Dry type wafer polishing device and method

A dry polishing and wafer technology, which is applied to grinding drives, grinding/polishing equipment, surface polishing machine tools, etc. Simple, balanced gravity, overall compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

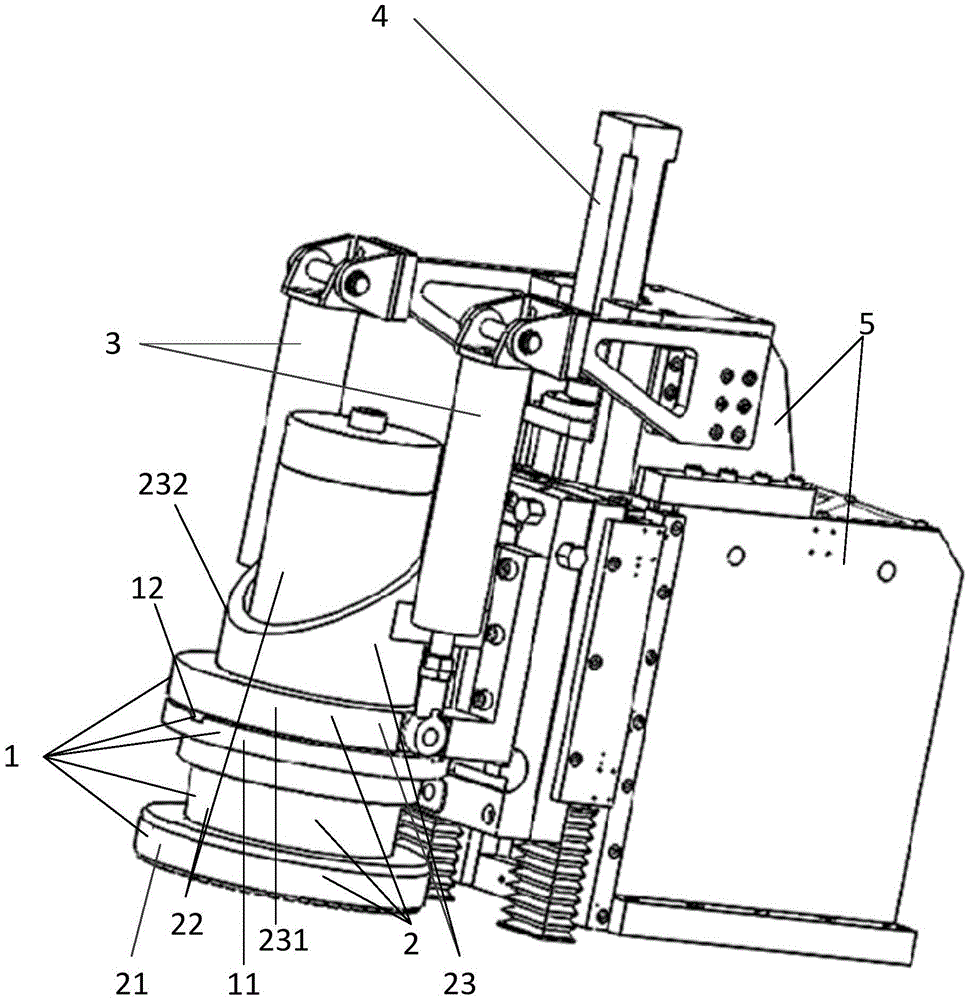

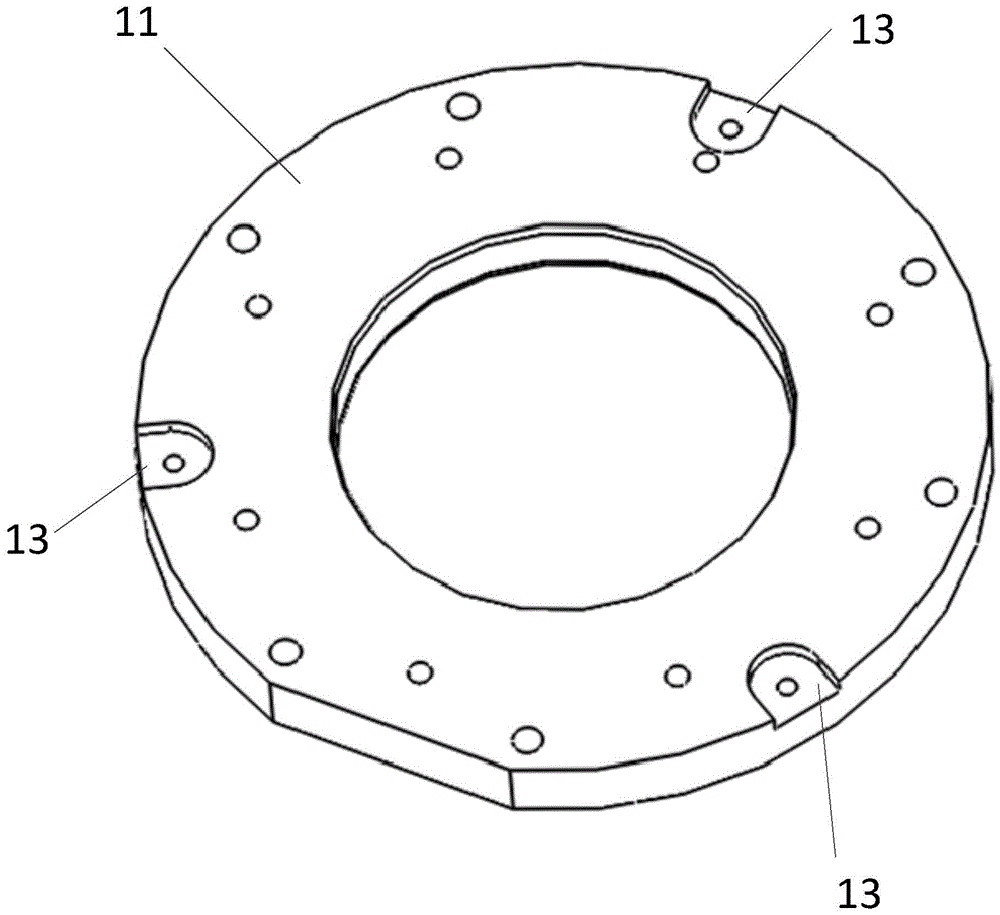

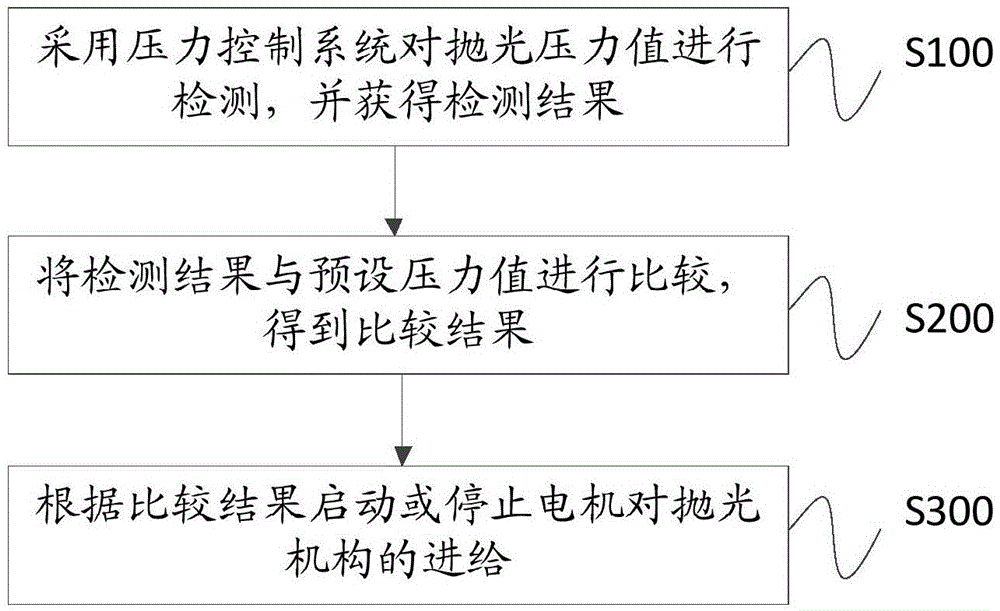

[0035] Embodiments of the present invention provide a wafer dry polishing device, such as figure 1 As shown, it includes: a pressure control system 1 arranged on the workbench for detecting the polishing pressure value, the pressure control system 1 includes a polishing mechanism 2; a cylinder 3 connected with the polishing mechanism 2 and a frame 5; and a polishing mechanism 2 A motor 4 connected to the frame 5 for driving the movement of the polishing mechanism 2; wherein, the cylinder 3 is fixedly connected to the polishing mechanism 2, and the motor 4 is located above the polishing mechanism 2 and connected to the polishing mechanism 2.

[0036] Specifically, the embodiments of the present invention are used for semiconductor special equipment for pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com