Dimming composite vacuum glass and preparing method thereof

A vacuum glass and dimming technology, which is applied in chemical instruments and methods, glass/slag layered products, optics, etc., can solve the problems of not very ideal thermal insulation performance, lack of dimming glass characteristics, and large glass thickness, etc., to achieve Enhance the effect of heat insulation, avoid damage, and ensure the effect of transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

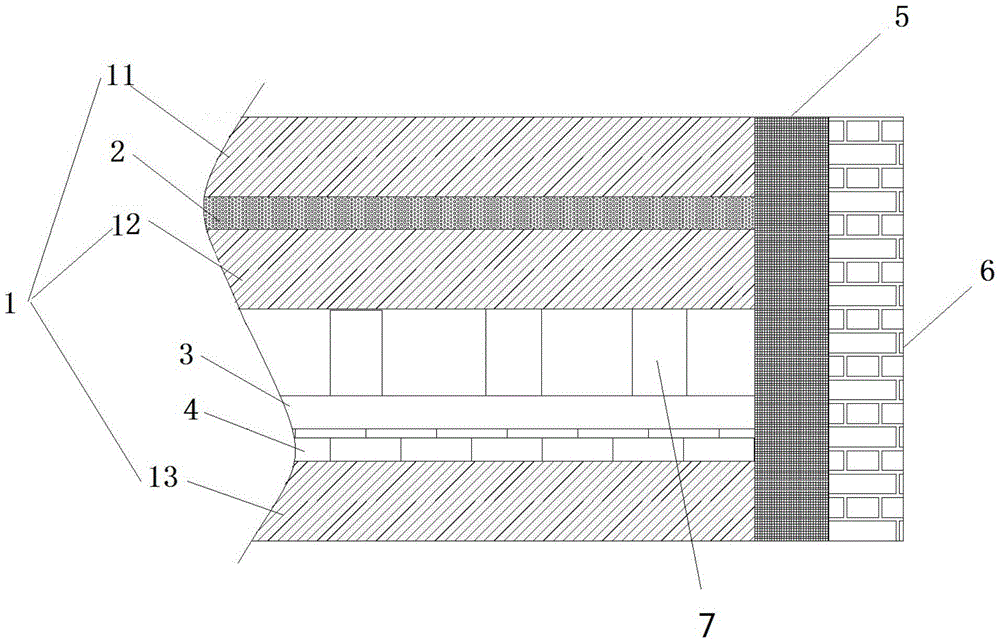

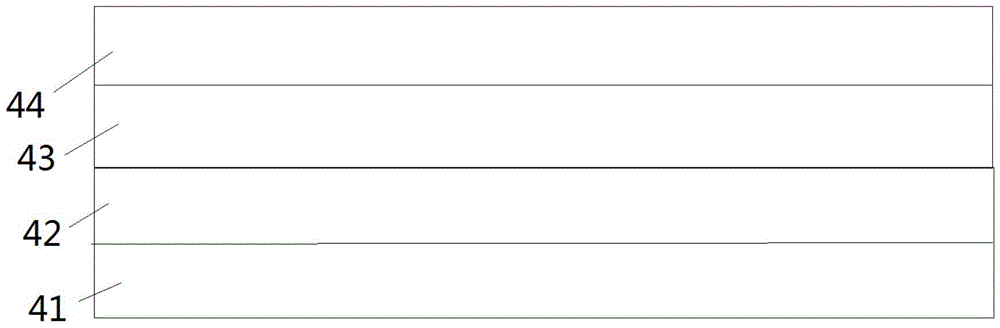

[0018] refer to Figure 1~Figure 2 , a kind of dimmable composite vacuum glass provided by the present invention and its preparation method include: a glass layer 1, including: a first transparent conductive thick glass layer 11 stacked from top to bottom, a second transparent conductive thick glass layer Layer 12, the third glass layer 13; polymer dispersed negative liquid crystal layer 2, arranged between the first transparent conductive thick glass layer 11 and the second transparent conductive thick glass layer 12; infrared reflection layer 4, arranged on the third glass layer The upper surface of the layer 13; the stress protection layer 3 is arranged on the upper surface of the infrared reflection layer 4; the sealing layer 5 is coated around the glass layer 1 along the direction perpendicular to the glass layer 1; the protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com