Oxygen blast furnace and gas-based shaft furnace joint production system and joint production method

A gas-based shaft furnace and combined production technology, applied in the field of metallurgy, can solve problems such as restrictions, high costs, and high pollution, and achieve the effect of solving insufficient oxygen blast furnace top gas circulation and eliminating high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

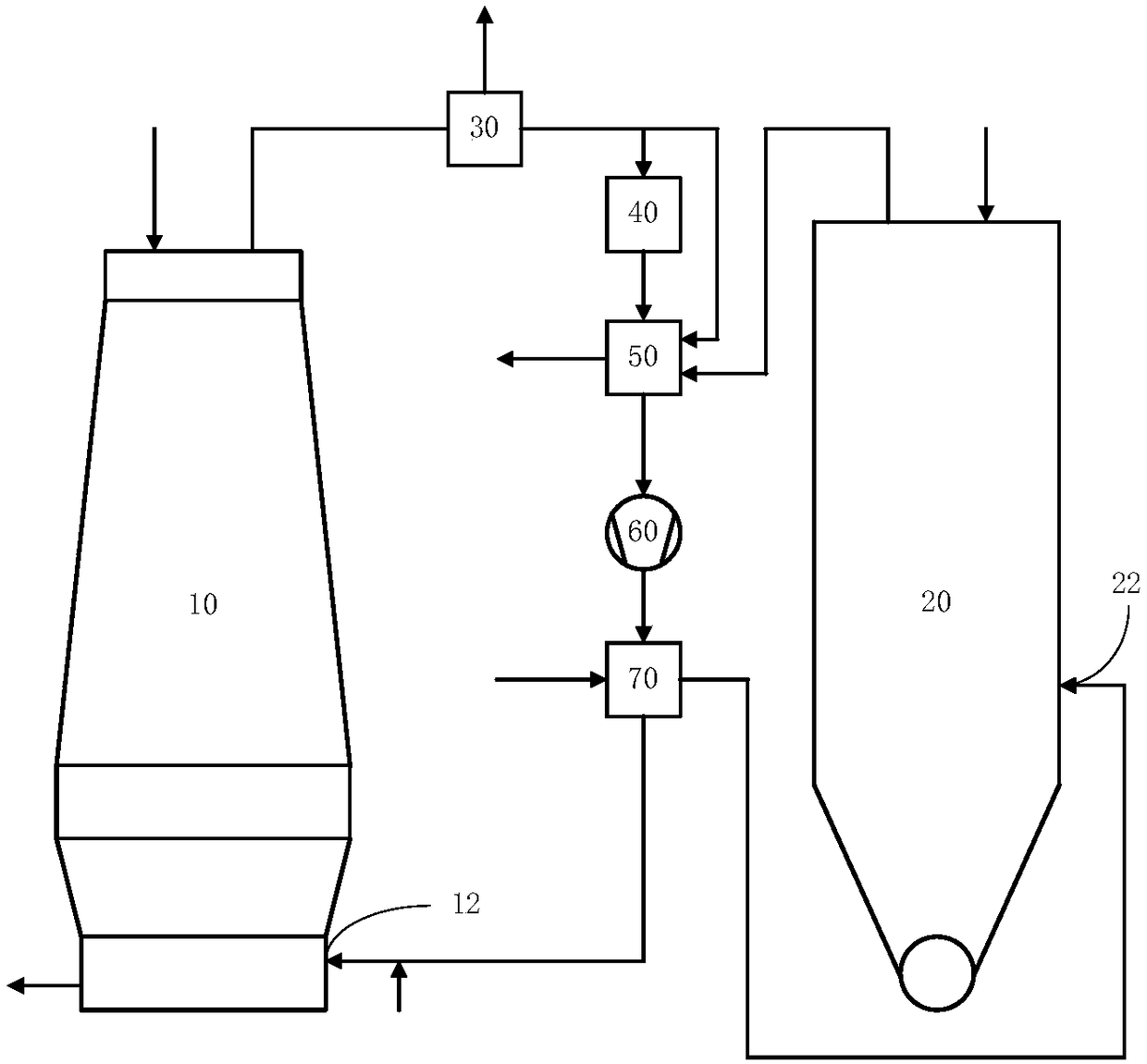

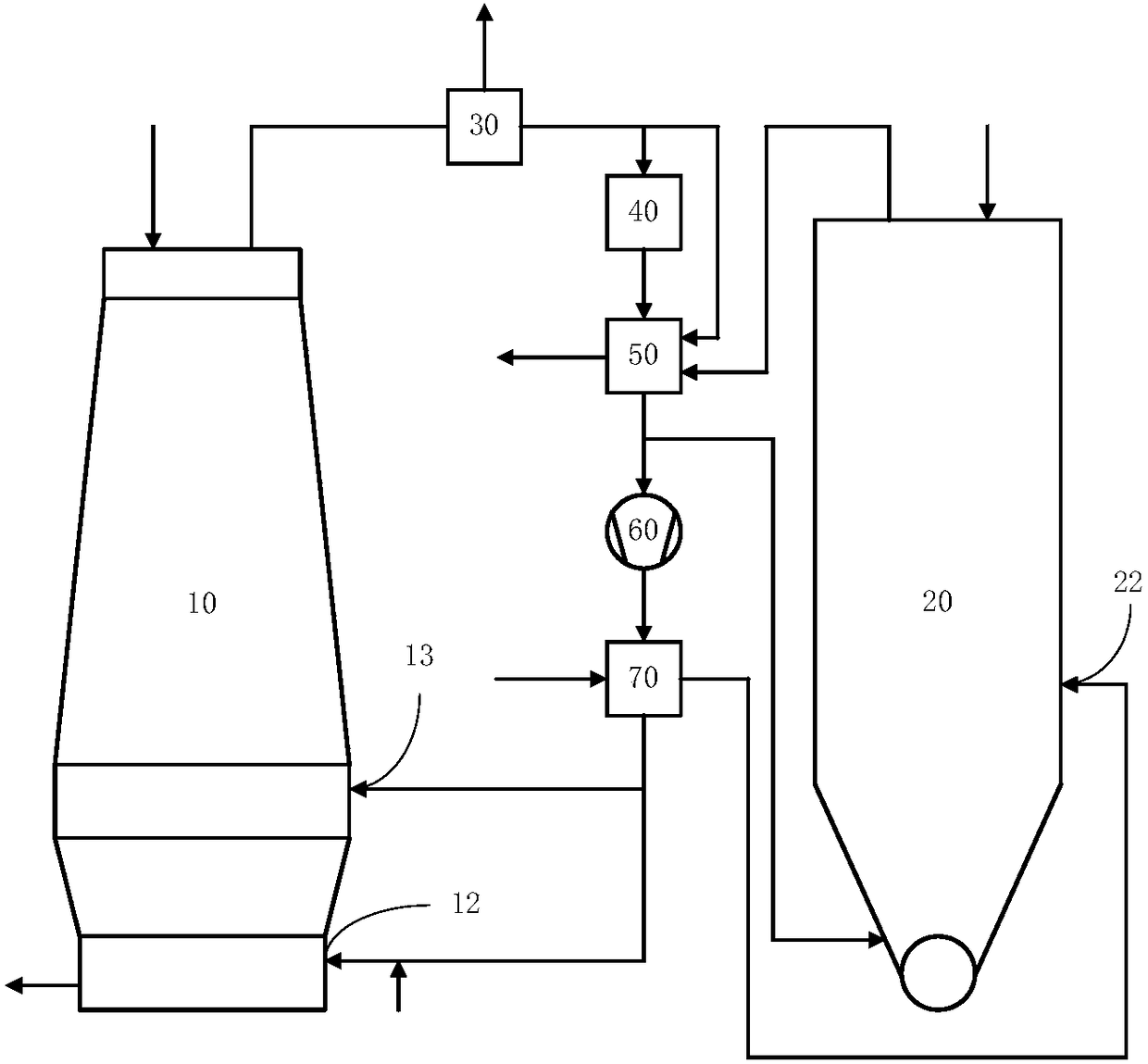

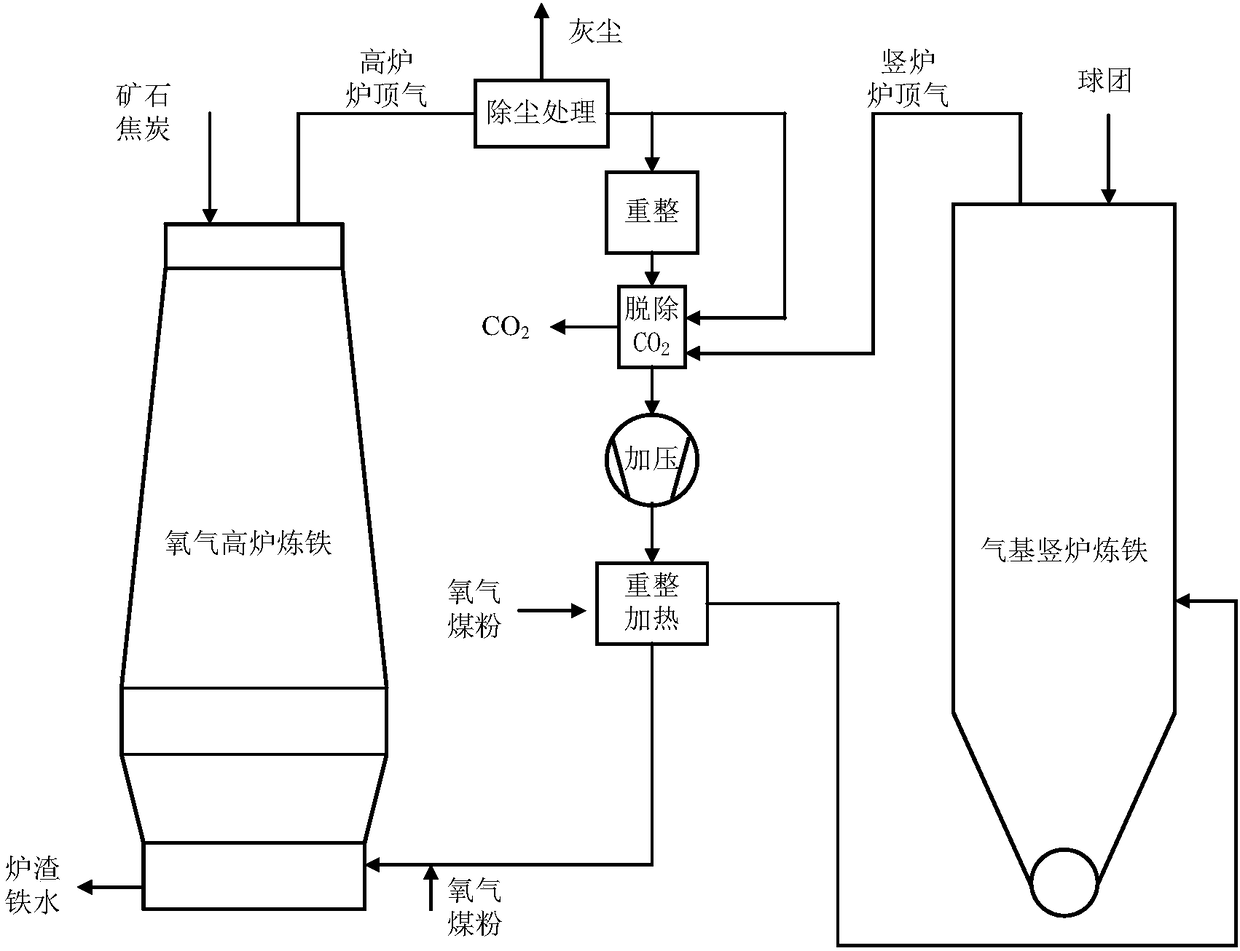

[0099] reference figure 2 with 4 , The specific production system and method of oxygen blast furnace and gas-based shaft furnace are:

[0100] 1) After the top gas of the oxygen blast furnace 10 is dedusted by the dust removal device 30, the gas is divided into two parts. The first part of the gas enters the water gas shift device 40 to produce H 2 , Then enter CO 2 Removal device 50, the second part of gas directly enters CO 2 Removal device 50, two parts of gas and gas-based shaft furnace top gas are mixed to remove part of CO 2 . After that, the gas is divided into two parts again. One part enters the gas-based shaft furnace 20 through the nozzle at the bottom of the gas-based shaft furnace (cooling gas inlet), and the remaining part is pressurized by the pressurizer 60 and enters the gasifier 70 together with oxygen and pulverized coal. Reaction, get H 2 / CO = 1~2:1 high temperature reducing gas. A part of the gas is blown into the oxygen blast furnace 10 from the upper air...

Embodiment 2

[0118] It is basically the same as Example 1, except that:

[0119] According to theoretical calculation, 3000m 3 The technical indicators of oxygen blast furnace production are as follows:

[0120] Oxygen consumption of oxygen blast furnace (90% purity): 245Nm 3 / tHM

[0121] Oxygen blast furnace coal ratio: 200kg / tHM

[0122] Oxygen blast furnace coke ratio: 178kg / tHM

[0123] Top gas volume: 1357Nm 3 / tHM

[0124] Top gas composition: CO: 48.4%, CO 2 : 36.9%, H 2 : 8.3%, H 2 O: 2.6%, N 2 : 3.8%

[0125] Oxygen blast furnace output: 12600tHM / d

[0126] Oxygen consumption of gasifier (90% purity): 140Nm 3 / tHM

[0127] Pulverized coal consumption of gasifier: 200kg / tHM

[0128] Circulating gas composition: CO: 44.8%, H 2 : 49.4%, N 2 : 5.8%

[0129] Circulating gas temperature: 1100℃

[0130] Circulating gas volume at the upper exhaust outlet: 382Nm 3 / tHM

[0131] Circulating gas volume at the lower exhaust outlet: 400Nm 3 / tHM

[0132] Gas-based shaft furnace output: 8000tDRI / d

Embodiment 3

[0134] It is basically the same as Example 1, except that:

[0135] According to theoretical calculation, 5000m 3 The technical indicators of oxygen blast furnace production are as follows:

[0136] Oxygen consumption of oxygen blast furnace (95% purity): 225Nm 3 / tHM

[0137] Oxygen blast furnace coal ratio: 200kg / tHM

[0138] Oxygen blast furnace coke ratio: 191kg / tHM

[0139] Top gas volume: 1368Nm 3 / tHM

[0140] Top gas composition: CO: 49.8%, CO 2 : 37.5%, H 2 : 8.6%, H 2 O: 2.6%, N 2 : 1.5%

[0141] Oxygen blast furnace output: 21000tHM / d

[0142] Oxygen consumption of gasifier (95% purity): 121Nm 3 / tHM

[0143] Pulverized coal consumption of gasifier: 180kg / tHM

[0144] Circulating gas composition: CO: 46.8%, H 2 : 50.0%, N 2 : 3.2%

[0145] Circulating gas temperature: 900℃

[0146] Circulating gas volume at the upper exhaust outlet: 382Nm 3 / tHM

[0147] Circulating gas volume at the lower exhaust outlet: 400Nm 3 / tHM

[0148] Gas-based shaft furnace output: 12700tDRI / d

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com