Nitride bottom layer, light emitting diode and bottom layer preparation method

A technology of light-emitting diodes and nitrides, which is applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of reducing the quality of light output efficiency of semiconductor components and devices, increasing stress, etc., so as to improve luminous efficiency and reduce crystallinity. lattice difference, the effect of reducing the surface energy state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

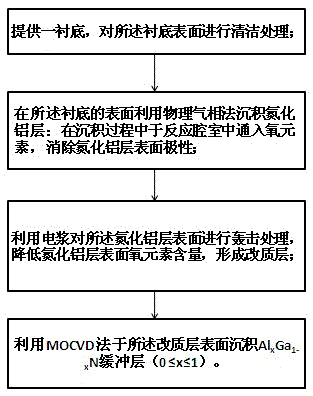

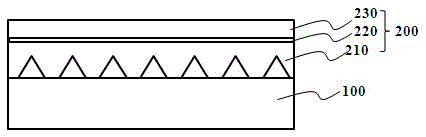

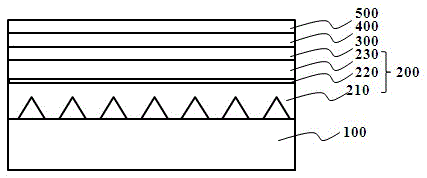

[0027] see Figure 1~2 , the nitride bottom layer, light emitting diode and bottom layer preparation method implemented in the present invention will be described in detail below.

[0028] Firstly, a substrate 100 is provided. The selection of the substrate 100 includes but not limited to sapphire, aluminum nitride, gallium nitride, silicon, and silicon carbide, and its surface structure can be a planar structure or a patterned structure. In this embodiment, a sapphire patterned substrate is used.

[0029] Next, put the substrate 100 into the PVD chamber and clean the surface of the substrate, adjust the temperature of the chamber to 20-200°C or 200-1100°C, the pressure to 2-10mtorr, and use the PVD method to deposit a thickness of 25-500 The aluminum nitride layer 210 of angstroms is fed with oxygen during the deposition process, so that the deposited aluminum nitride layer 210 contains a concentration of 1×10 20 ~9×10 23 cm -3 of oxygen elements. Since the natural cryst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com