Connections for friction clutches and torsional vibration dampers

A friction clutch and torsional vibration technology, applied in clutches, fluid-driven clutches, mechanical-driven clutches, etc., can solve the problems of structural failure, noise, and reduce the unevenness of internal combustion engine rotation, and achieve improved vibration reduction and small axial installation effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

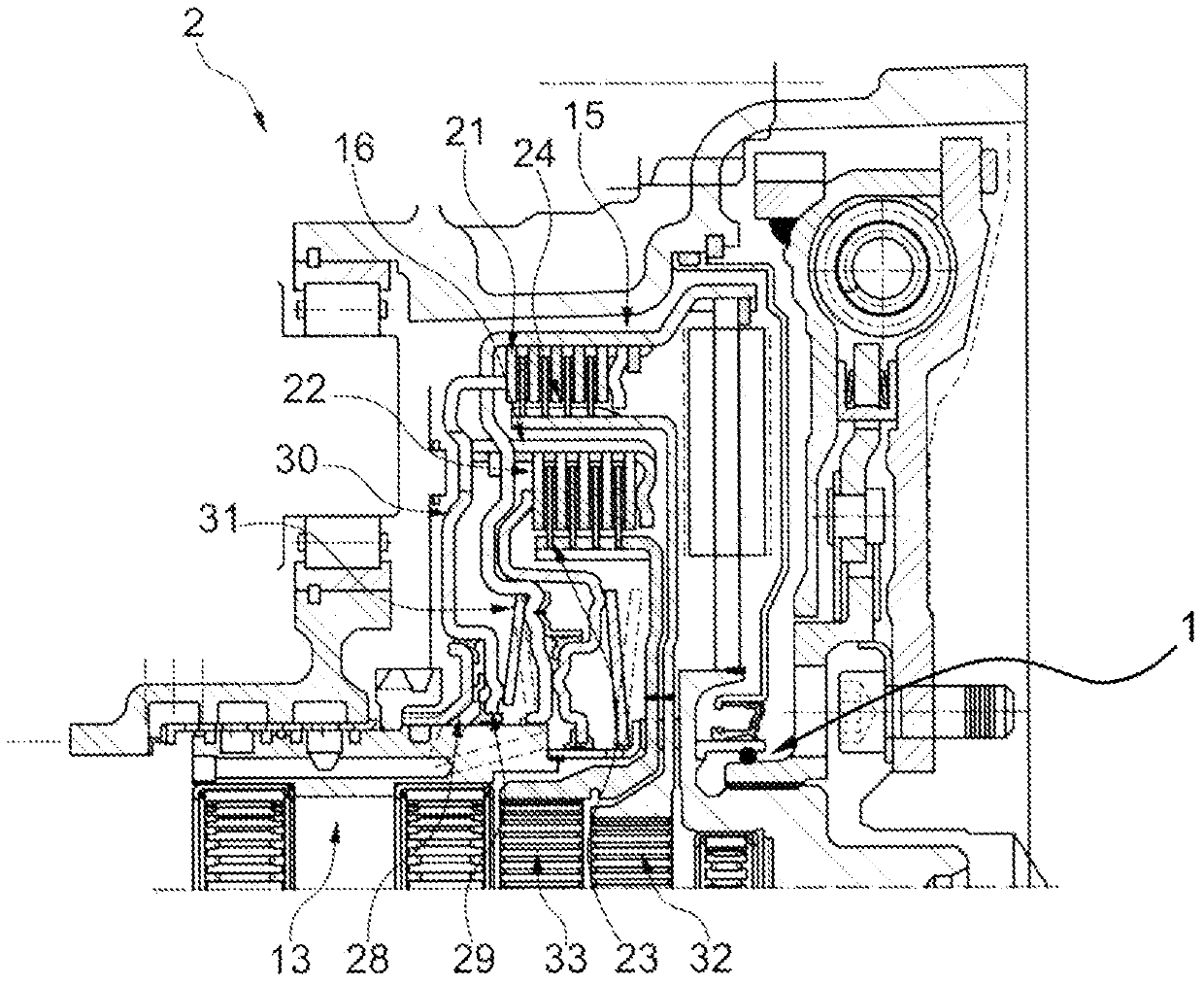

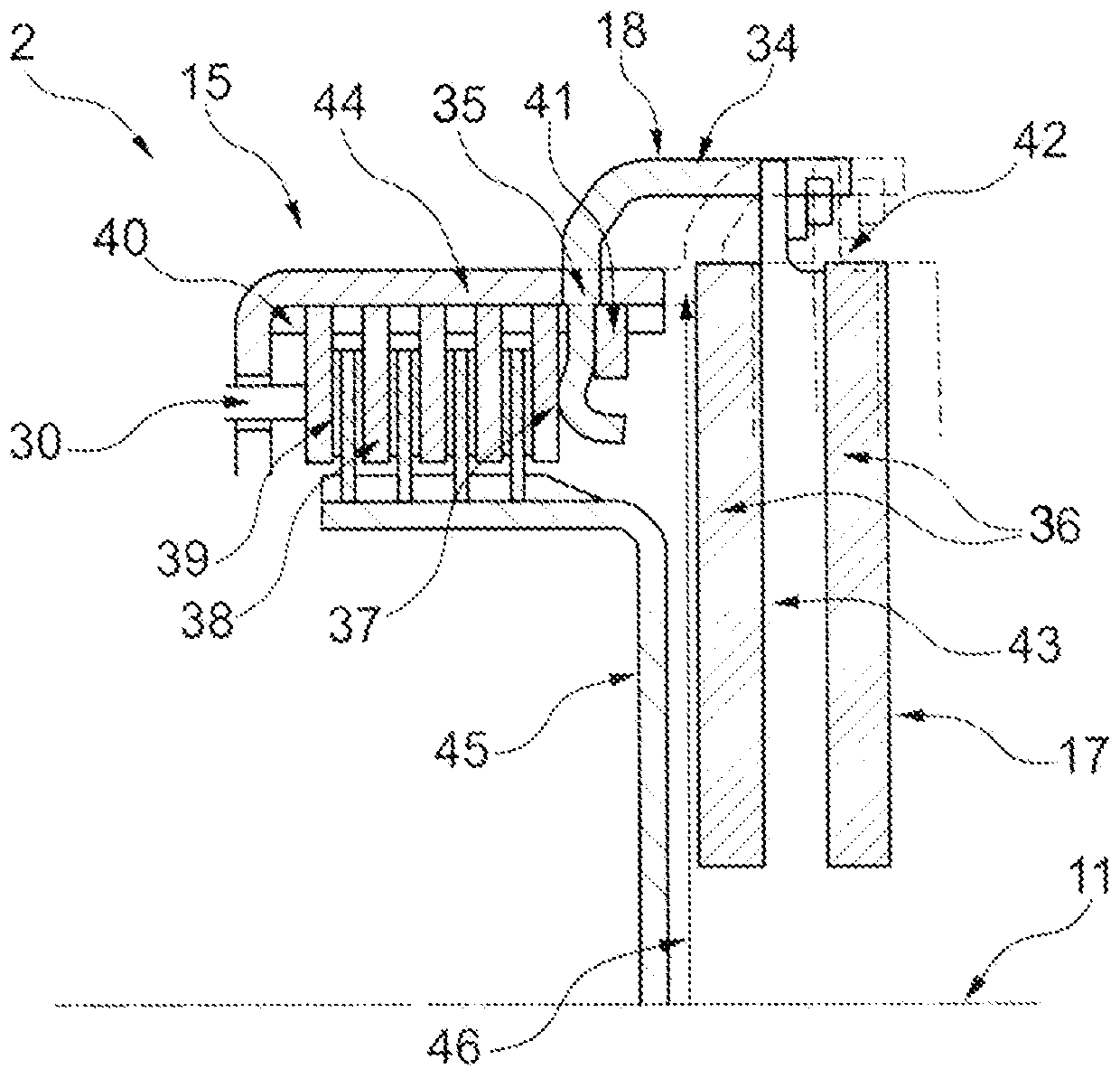

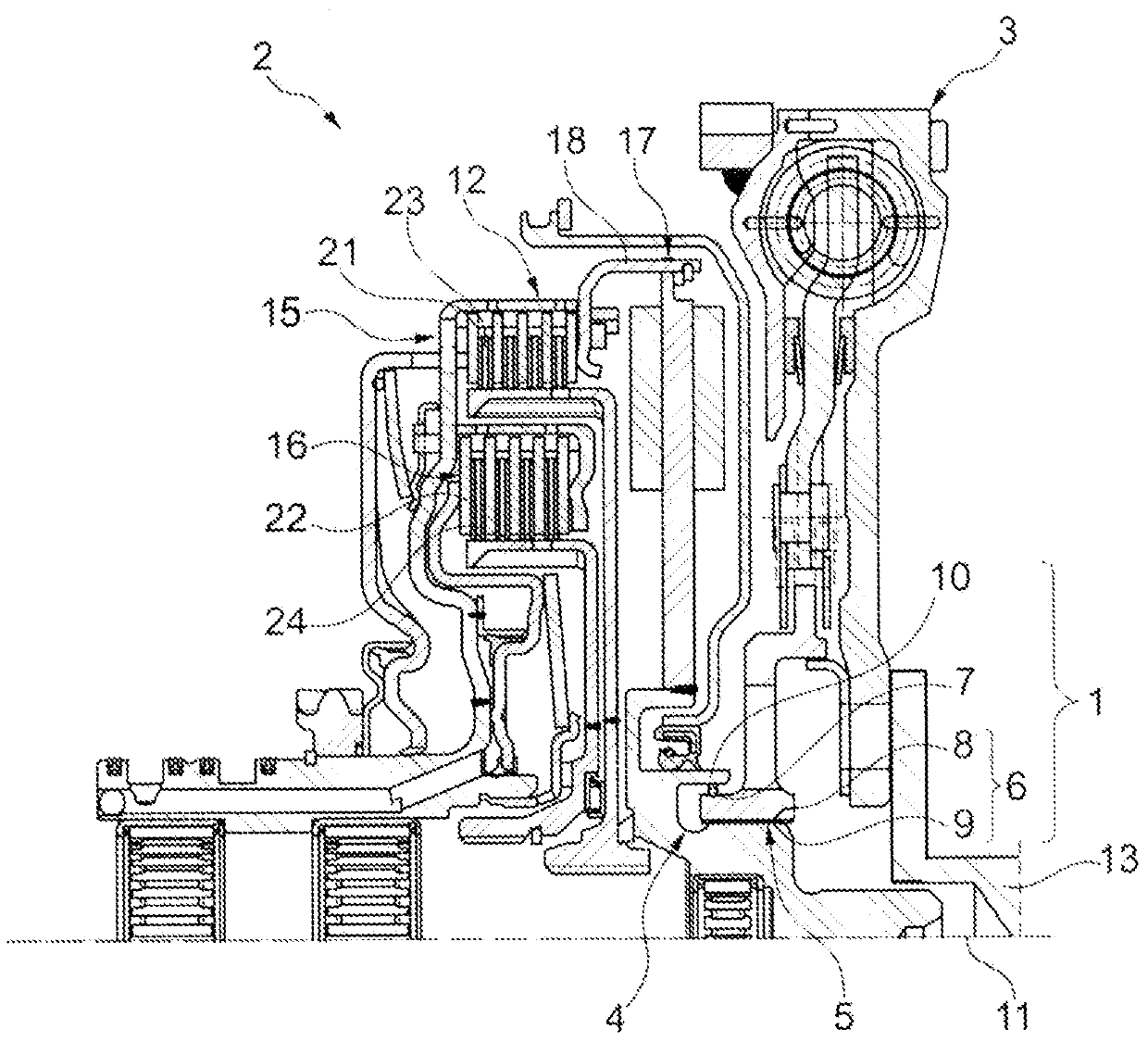

[0042] figure 1 A friction clutch 2 is shown, in which a first friction set 15 and a second friction set 16 are arranged. The first friction group 15 here comprises a first pressure plate 21 and a first friction disc 23, while the second friction group 16 comprises a second pressure plate 22 and a second friction disc 24, which can respectively form a friction locking contact with each other. , so that the torque in the friction sets 15 and 16 is switchably transmitted. In this exemplary embodiment, the friction groups 15 and 16 are actuated, for example, by means of a pressure chamber 28 , which acts on the actuation device 30 in such a way that one friction group 15 or 16 in each case is compressed. The return spring 31 here generates the counterforce required to release the friction set 15 or 16 . The torque transmitted from the driven shaft 13 can be transmitted to the first output shaft 32 or the second output shaft 33 through the friction sets 15 and 16 . Furthermore,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com