBzl)-OBzl

[0031] Weigh 1.400g (3.9mmol) Boc-His(Boc), 0.561g (4.0mmol) HOBt, dissolve in dry tetrahydrofuran (THF), stir under ice bath, add dropwise 0.975g (4.7mmol) DCC dissolved in THF, After stirring and activating for 30 minutes, add 2.0g (4.8mmol) HCl·Gly-Glu(OBzl)-OBzl, adjust pH=8 by NMM, react at room temperature for 12 hours, TLC(CH 2 Cl 2 / MeOH=20 / 1), indicating that the raw material points disappeared. DCU was removed by filtration, the filtrate was concentrated under reduced pressure, and the residue was dissolved in 100 mL of ethyl acetate. The ethyl acetate solution obtained was successively used with saturated sodium bicarbonate 20 mL saturated sodium bicarbonate aqueous solution, saturated 20 mL sodium chloride aqueous solution, and 20 mL saturated potassium hydrogen sulfate aqueous solution. , 20mL saturated sodium chloride aqueous solution, 20mL saturated sodium bicarbonate aqueous solution, 20mL saturated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com