Separated heat radiation type novel motor based on heat pipe

A heat dissipation and heat pipe technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of no separation of cooling channels and motors, complex processing of motor casings, and reduced power density ratio, etc., to improve heat conduction efficiency, Compact structure and improved weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below.

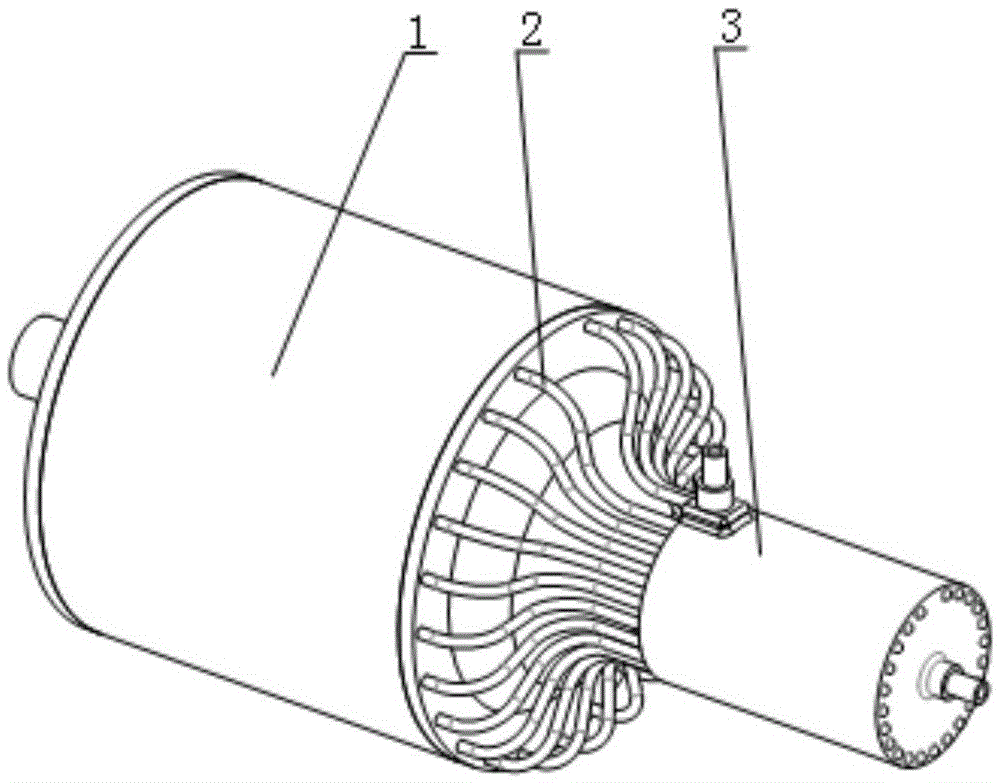

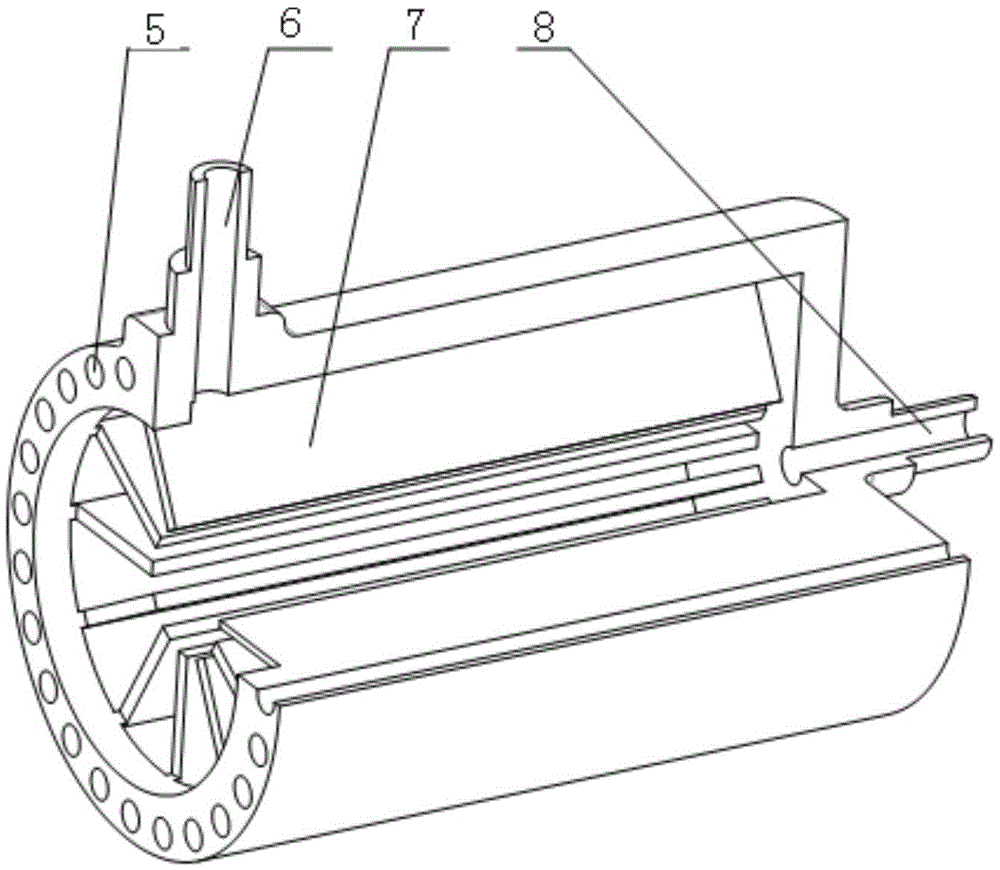

[0031] A heat pipe-based novel motor with separated heat dissipation includes a motor core, a motor case, a water-cooling circulation system, and a heat pipe.

[0032] The motor core is a permanent magnet drive motor.

[0033] The motor casing is cylindrical and tightly wrapped around the motor core. The motor casing is made of aluminum alloy. The groove inside (inside the wall) is cast or removed. The groove is processed into a round groove or a square groove to adapt to a cylindrical heat pipe or a flat heat pipe.

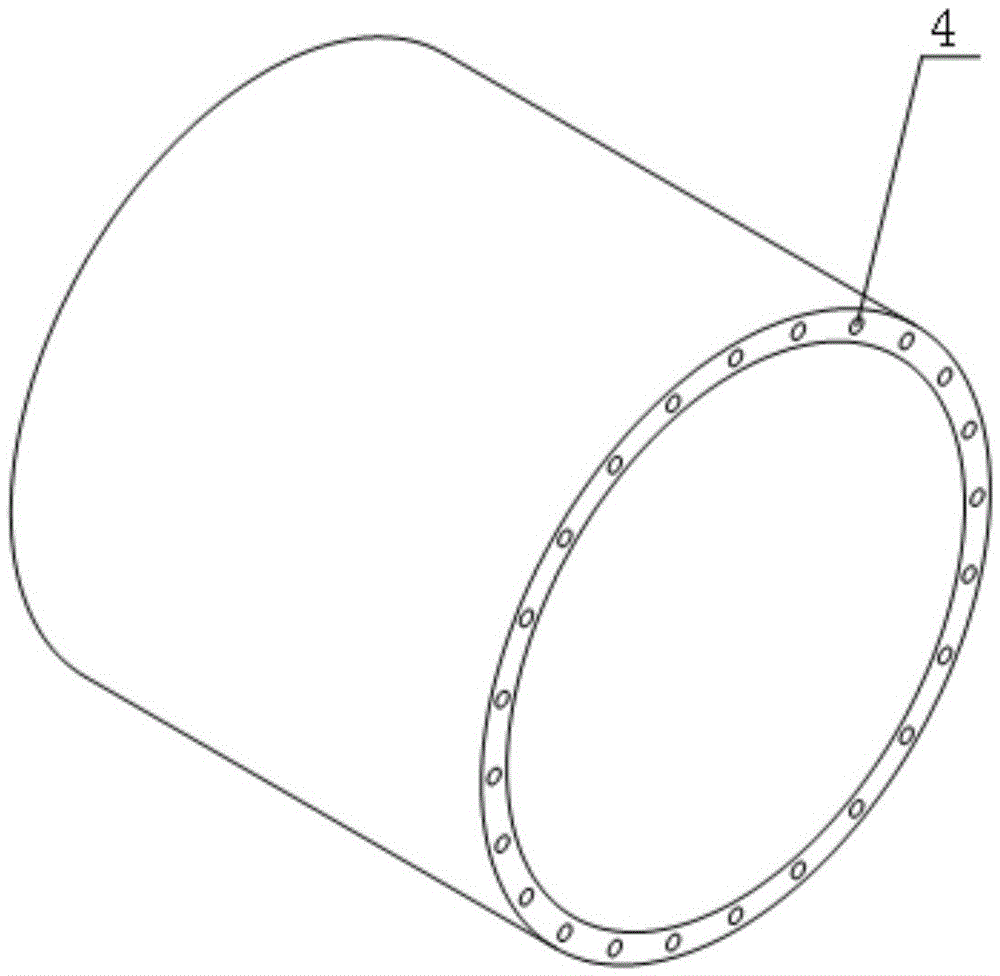

[0034] The water-cooling circulation system includes a shell, which is provided with a water inlet and a water outlet, and a mounting groove is arranged in the wall of the shell; one end of the heat pipe is inserted into the bar-shaped mounting groove, and is tightly connected with the shell through an expansion process. The outer shell is surrounded by a water tank. The outer shell is ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com