Novel sorting equipment

A sorting and new type of technology, applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc. Production efficiency and other issues, to achieve the effect of simple structure, few components, and good shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0038] The present invention will be described in detail below with reference to the accompanying drawings and examples.

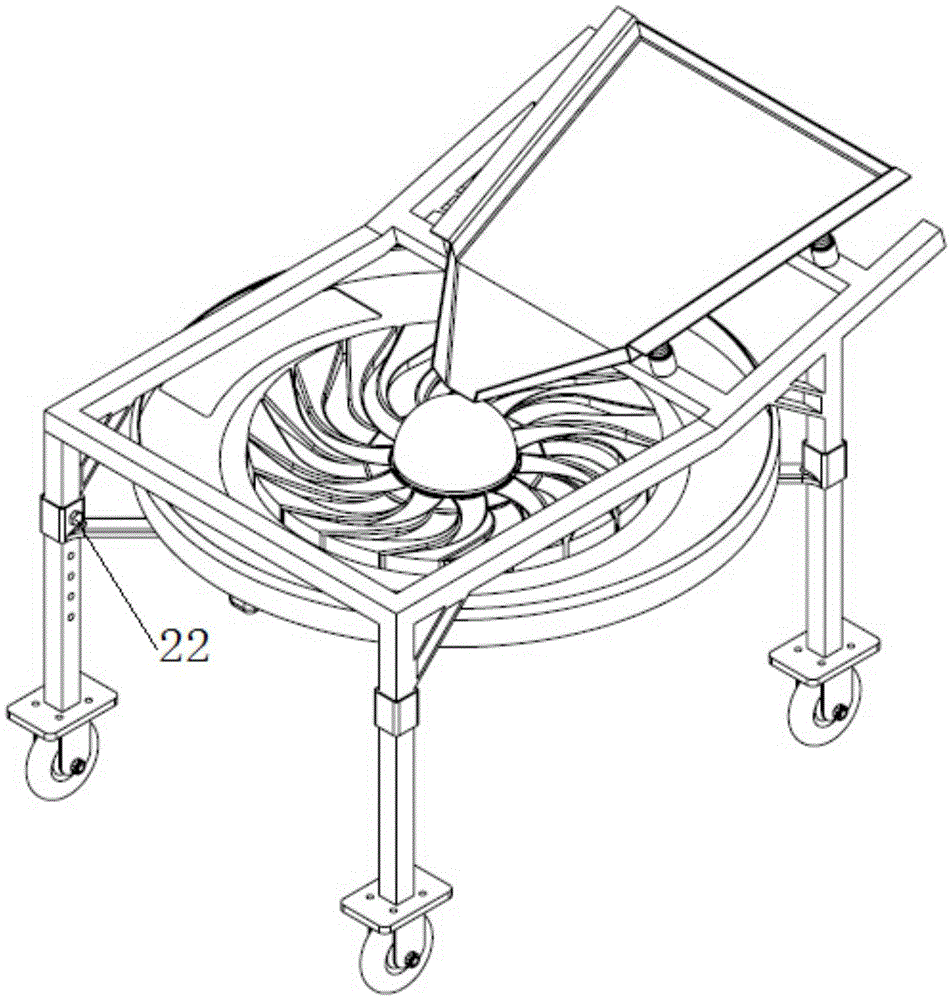

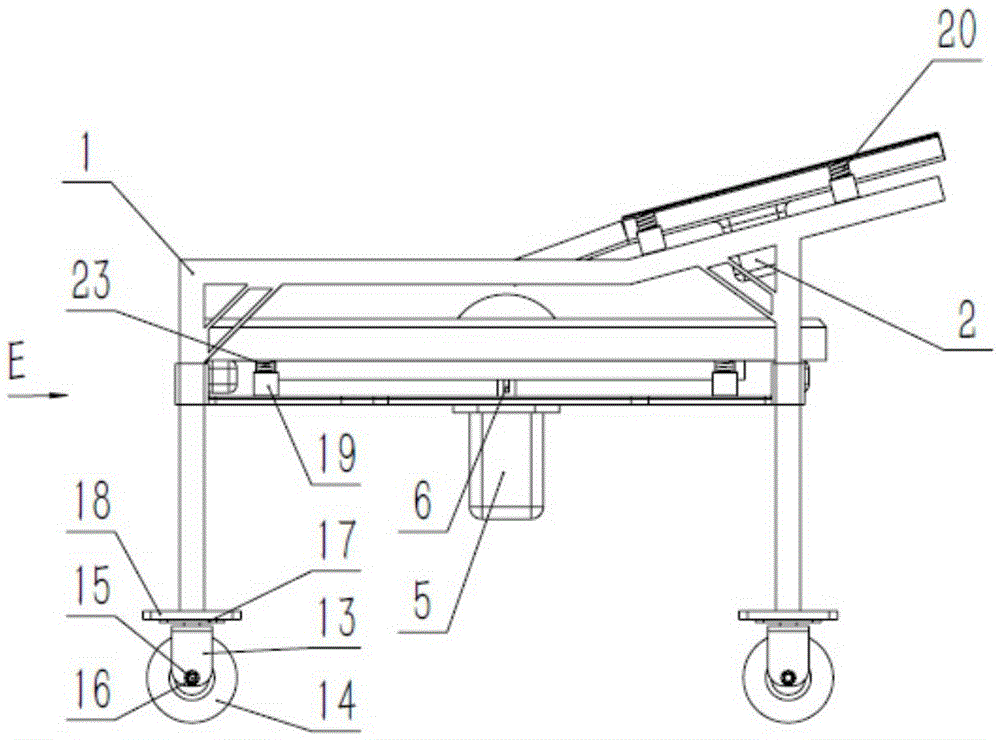

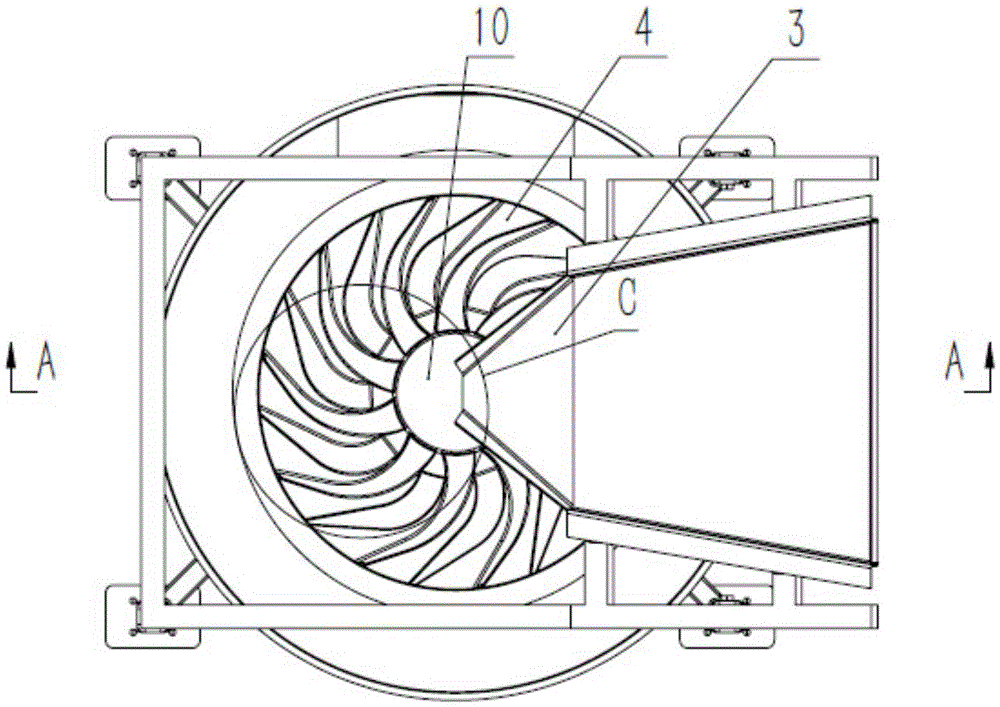

[0039] like Figure 1-12 As shown, a new type of sorting equipment includes a frame-type support 1, a hopper 3 is erected on the frame-type support 1, an elastic member is provided between the hopper 3 and the support 1, and a There is a hopper 3 vibration source that drives its vibration, and a material selection plate 4 is arranged below the outlet of the hopper 3, and the middle part of the material selection plate 4 is facing the discharge port of the hopper 3, and the middle part of the material selection plate 4 is below the outlet. A rotating power source is provided, and the material selection disc 4 is evenly provided with some guide grooves from the middle to the surroundings,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com