A multi-energy-driven seawater salt production tower and salt production process

A multi-energy, seawater technology, applied in seawater treatment, energy input, water/sewage treatment, etc., can solve the problems of low operation efficiency, large tidal flat area, low production efficiency, etc., and achieve high production efficiency, less tidal flat occupation, The effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

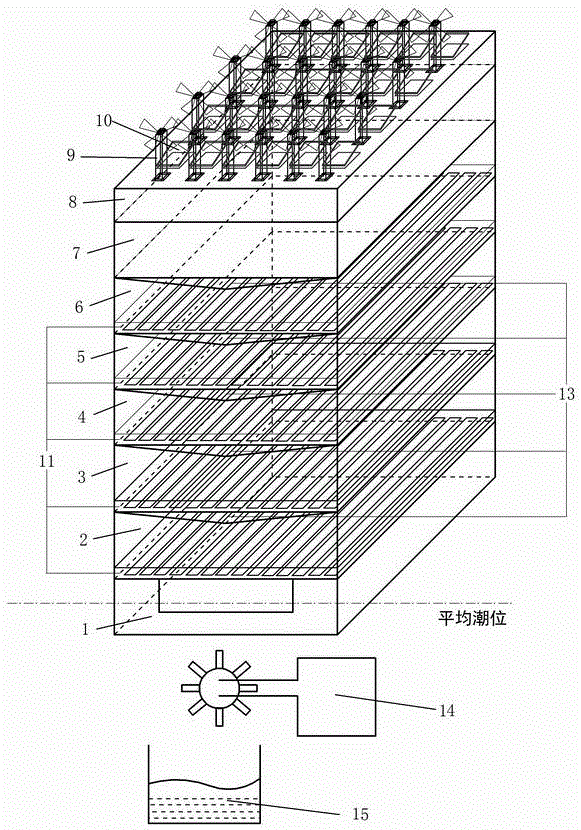

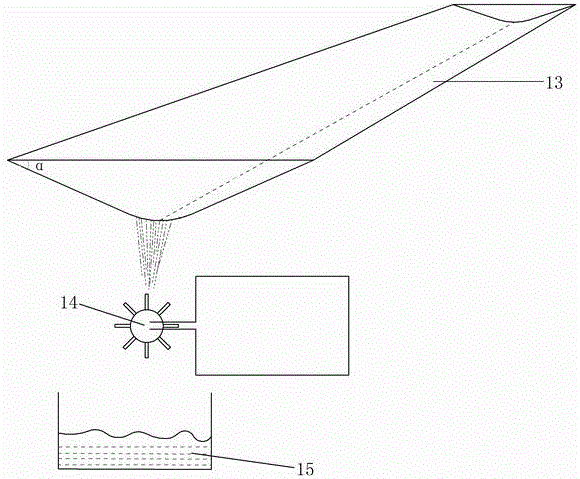

[0019] figure 1 It shows the structure of a multi-energy-driven seawater salt production tower, which is sequentially provided with a tidal pool 1, a first evaporation pool 2, a second evaporation pool 3, a primary brine production pool 4, and an intermediate brine production tank from bottom to top. pool 5, high-grade brine making pool 6, crystallization pool 7, and salt storage pool 8; the depth of the tide pool 1 that is dug under the ground is more than twice the depth of the evaporation pool, and the first evaporation pool 2 is located above the ground; the first evaporation pool The pool 2, the second evaporation pool 3, the primary brine production pool 4, the intermediate brine production pool 5, the advanced brine production pool 6 and the crystallization pool 7 are seawater concentration ponds, and electric heaters 11 are installed at the bottom of each seawater concentration pond. The distilled water collection device installed on the top of the upper space of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com