A dyeing machine power system with self-pressurization function

A power system and dyeing machine technology, applied in the field of dyeing machinery, can solve problems such as consumption, increase economic cost, increase environmental pollution sources, etc., and achieve the effects of improving process efficiency, reducing economic cost, and increasing NPSH

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific examples, but the protection and implementation of the present invention are not limited thereto. It should be pointed out that if there are no specific details below, those skilled in the art can refer to the prior art to understand or achieved.

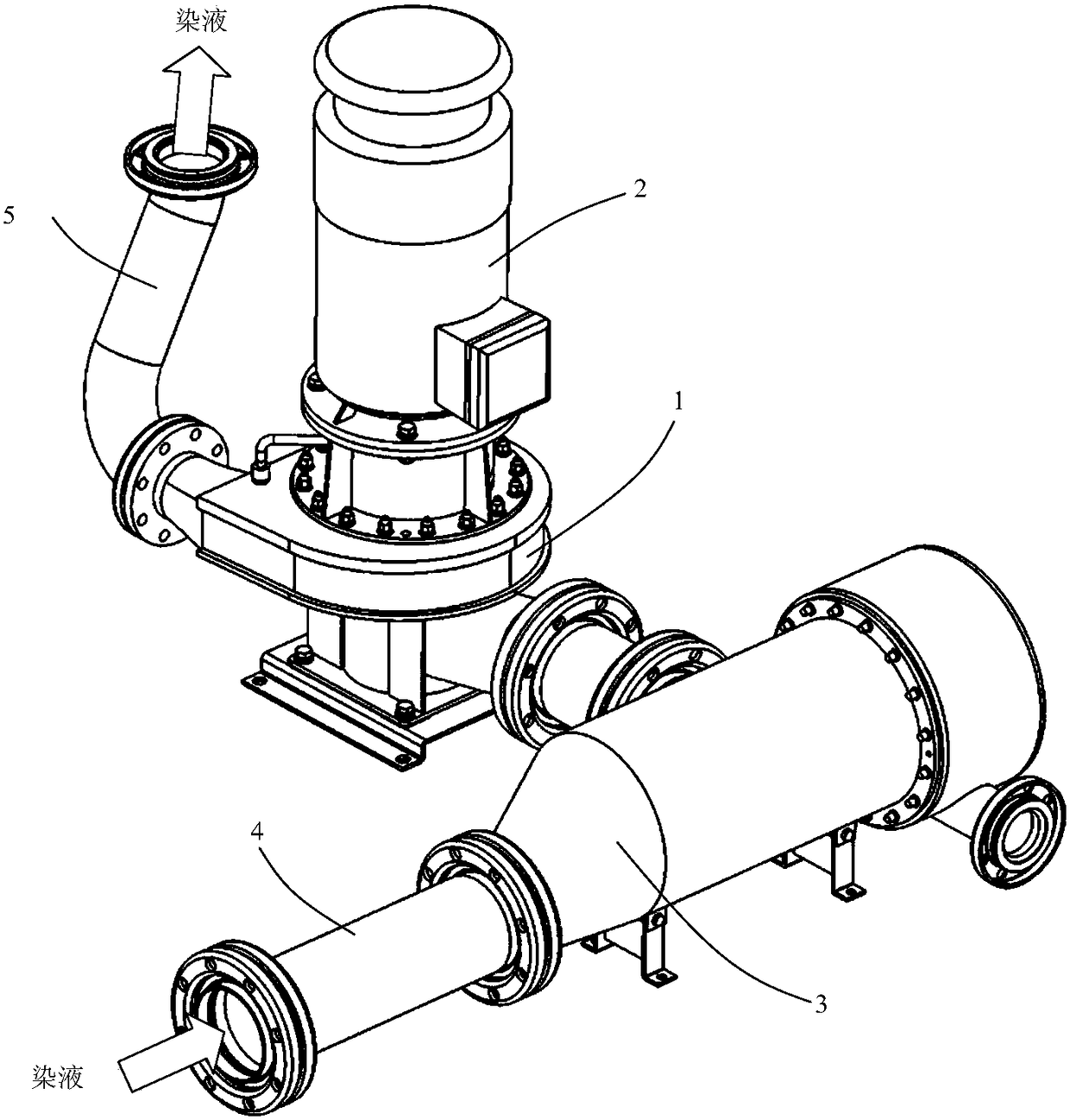

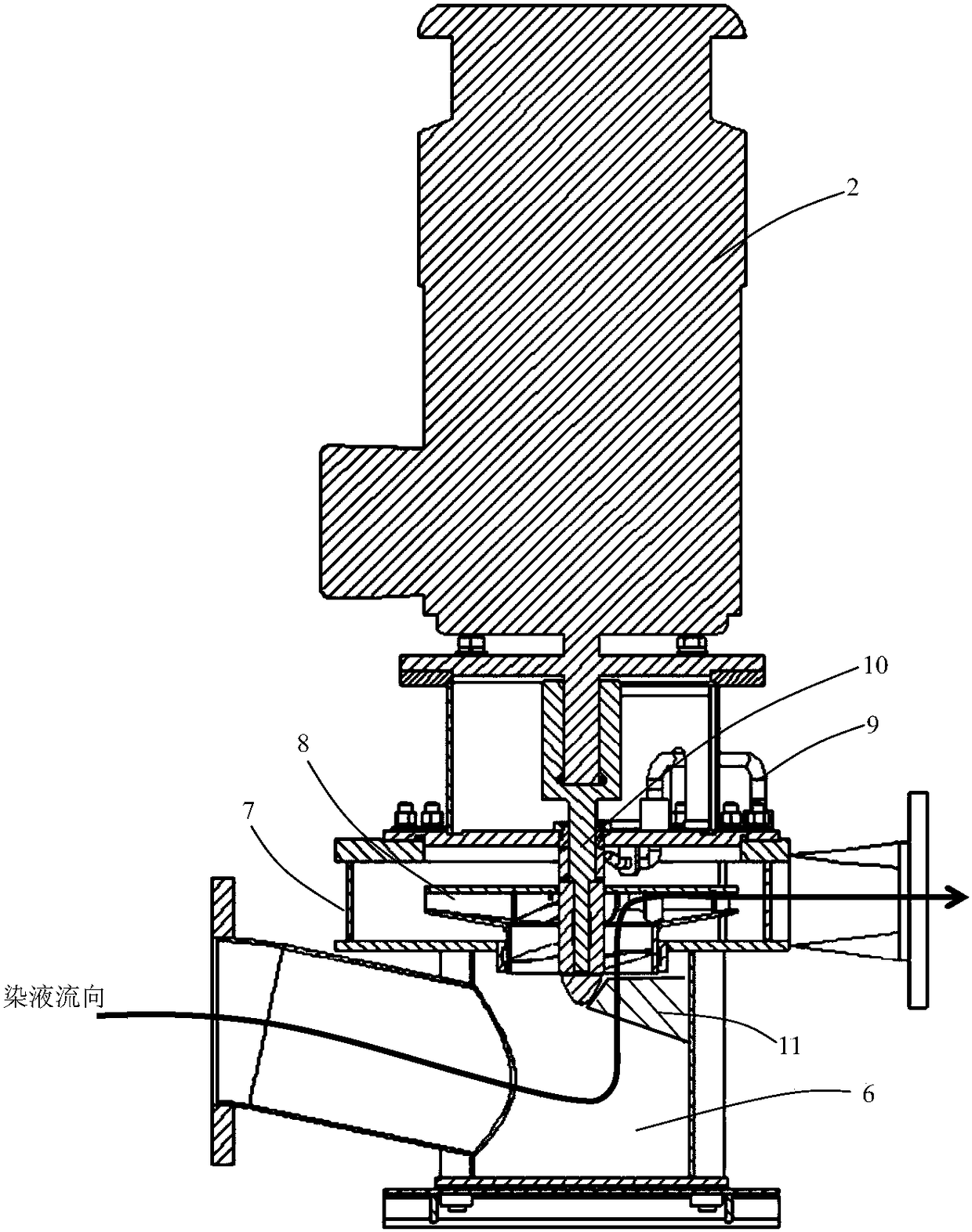

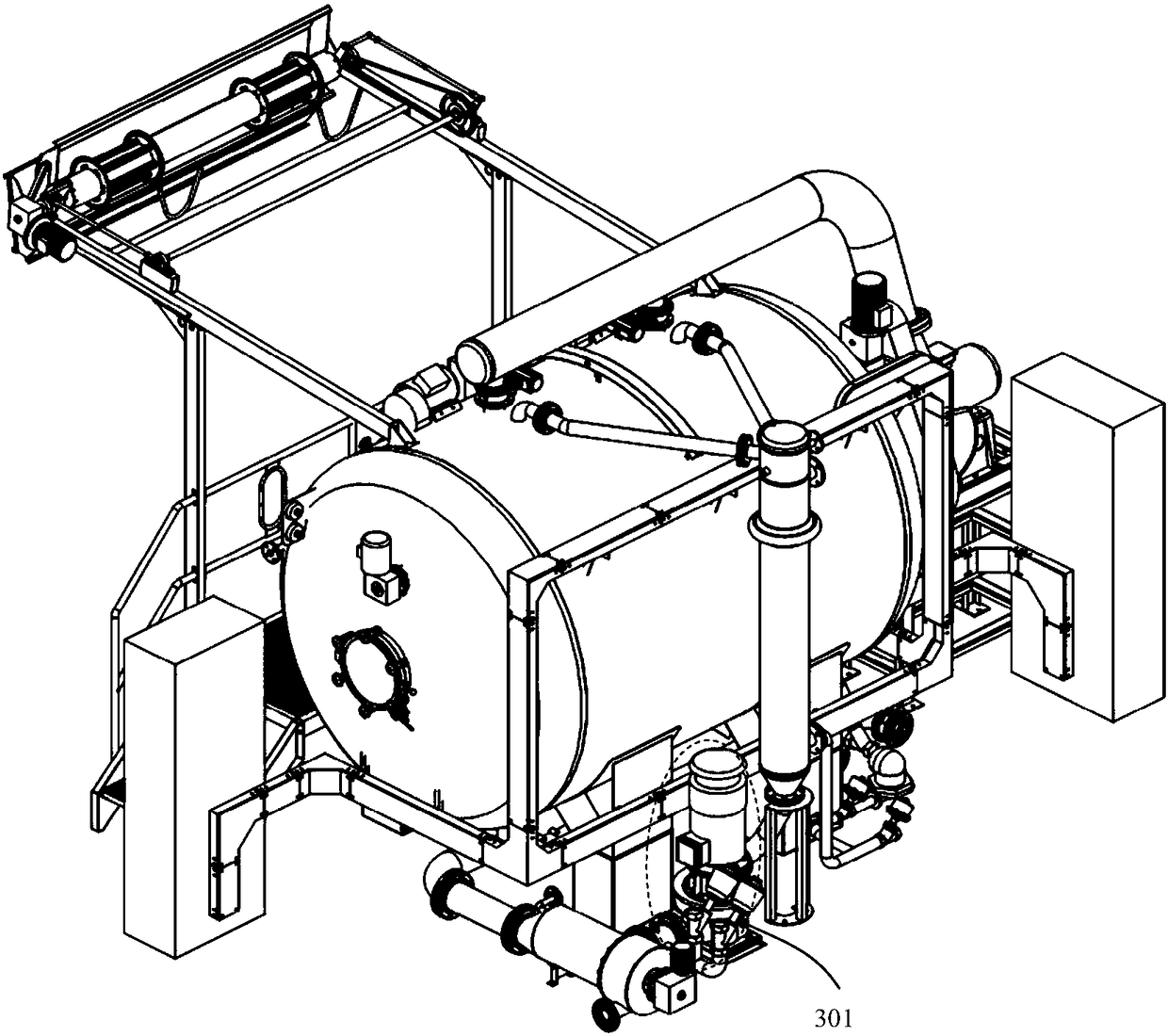

[0024] Such as Figure 1~Figure 7 As shown, a dyeing machine power system with a self-pressurizing function mainly includes a pump assembly 1, a motor 2, a variable diameter pipe 3, a dye liquor inlet pipe 4, a dye liquor outlet pipe 5, a liquid storage chamber 6, and a volute 7 , Two-stage impeller 8, cooling pipe 9, sealing assembly 10, spoiler 11, coupling 12, flange cover 13, nozzle 14 and other components.

[0025] The diameter reducing pipe 3 is a tapered pipe with one end larger and the other end small; the dye liquor inlet pipe 4 is connected to the small end of the diameter reducing pipe 3, and the large end of the diameter reducing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com