Electric linear feeding unit and assembling method thereof

A linear feed, electric technology, used in assembly machines, feeding devices, metal processing equipment, etc., can solve the problems of reducing the working accuracy of the equipment, large rotational inertia force of the lead screw, vibration and noise of the lead screw, etc., to improve the transmission efficiency. , The effect of increasing the rotational speed of the drive nut and reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing of description and specific embodiment:

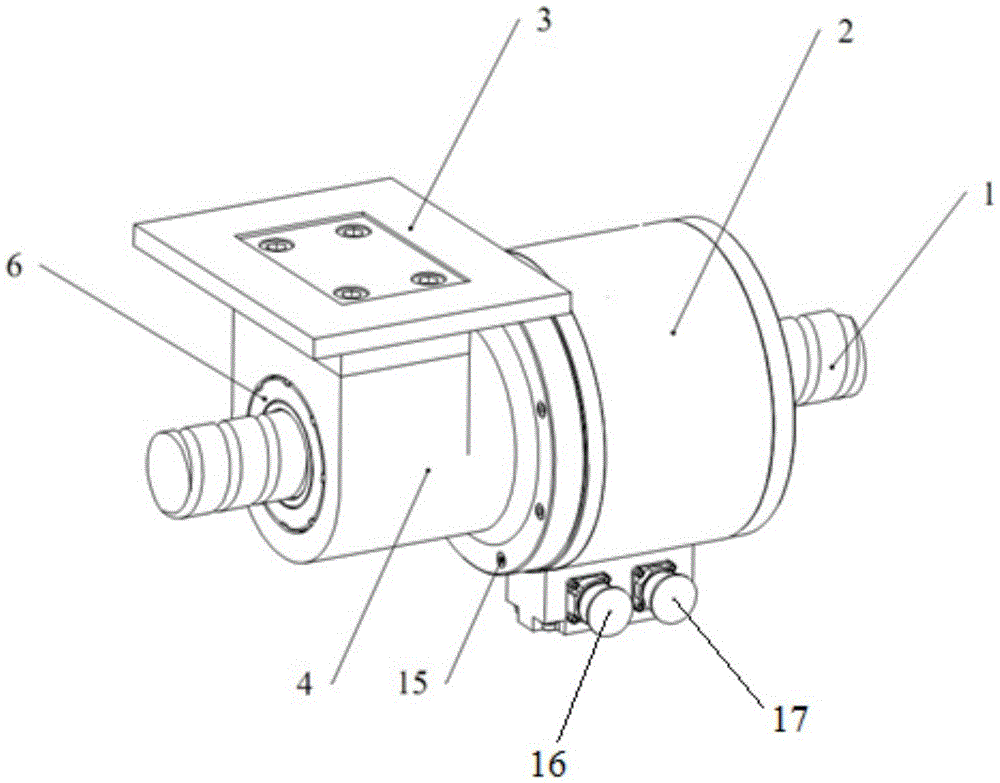

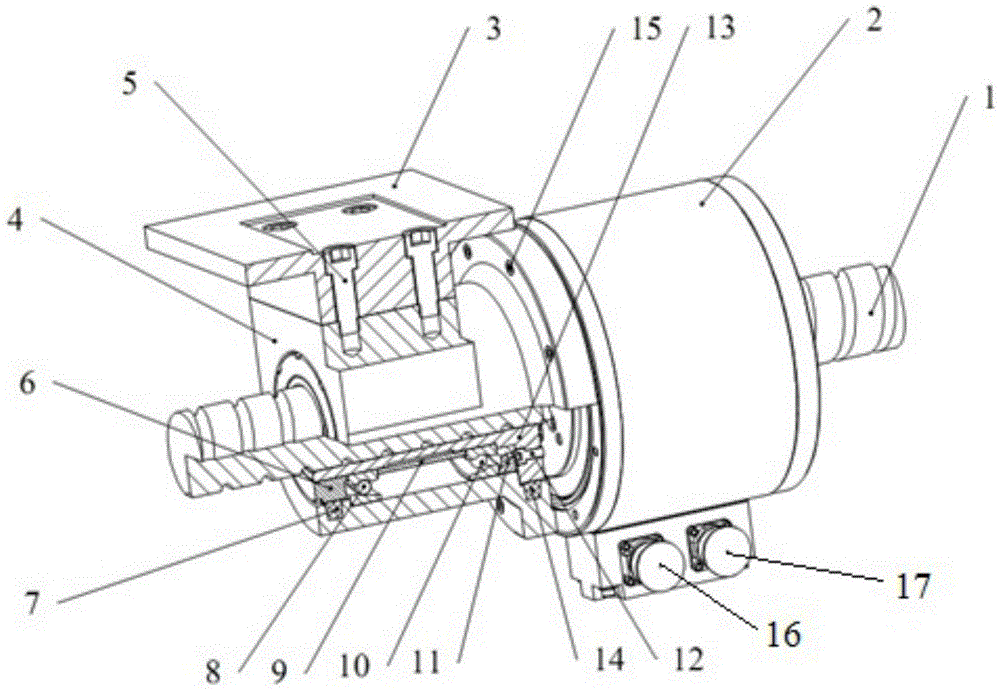

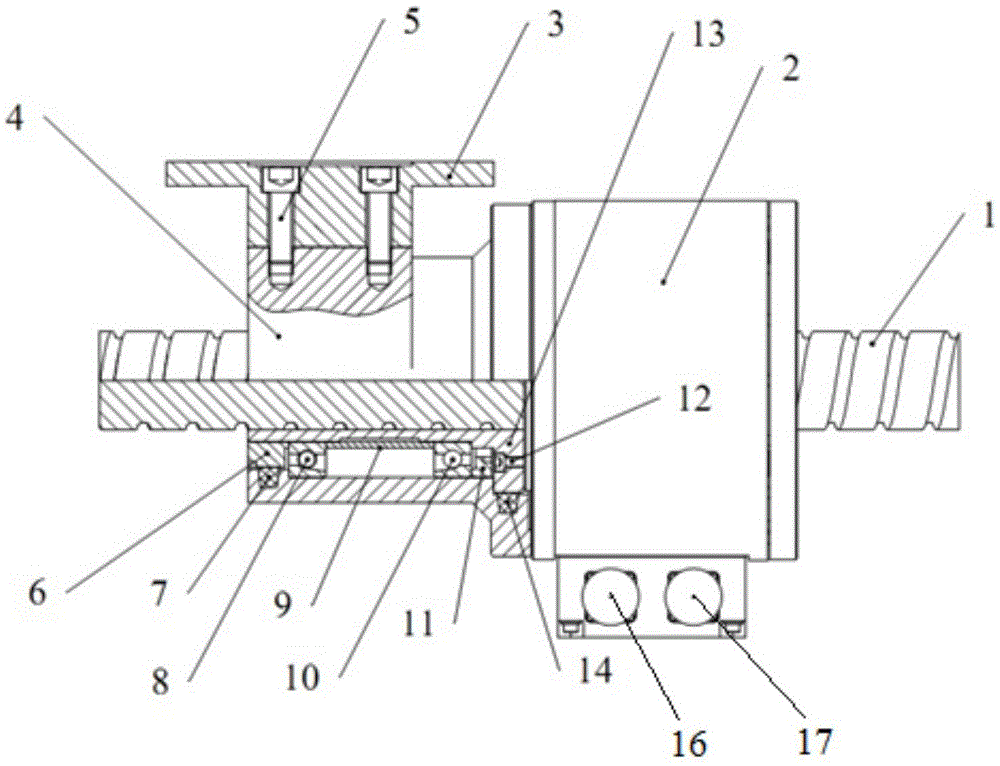

[0031] Such as figure 1 , figure 2 and image 3 As shown, an electric linear feed unit, its structure includes: lead screw 1, frameless motor 2, supporting plate 3, nut sleeve 4, first fastening screw 5, left bearing end cover 6, left felt ring 7, Left bearing 8, sleeve 9, right bearing 10, right bearing end cover 11, second fastening screw 12, drive nut 13, right felt ring 14, third fastening screw 15, etc.

[0032] The frameless motor 2 is a hollow shaft brushless motor, which is composed of a hollow rotor, a stator and a phase sequence controller. The hollow rotor is in the shape of a sleeve, the outer surface of the hollow rotor is evenly distributed with magnetic steel bars, and there is a proper gap between the inner surface of the hollow rotor and the ball screw.

[0033] Such as Figure 5 As shown, the driving nut 13 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com