Device for synthesizing nitromethane and separating products

A separation device and nitromethane technology, applied in the field of nitromethane synthesis and product separation devices, can solve the problems of high steam energy consumption, increased manpower input, discontinuous process, etc., so as to improve the utilization rate of raw materials and reduce manpower input , a uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

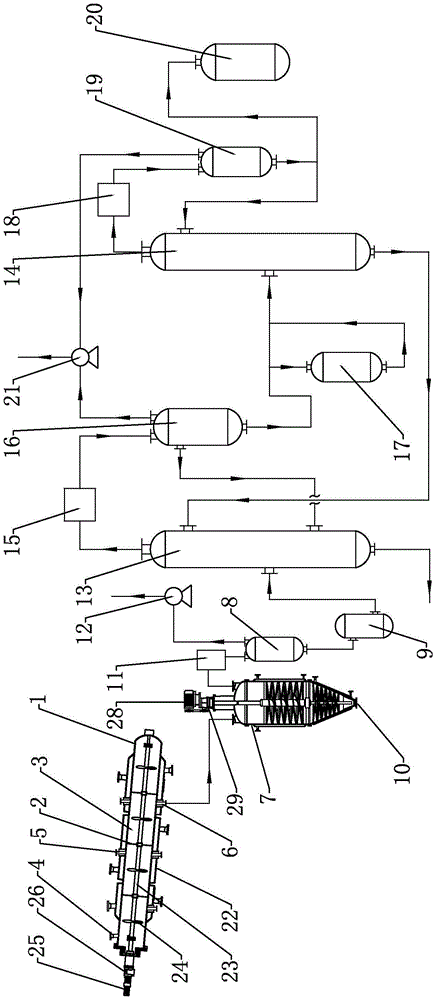

[0029] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

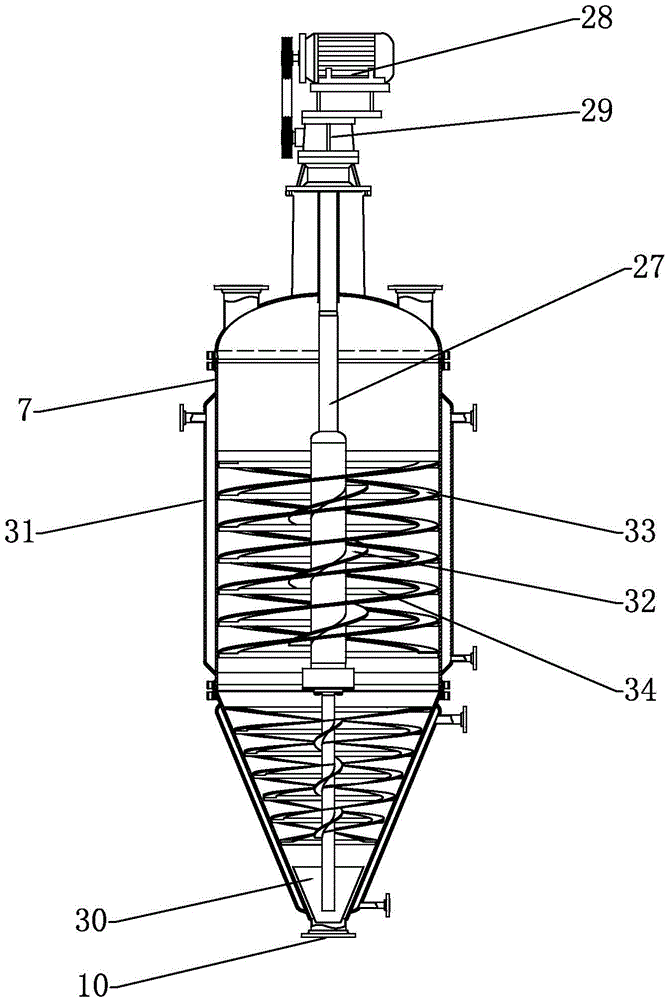

[0030] Such as Figure 1-Figure 2 As shown in , this embodiment includes a horizontal reactor 1, a product separation device and a product purification device sequentially connected from front to back, and the angle between the axis direction of the horizontal reactor shell and the horizontal plane is 0-20°, The cavity of the horizontal reactor 1 is divided into several interconnected reaction units 3 by several baffles 2, and in the cavity of the horizontal reactor 1 along the axial direction of the horizontal reactor 1, a A reactor stirring mechanism of a reaction unit 3, the front end of the reactor stirring mechanism passes through the head end side wall of the horizontal reactor 1 and is connected with a reactor driving mechanism, on the higher side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com