Solid type pigment composition and preparation method thereof

A technology of pigment composition and aluminum pigment, applied in the direction of inorganic pigment treatment, chemical instruments and methods, dyeing low-molecular organic compound treatment, etc., can solve the problem of increasing paint and ink, reducing product environmental protection rating, aluminum pigment removal and weighing Convenience and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

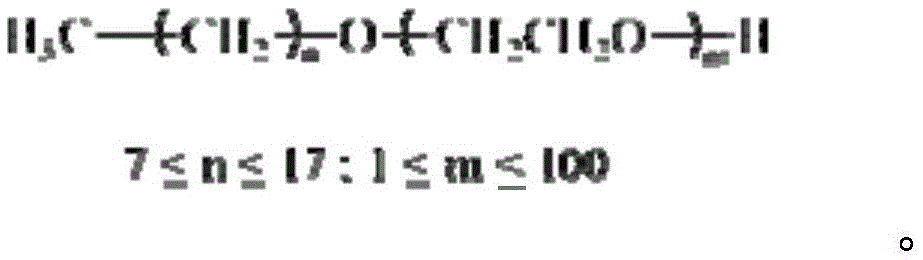

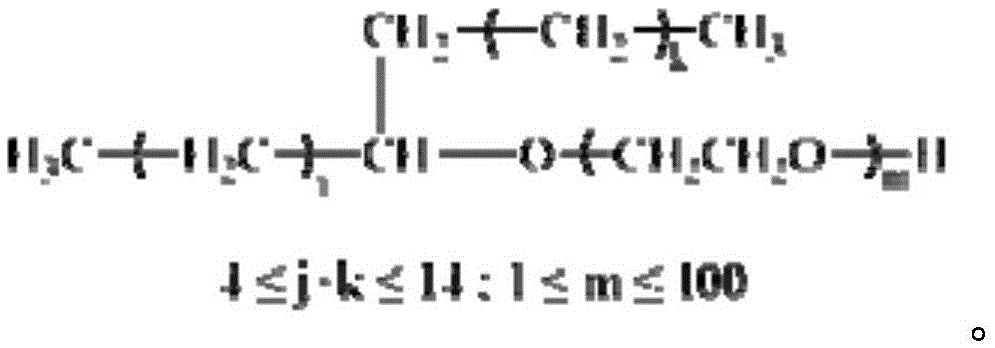

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of above-mentioned high water dispersibility solid pigment composition, comprises the following steps:

[0047] Step S110, stirring and mixing aluminum pigment slurry (containing 55%-85% aluminum pigment particles, 15%-45% solvent), dispersant, splitting agent and 0-15 parts of solvent to obtain a mixture, the solvent and dispersant compatible.

[0048] Preferably, the aluminum pigment is added in the form of slurry, and the slurry contains 55% to 85% of aluminum pigment and 15% to 45% of solvent in terms of mass percentage.

[0049] Preferably, the water-soluble aluminum pigment, dispersant, splitting agent and solvent are sequentially added into the mixer for stirring treatment. More preferably, the time for the stirring treatment is 1 to 2 hours.

[0050] Preferably, the choice of solvent needs to meet the following four conditions: (1) must be a non-toxic and harmless solvent; (2) incompatible with pigments and dispersants, thus producing th...

Embodiment 1

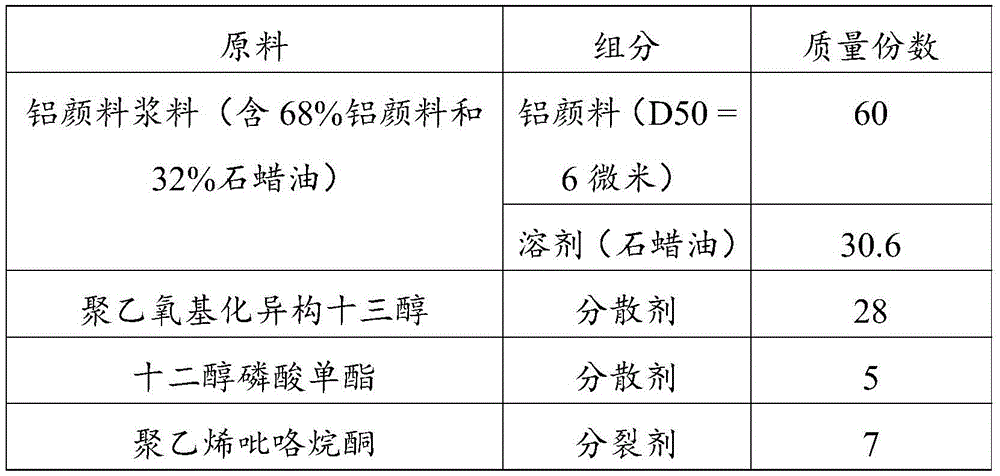

[0063] The composition of the highly water-dispersible solid pigment composition of embodiment 1 is as shown in table 1:

[0064] Table 1

[0065]

Embodiment 2

[0067] The composition of the highly water-dispersible solid pigment composition of embodiment 2 is as shown in table 2:

[0068] Table 2

[0069]

[0070]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com