Online rapid repairing device for dewaterer gear ring

A technology of dehydrator and ring gear, which is applied in hoisting devices, portable lifting devices, components with teeth, etc., can solve the problems of increased wear, long construction period, and difficult construction, so as to facilitate quick replacement and reduce labor Strength, the effect of improving repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

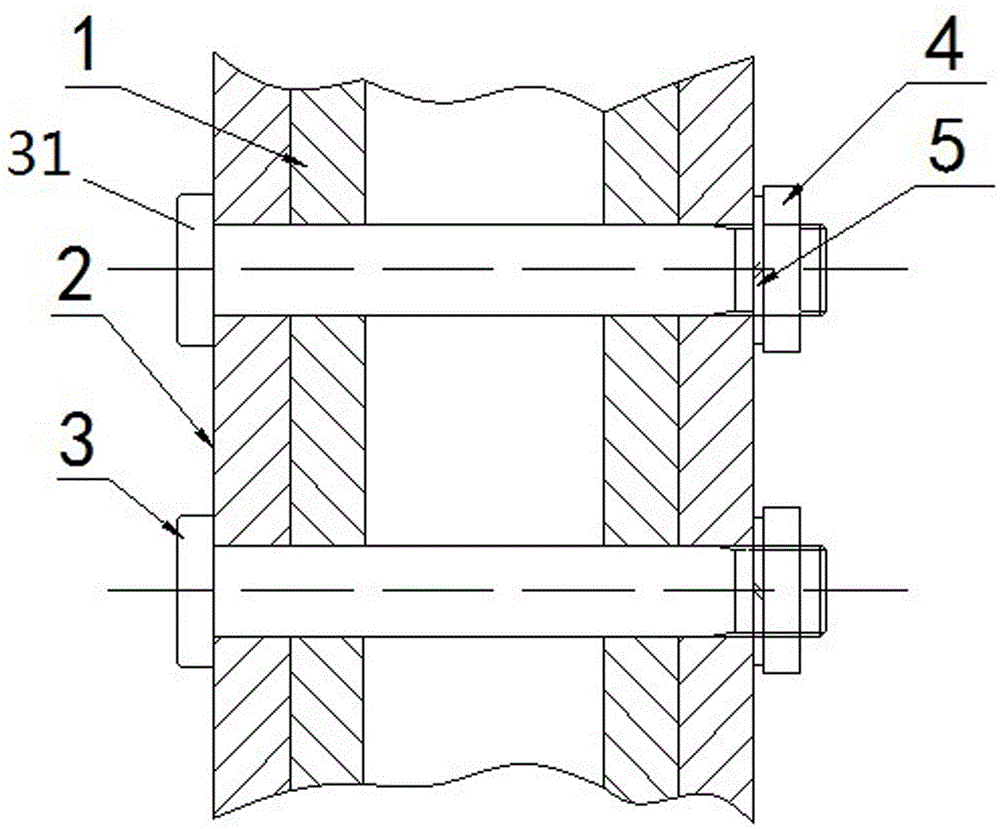

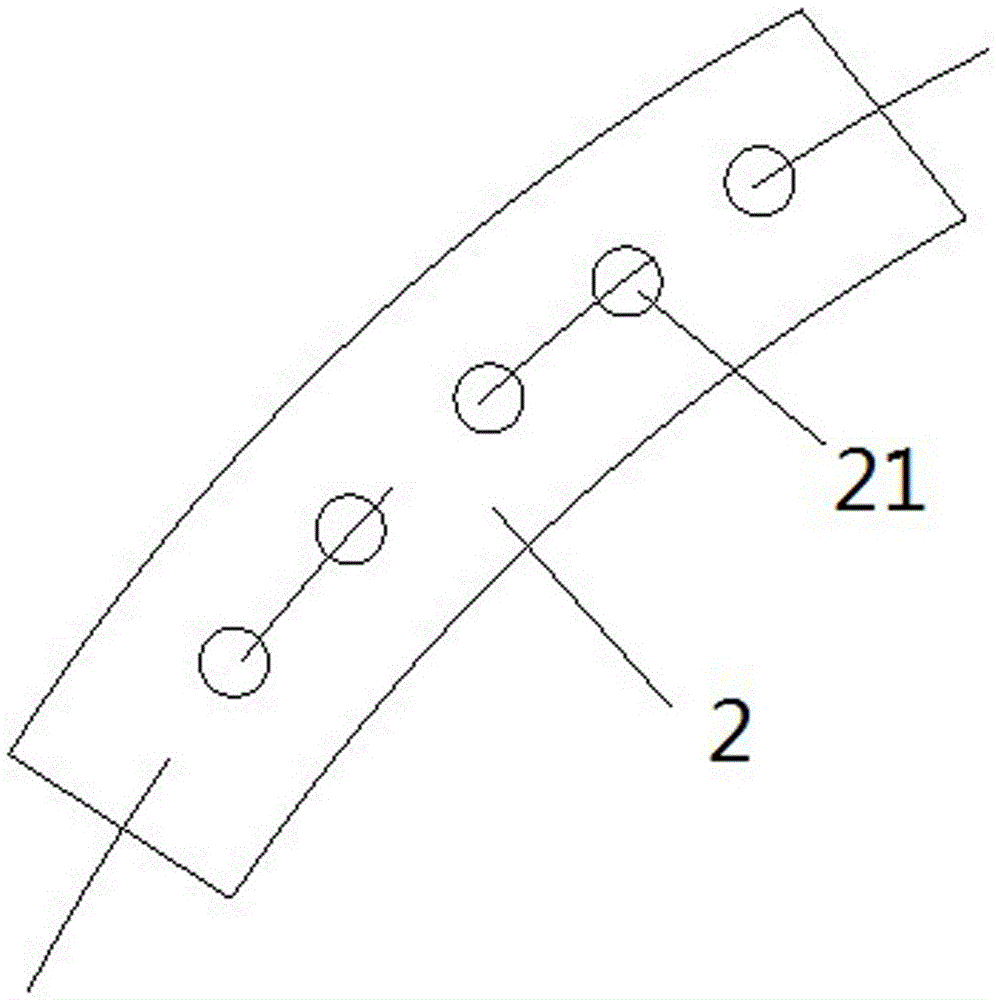

[0016] Such as figure 1 and figure 2 As shown, an online rapid repair device for a dehydrator ring gear of the present invention includes a ring gear 1, the ring gear is composed of two semicircular support rings, through holes are evenly distributed on the support rings, and the outer side of the support rings is fixedly welded with The arc-shaped plate 2 mainly plays the role of fixing the supporting pin, and the size of the arc-shaped plate is made according to the parts that need to be replaced on site. The arc plate 2 is provided with a connection hole 21. Specifically, the position of the connection hole 21 corresponds to the position of the through hole on the support ring. A pin shaft 3 is installed in the connection hole 21 and the through hole, and the pin shaft passes through the arc plate. To realize the connection with the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com