Wet dust remover

A wet dust collector and housing technology, applied in the field of dust removal equipment, can solve the problems of poor dust and water droplet aggregation effect, affecting the stability of the dust collector, and blocked rotation of the rotating shaft, so as to improve efficiency and dust removal effect, improve dust removal effect, The effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

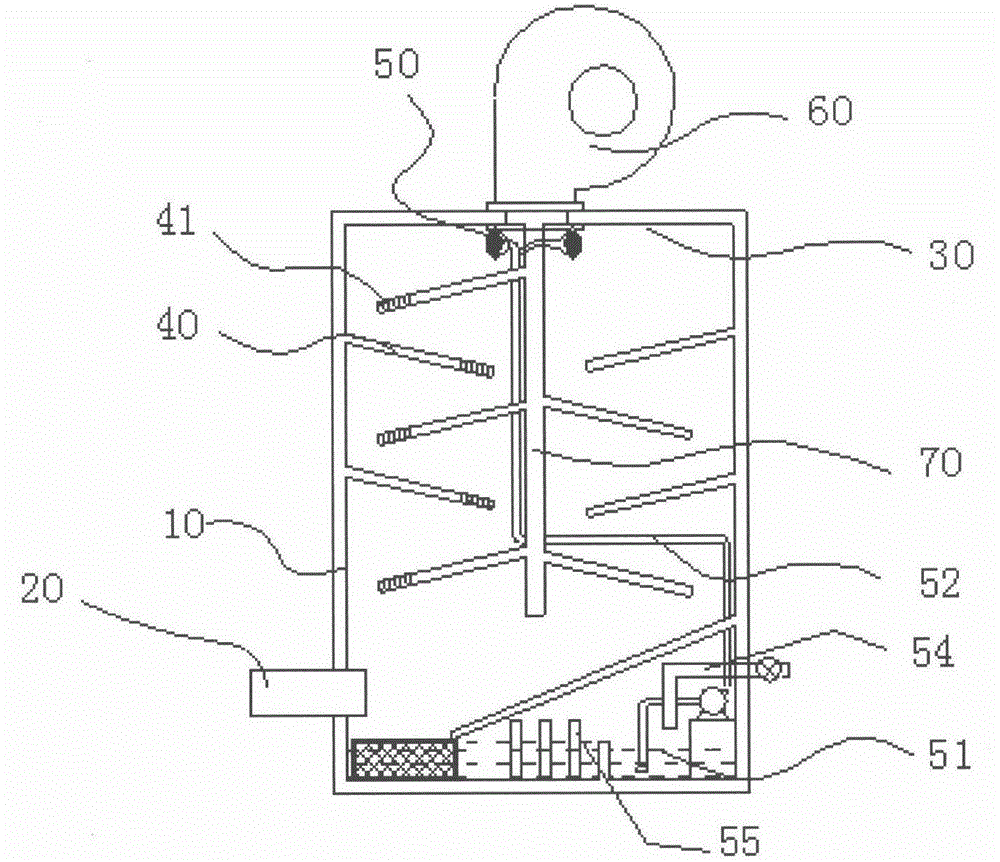

[0015] The wet dust collector disclosed in the present invention includes a hollow cylindrical shell 10, an air inlet 20, a partition 40 inclined downward, an air outlet 30, a sedimentation tank, a reservoir 51, and a water inlet pipe connected to the reservoir 51 54. The diversion plate and the spray assembly, the sedimentation tank and the reservoir 51 are respectively arranged on both sides of the housing 10, the diversion plate is inclined downward from the top of the reservoir 51 to the direction of the sedimentation tank, and the spray assembly includes a nozzle 50, a water pump As well as the duct 52, the air inlet 20 is arranged on the lower side wall of the housing 10 and the centerline of the air inlet 20 is along the tangential direction of the housing 10, and a number of guide flow holes are also opened on the partition 40, and the air outlet 30 is arranged on the housing 10. The top and the center line of the air outlet 30 coincide with the axial direction of the c...

Embodiment 2

[0017] The wet dust collector disclosed in the present invention includes a hollow cylindrical shell 10, an air inlet 20, a partition 40 inclined downward, an air outlet 30, a sedimentation tank, a reservoir 51, and a water inlet pipe connected to the reservoir 51 54. The diversion plate is provided with a baffle plate 70 with a through hole and a spray assembly. The baffle plate 70 is vertically arranged in the housing 10, and the sedimentation tank and the water storage tank 51 are respectively arranged on both sides of the housing 10. The drainage plate Inclined downward from the top of the reservoir 51 towards the sedimentation tank, the spray assembly includes a nozzle 50, a water pump and a conduit 52, the air inlet 20 is arranged on the lower side wall of the housing 10 and the centerline of the air inlet 20 is along the tangential direction of the housing 10, A plurality of guide holes are also opened on the partition 40 , the air outlet 30 is arranged on the top of the...

Embodiment 3

[0019] The wet dust collector disclosed in the present invention includes a hollow cylindrical shell 10, an air inlet 20, a partition 40 inclined downward, an air outlet 30, a sedimentation tank, a reservoir 51, and a water inlet pipe connected to the reservoir 51 54. A diversion plate, an exhaust fan 60, a baffle plate 70 with a through hole and a spray assembly, the baffle plate 70 is vertically arranged in the housing 10, and the sedimentation tank and the water storage tank 51 are respectively arranged on two sides in the housing 10. side, the diversion plate is inclined downward from the top of the reservoir 51 to the direction of the sedimentation tank, the spray assembly includes a nozzle 50, a water pump and a conduit 52, the air inlet 20 is arranged on the lower side wall of the housing 10 and the centerline of the air inlet 20 is along the In the tangential direction of 10, a number of guiding holes are opened on the partition 40. The air outlet 30 is arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com