Preparation method for steel wire mesh enhanced laminated veneer lumber based on target mechanical property

A technology of laminated veneer lumber and target mechanics, which is applied in the jointing of wooden veneers, manufacturing tools, wood processing appliances, etc. Stiffness requirements and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

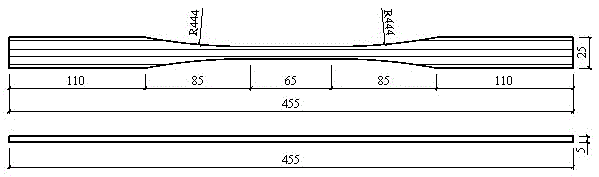

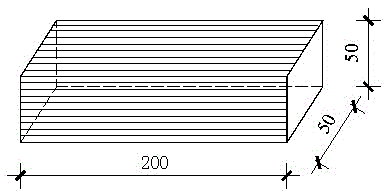

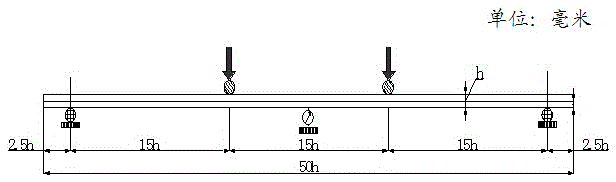

[0027] A method for preparing a steel mesh reinforced laminated veneer lumber based on target mechanical properties, comprising the following steps:

[0028] 1) Remove the branches, leaves, bark, broken material, soften, and rotary cut the felled adult fast-growing wood into veneers (the thickness t of the veneer is specified as: 1.5mm≤t≤5.0mm), and dry it at a constant temperature to make it contain water rate reaches the predetermined standard (not greater than 12%);

[0029] 2) Use digital imaging technology to stack the dried veneers in grades according to the wood grade classification standards. The wood grade standards are shown in Table 1:

[0030] Table 1 Material standards for visual classification of load-bearing structural plates

[0031]

[0032] 3) According to the target mechanical properties of the end product, tensile, compressive, bending, shear strength values along the grain, and modulus of elasticity along the grain, through numerical tests and refine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com