High-extension copper tire based root puncture-resistant waterproofing coiled material and preparation method thereof

A waterproof membrane and root puncture-resistant technology, which is applied in the direction of textiles and papermaking, can solve the problem that the elongation and puncture resistance of the copper base waterproof membrane cannot be achieved, the waterproof performance and deformation resistance are not high, and the copper base waterproof Low coil elongation and other problems, to achieve the effects of strong shrinkage deformation and cracking adaptability, good waterproof effect, high elongation, deformation resistance and root resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

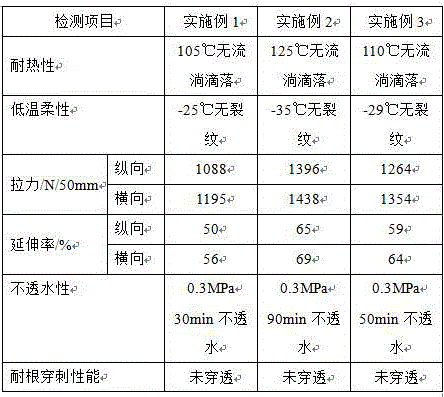

Examples

Embodiment 1

[0037] Example 1 A high-stretch copper base puncture-resistant waterproof membrane

[0038] The waterproof coiled material is a three-layer composite structure, the middle layer is a composite copper base non-woven fabric, and the upper and lower surfaces of the composite copper base non-woven fabric are modified asphalt coatings;

[0039] The thickness of the middle layer is 2mm, and the thickness of the upper and lower layers of modified asphalt coating is 1mm;

[0040] The composite copper base non-woven fabric: longitudinal elongation ≥ 40%, transverse elongation ≥ 40%, thickness 2mm;

[0041] The modified asphalt coating is a polymer modified asphalt coating, which contains the following components in parts by mass:

[0042] 100 parts of base asphalt, 10 parts of softener, 12 parts of modifier, 5 parts of extension accelerator, 0.1 part of antioxidant, 0.3 part of propionate derivative;

[0043] The softener is naphthenic oil: freezing point ≤ -20°C, volatile matter ≤ 1...

Embodiment 2

[0062] Example 2 A high-stretch copper base puncture-resistant waterproof membrane

[0063] The waterproof coiled material is a three-layer composite structure, the middle layer is a composite copper base non-woven fabric, and the upper and lower surfaces of the composite copper base non-woven fabric are modified asphalt coatings;

[0064] The thickness of the middle layer is 2mm, and the thickness of the upper and lower layers of modified asphalt coating is 1mm;

[0065] The composite copper base non-woven fabric: longitudinal elongation ≥ 40%, transverse elongation ≥ 40%, thickness 2mm;

[0066] The modified asphalt coating is a polymer modified asphalt coating, which contains the following components in parts by mass:

[0067] 100 parts of base asphalt, 15 parts of softener, 15 parts of modifier, 8 parts of extension accelerator, 0.3 part of antioxidant, 0.5 part of propionate derivative;

[0068] The softener is engine oil: freezing point ≤ -25°C, volatile matter ≤1%, flas...

Embodiment 3

[0078] Example 3 A high-stretch copper base puncture-resistant waterproof membrane

[0079] The waterproof coiled material is a three-layer composite structure, the middle layer is a composite copper base non-woven fabric, and the upper and lower surfaces of the composite copper base non-woven fabric are modified asphalt coatings;

[0080] The thickness of the middle layer is 2mm, and the thickness of the upper and lower layers of modified asphalt coating is 1mm;

[0081] The composite copper base non-woven fabric: longitudinal elongation ≥ 40%, transverse elongation ≥ 40%, thickness 2mm;

[0082] The modified asphalt coating is a polymer modified asphalt coating, which contains the following components in parts by mass:

[0083] 100 parts of base asphalt, 20 parts of softener, 20 parts of modifier, 12 parts of extension accelerator, 0.5 part of antioxidant, 0.8 part of propionate derivative;

[0084] The softener is aromatic oil: freezing point≤-30°C, volatile matter≤1%, fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com