Electric grinding device

一种磨削、电动的技术,应用在电动组件、磨削/抛光设备、磨床等方向,能够解决小孩子难自己操作等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The first embodiment provides an electric grinder for cleaning the body surface of a living body.

[0043] The organisms referred to here include human body and animals, and the human body will be used as an object for description below.

[0044] The electric sonic cleansing hair brush includes a swing motor and a grinding head, the swing motor can output a reciprocating swing motion, and the grinding head swings driven by the swing motor.

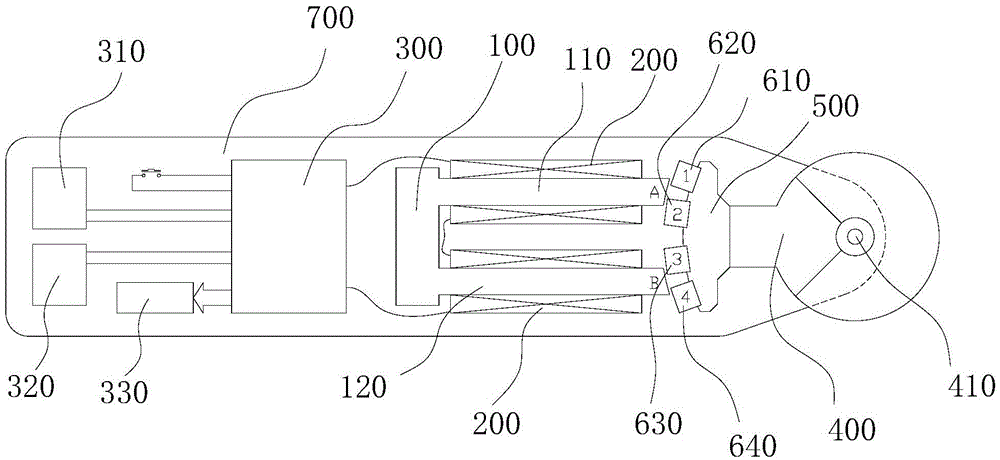

[0045] Please refer to figure 1 , 2 , 3, 4, 5, the swing motor includes:

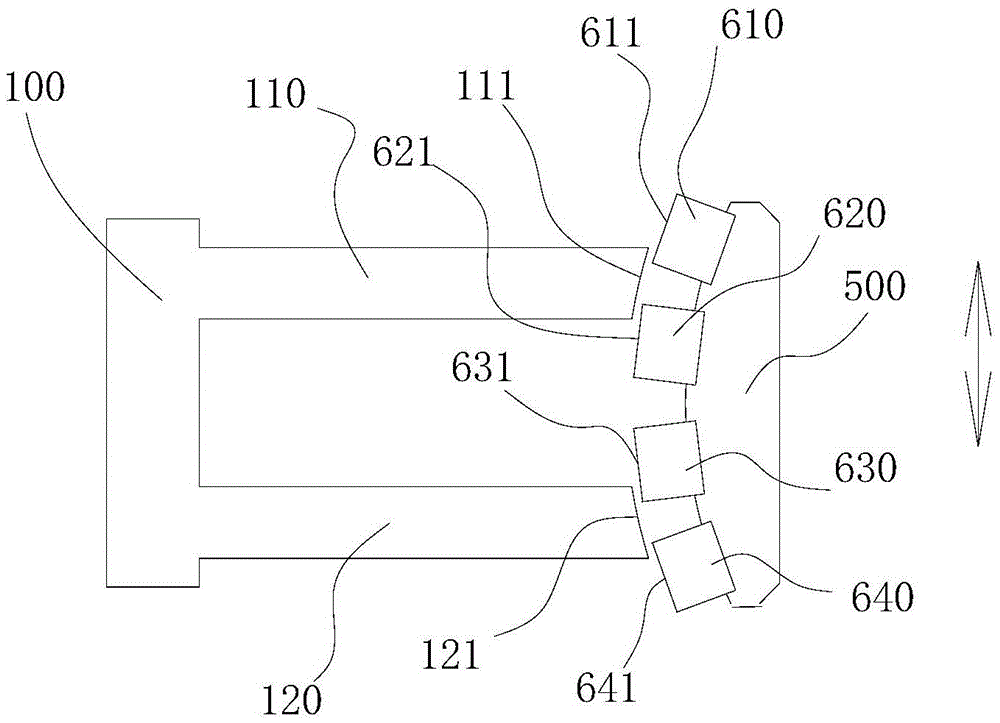

[0046] A U-shaped yoke 100, the U-shaped yoke 100 has a first leg 110 and a second leg 120, coils 200 are respectively wound on the first leg 110 and the second leg 120;

[0047] A control circuit 300, the control circuit 300 is electrically connected to the coil 200, and generates alternating pulses, so that the end faces 111 and 121 of the two legs of the U-shaped magnetic yoke 100 generate alternating magnetic poles;

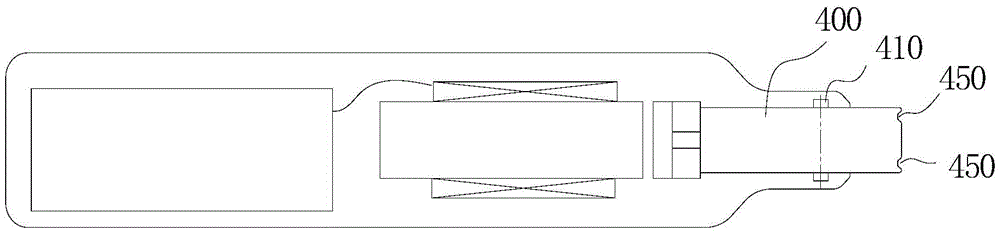

[0048]A swing arm 400 that can sw...

Embodiment 2

[0081] Embodiment 2 provides another swing motor.

[0082] Please refer to Figure 13 , the swing motor is improved on the structure shown in the first embodiment, and a resonant elastic member for generating resonance at a constant swing frequency is added.

[0083] Specifically, one end of the resonant elastic member is fixed on the fulcrum of the swing arm, and the other end is connected to the outer arm or the inner arm.

[0084] further, Figure 13 The resonant elastic member shown in is a straight spring steel wire, in addition, other shapes of elastic members can also be used instead, such as Figure 14 The middle portion of the resonant elastic member shown is curved.

Embodiment 3

[0086] The third embodiment provides another electric grinder.

[0087] Please refer to Figure 15 , 16 and 17, the electric grinder has been improved on the structure shown in Embodiment 1, and the original Figure 9 or Figure 10 Two or more clamping holes are added on the grinding head, and a second grinding head 930 can be externally connected. The second grinding head 930 can have a grinding surface 463 of a circular arc, and the cross section of the grinding surface 463 is as reference Figure 11 , used to grind the hard skin of the skin, fixed on the Figure 9 or Figure 10 on the grinding head.

[0088] Likewise, please refer to Figure 17 , The second grinding head 930 can also be provided with a sheath 922 of soft material to block the periphery of the second grinding head 930 to prevent the grinding debris from moving to the handle part.

[0089] In addition, the second grinding head 930 can also be a grinding head for grinding nails, while the original grin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com