Composite fiber of spices and preparation method and application of composite fiber

A composite fiber and fragrance technology, applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of limited use of fragrance composite fibers, low fragrance content, poor performance, etc., to overcome the volatilization or decomposition of fragrance Effects of attrition, flavor content and species stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

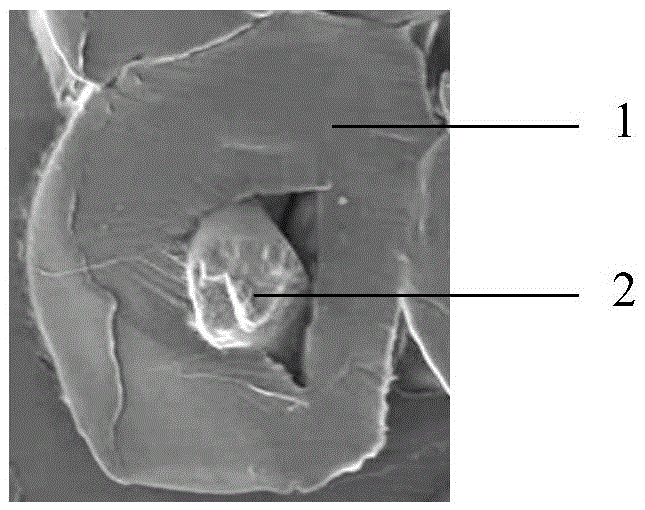

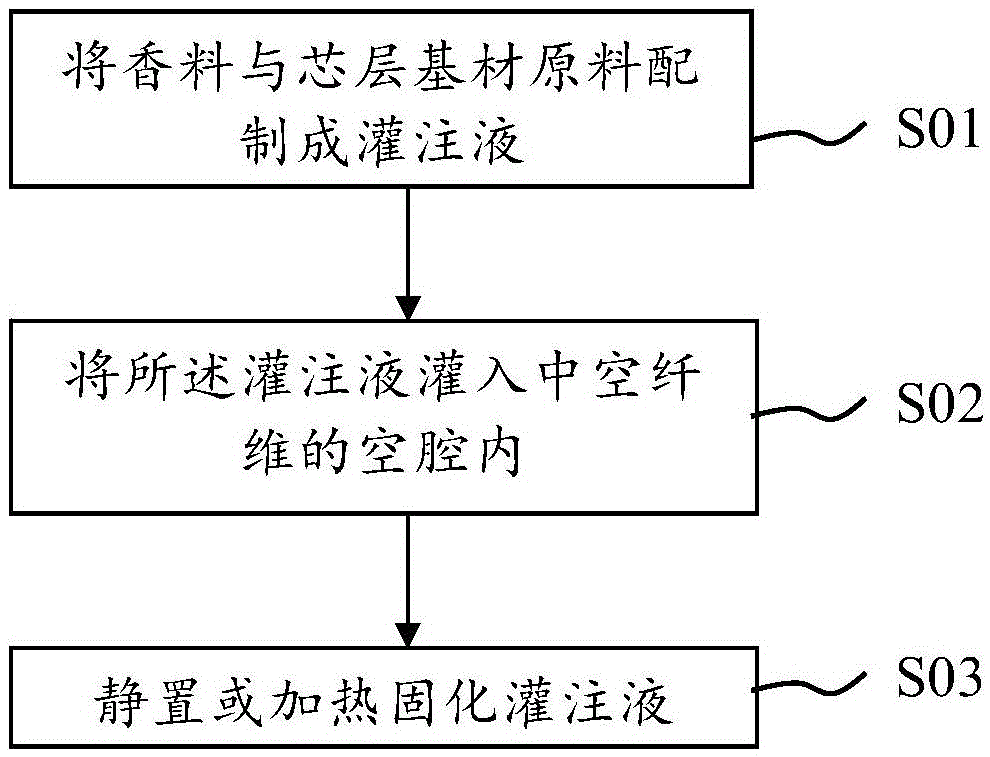

[0043] On the other hand, the embodiment of the present invention also provides a preparation method of the fragrance composite fiber of the embodiment of the present invention described above. In one embodiment, in conjunction with the figure 1 , the process flow of the preparation method of the spice composite fiber in the embodiment of the present invention is as follows figure 2 shown, it includes the following steps:

[0044] Step S01: preparing the fragrance and the core layer base material into a perfusion solution;

[0045] Step S02: pouring the perfusate into the cavity of the hollow fiber 1;

[0046] Step S03. Standing or heating to solidify the perfusion solution: place the perfused hollow fibers at room temperature or heat treatment below 80° C., so that the perfusion solution poured into the hollow fiber cavities is cured to form the core layer 2 .

[0047] Wherein, the fragrance described in the above-mentioned step S01 is the fragrance contained in the fragr...

Embodiment 1

[0059] The present embodiment 1 provides a lavender oil composite fiber, which has a skin-core structure, and its structure is such as figure 1 , comprising a hollow fiber as a skin layer and a core layer formed of lavender oil and auxiliary materials in the hollow fiber cavity. The fiber has aromatherapy health benefits.

[0060] The technological process of the preparation method of the lavender oil composite fiber refers to figure 2 shown, including the following steps:

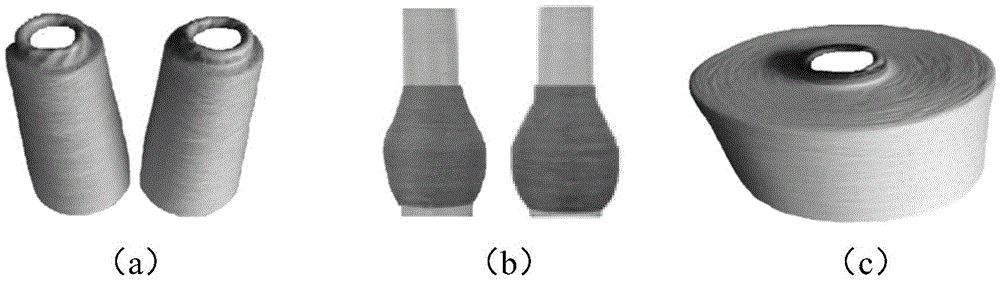

[0061] Step S11. Obtaining hollow fibers: take polyester filaments with a hollow ratio of 25%, a specification of 75D / 36F, and no through-holes in the walls, cut them into 60 5m-long segments and combine them into tows, and seal the two tows with sealant. The part with a length of about 10cm at the end is respectively enclosed in two containers with a volume of about 50ml and a height of about 10cm, so that the end of the tow just touches the bottom surface of the container;

[0062] Step S12. Preparin...

Embodiment 2

[0068] This embodiment 2 provides a clove oil and chamomile oil composite fiber, which has a skin-core structure, including a hollow fiber as a skin layer and a core layer formed of clove oil and chamomile oil and auxiliary materials in the hollow fiber cavity . The fiber has aromatherapy, antibacterial, and anti-eczema properties.

[0069] The process flow of the fiber preparation method refers to figure 2 shown, including the following steps:

[0070] Step S21: refer to Step S11 of Example 1, except that the hollow fibers used are polyester filaments with a hollow ratio of 35%, a specification of 100D / 24F, and no through-holes in the wall;

[0071] Step S22: Mix 20ml of clove oil and 4ml of chamomile oil, add 0.2g of pentaerythritol to fully mix, then add 0.8ml of 1,2-propanediol to mix, and keep the temperature of 20°C to prepare a mixture of fragrance and polyol for later use;

[0072] Step S23: Mix 4.5 ml of isophorone diisocyanate and 0.5 ml of toluene diisocyanate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com