Load driving device with wide voltage input

A technology of load drive and voltage, which is applied in the direction of lighting devices, lamp circuit layout, electric light source, etc., can solve the problems of increased procurement costs and inconvenient material inventory management, and achieve simple material inventory management, convenient product mass production, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings. Where possible, elements / members using the same reference numerals in the drawings and embodiments represent the same or similar parts.

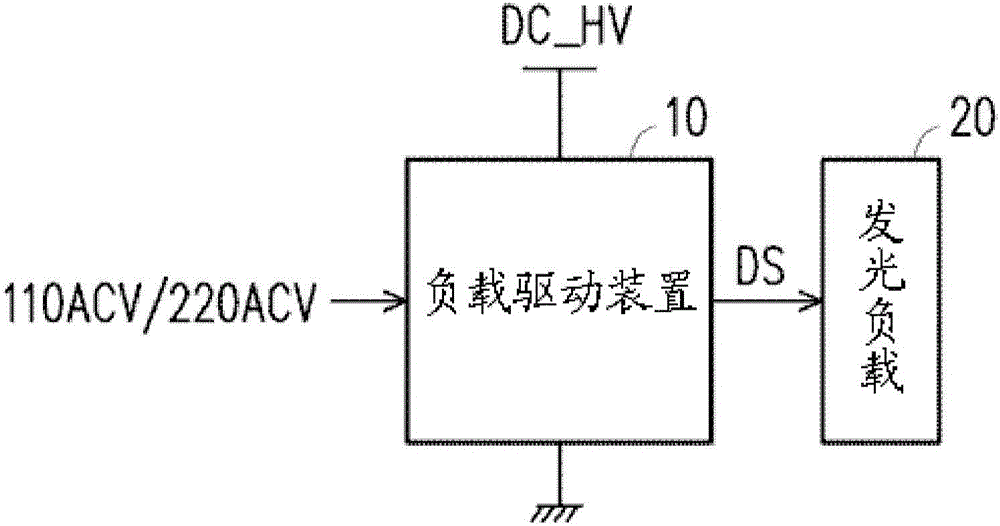

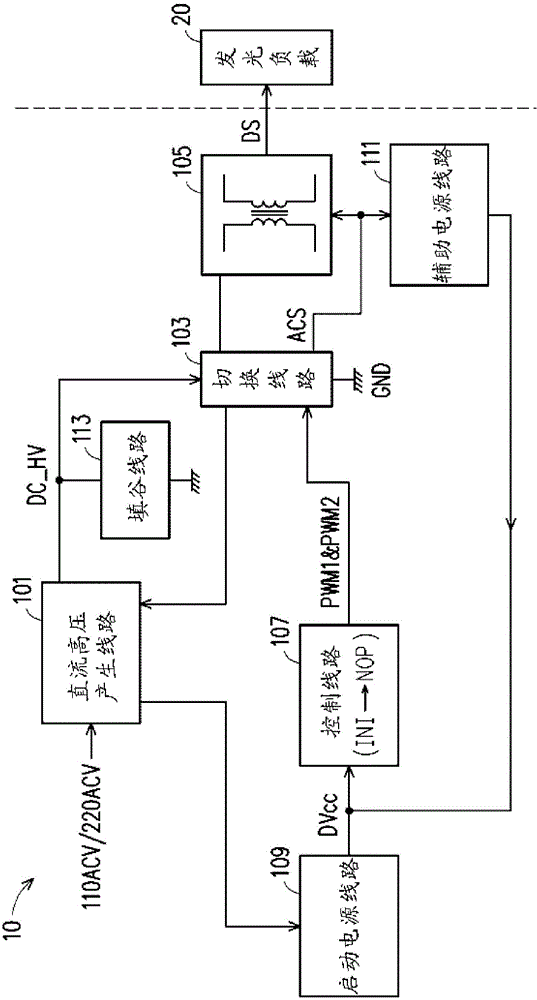

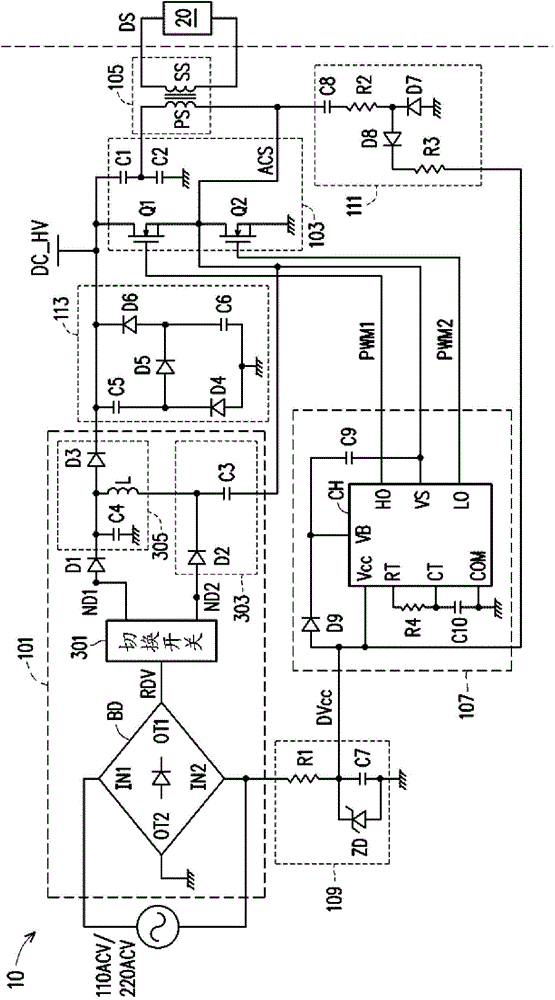

[0052] figure 1 It is a system architecture diagram of the load driving device 10 according to an exemplary embodiment of the present invention. figure 2 for figure 1 A block diagram of the load driving device 10. image 3 for figure 2 The implementation circuit diagram of the load driving device 10. Please refer to Figure 1 ~ Figure 3 The load driving device 10 is suitable for providing a driving signal DS to drive any type of luminous load 20, for example: any resistive or capacitive luminous load (which may be but not limited to an AC light-emitting diode load or a lamp load). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com