Multi-axis aircraft

A multi-rotor aircraft and propeller technology, applied in the field of unmanned aerial vehicles, can solve the problems of aircraft flexibility and stability, low lift and weight of multi-axis aircraft, poor flexibility and stability of aircraft, etc., to improve the accuracy and sensitivity of remote control. Performance, simple and robust construction, the effect of improving flexibility and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

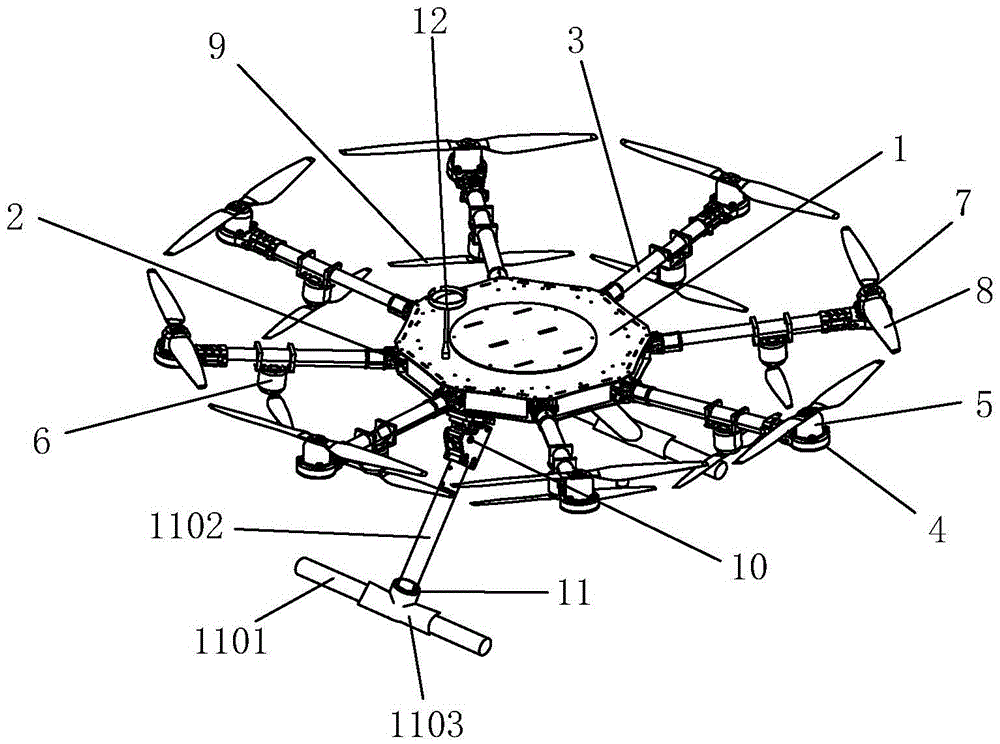

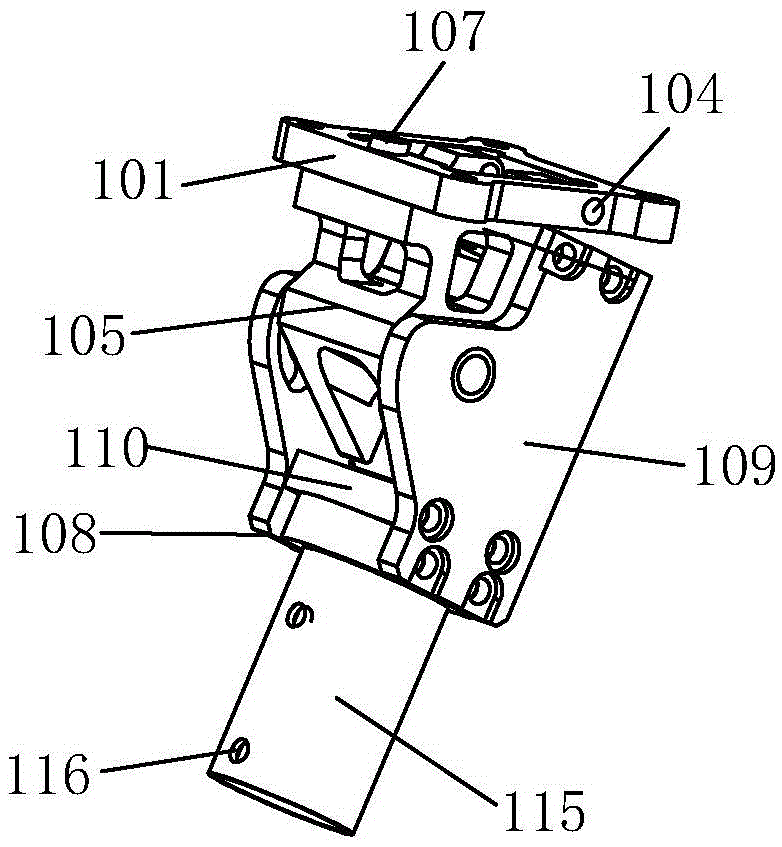

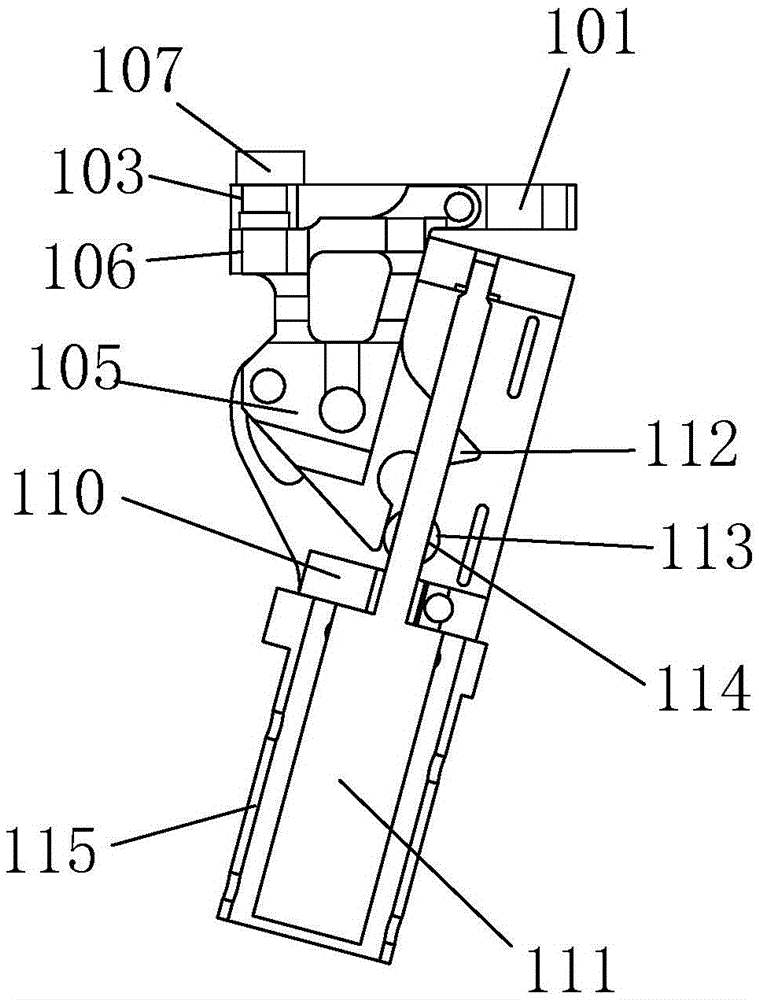

[0042] As shown in the figure, a multi-axis aircraft includes a frame 1, a pipe clamp 2, and a machine arm 3. The pipe clamp 2 is evenly distributed on the side of the frame 1, and the inner end of the machine arm 3 is connected with the pipe clamp 2. The machine arm 3. The outer end is provided with a motor seat 4, and the motor seat 4 is provided with a positive motor 5, and the middle of the machine arm 3 is provided with a reverse motor 6, and the rotating shafts of the normal motor 5 and the reverse motor 6 are provided with a propeller easy-to-install structure 7, and the normal The propeller easy-to-install structure 7 on the motor 5 is provided with a propeller 8, and the propeller 8 is located above the machine arm 3, and the propeller easy-to-install structure 7 on the motor 6 is provided with a reverse propeller 9, and the reverse propeller 9 is located on the machine arm. Below the arm 3, an electric tripod folding device 10 is provided at the bottom of the frame 1,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com