A Flexible Approach to Enhance Steam Cracker and Platinum Reforming Feeds

A technology for hydrocarbon feed streams and materials, which can be used in cracking, non-catalytic thermal cracking, and multi-stage parallel cracking process treatment, etc., and can solve the problems of limited availability of petroleum sources, high cost, and increased cost of light olefins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

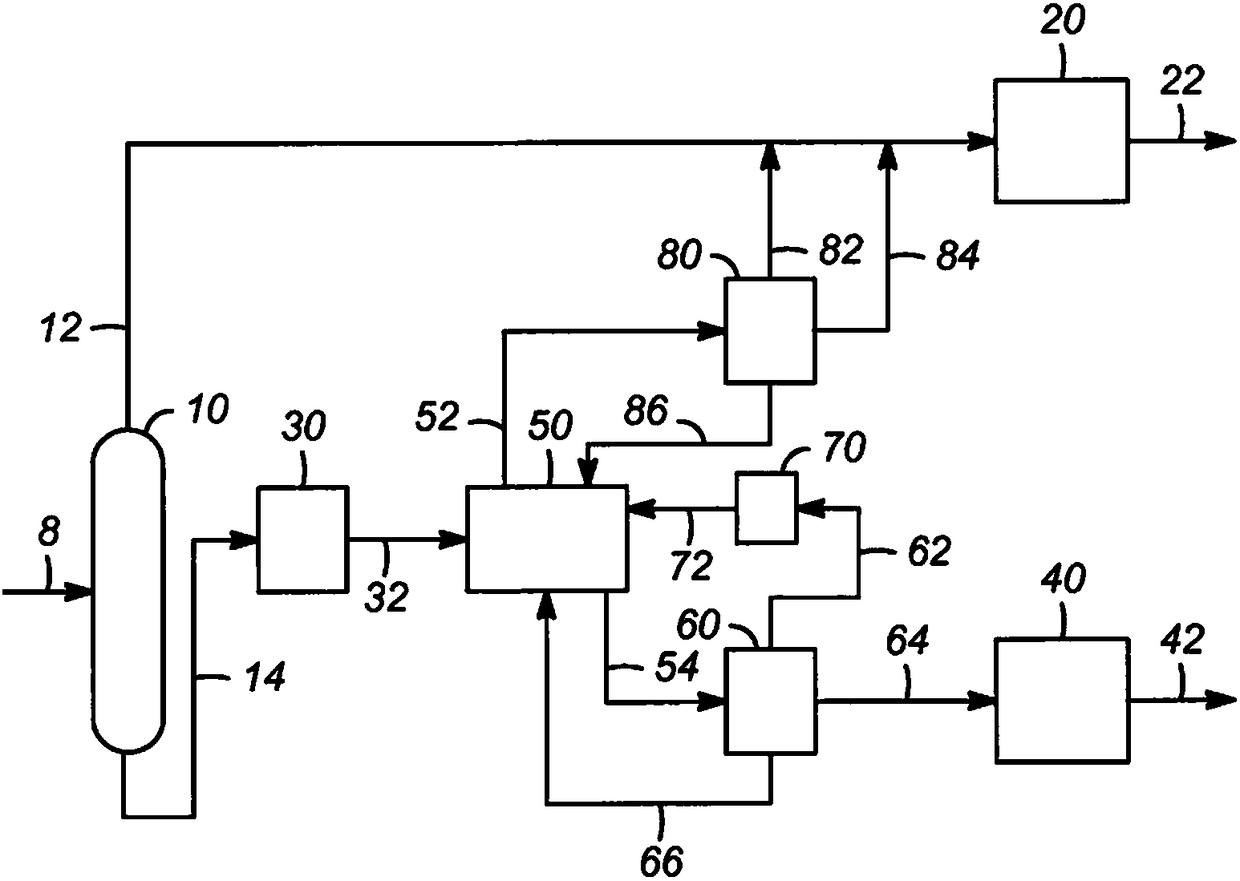

[0018] The present invention provides a method for increasing the yield or conversion of light olefins to increase the hydrocarbon component from a hydrocarbon feed to a gasoline blending cell. The process includes separating a naphtha feedstock into a first stream or cracker unit feed stream component that is more easily processed in a cracking unit and a second stream or reformer that is more easily processed in a reforming unit Unit feed stream components. The process includes the ability to convert components from a cracked stream to a reformed stream and convert components from a reformed stream to a cracked stream.

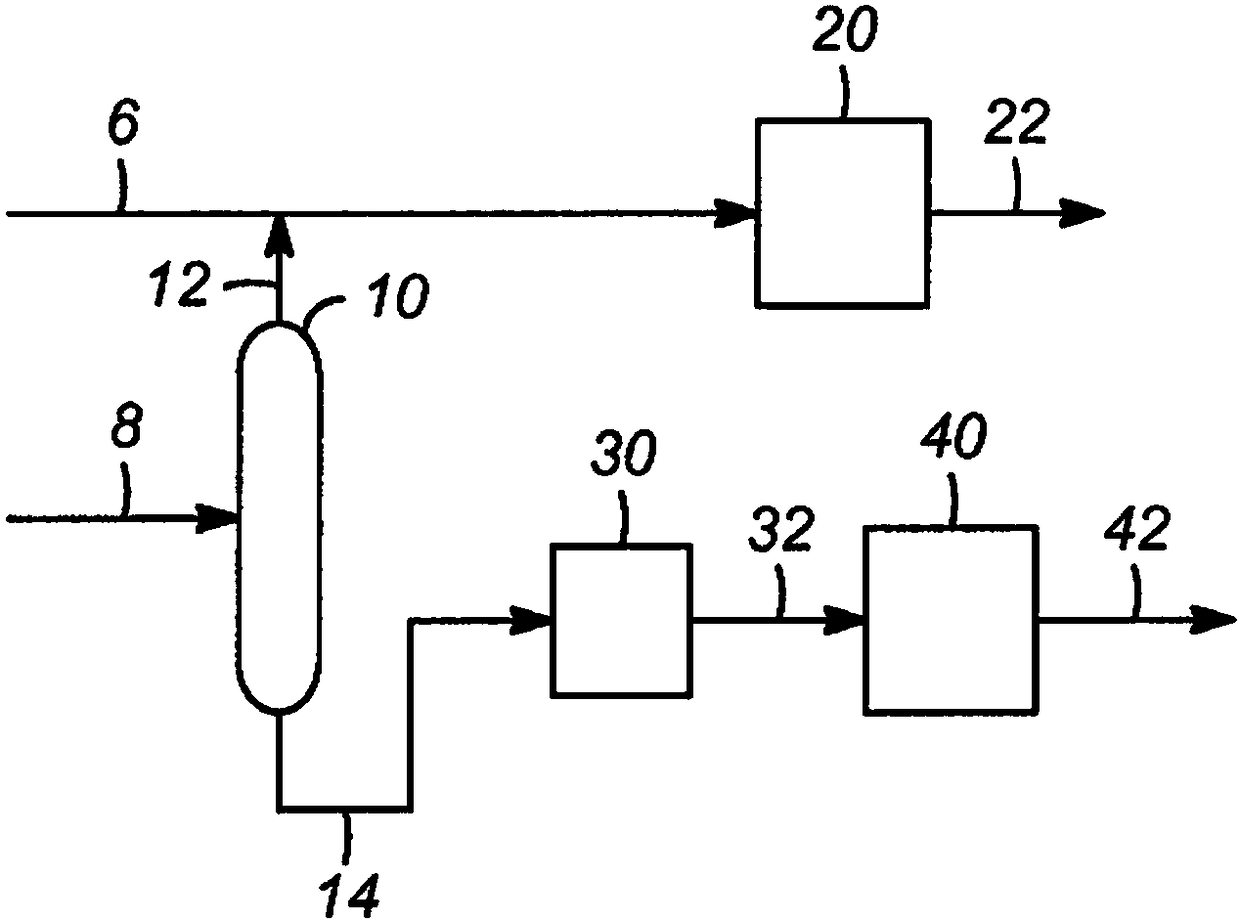

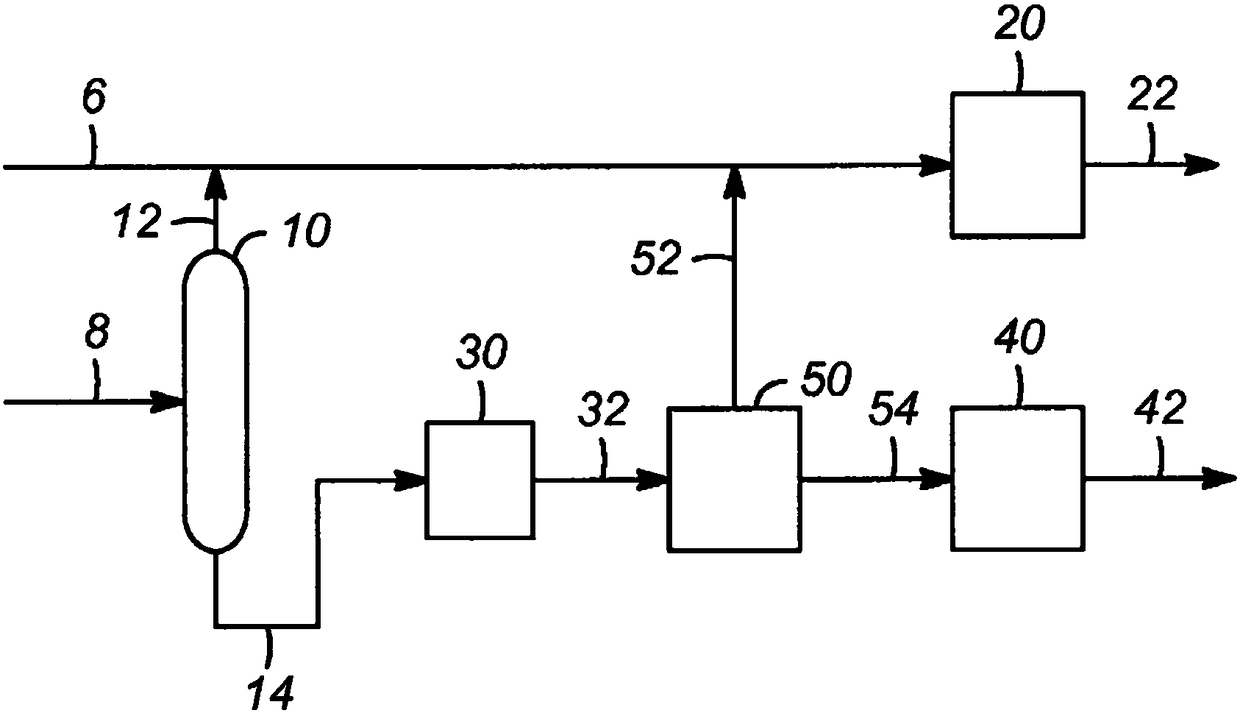

[0019] Processing of the naphtha feedstream can be used to produce light olefins and provide hydrocarbon components to gasoline blending pools or reforming components to produce aromatics to be sent to the aromatics complex. Such as figure 1 The basic process shown in includes splitting the naphtha feed stream into two parts, a second part 6 and a first pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com