Rapid wear test system and rapid wear test method for AMT clutch plate

A wear test and clutch technology, applied in the field of automobile clutch performance test, to achieve the effects of accurate and reliable test data, reliable working principle and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

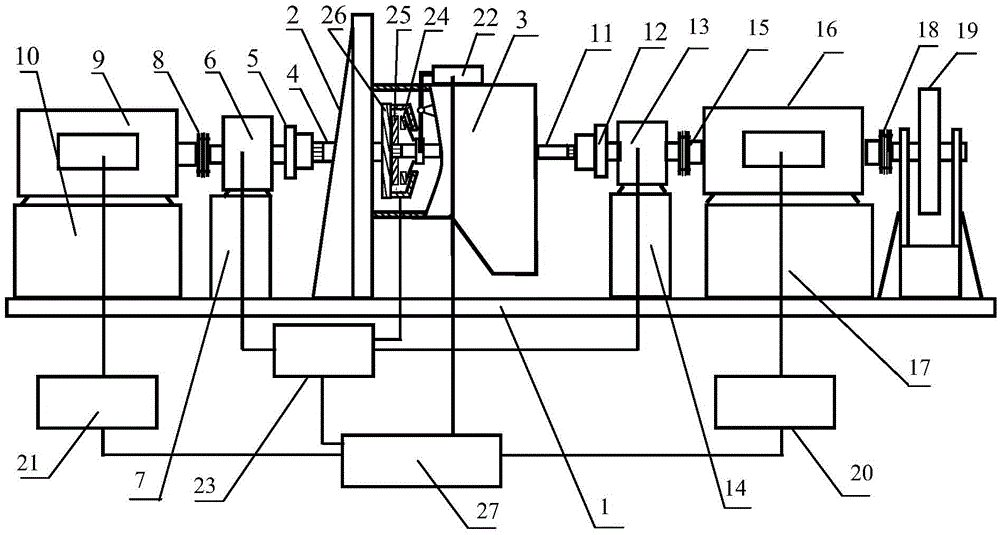

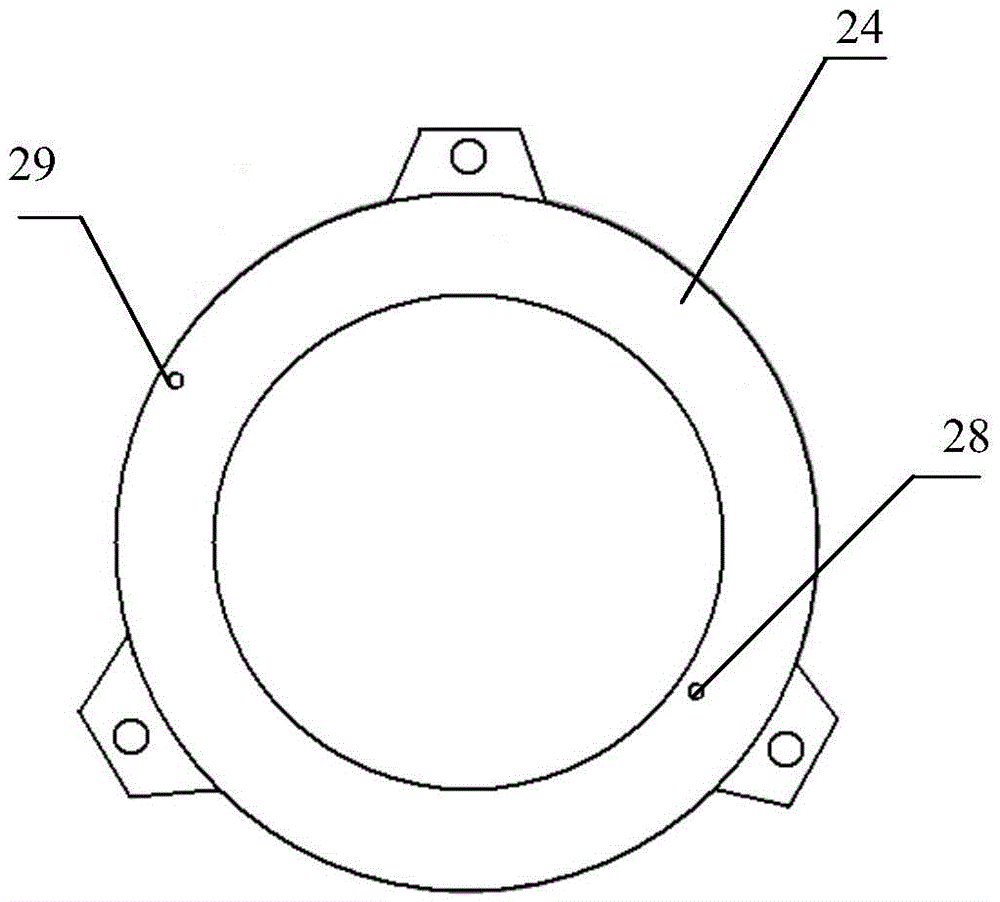

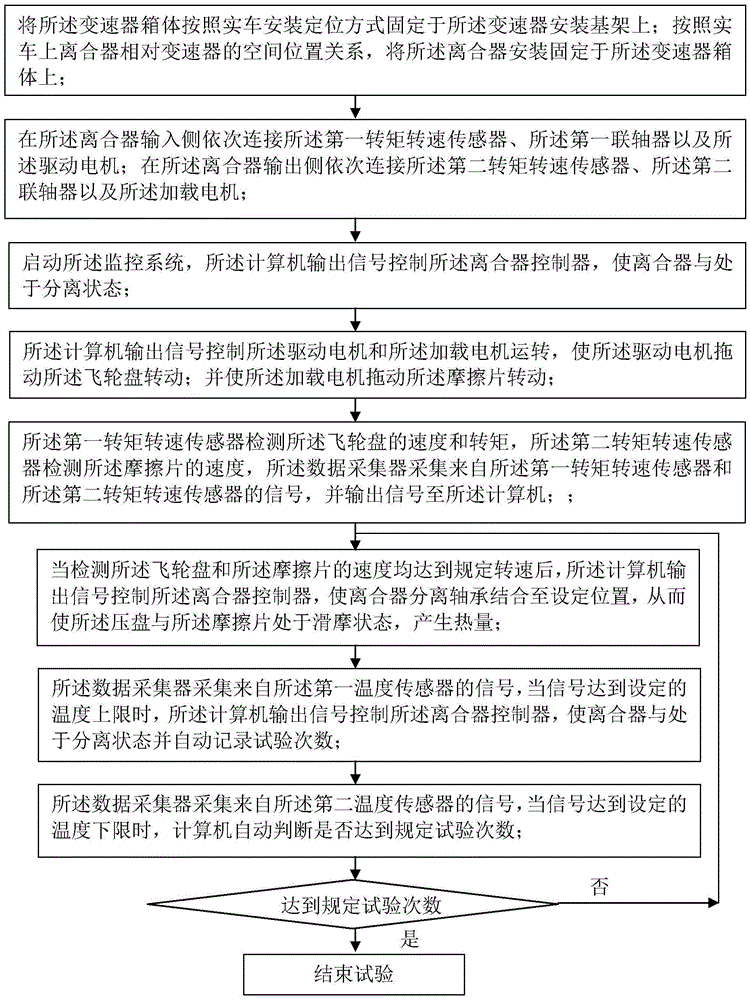

[0030] see figure 1 and figure 2 , a kind of AMT clutch friction plate rapid wear test system, comprises transmission casing 3, the clutch that is installed in this transmission casing 3 and clutch controller 22; Described clutch is provided with flywheel disc 26, The friction plate 25 and the pressure plate 24, the pressure plate 24 is installed on the clutch release bearing, and also includes the drive motor 9, the first shaft coupling 8, the first torque speed sensor 6, the second torque speed sensor 13, the first Two shaft couplings 15, a loading motor 16 and the transmission installation base 2 of the transmission casing 3 are fixedly installed, and the first torque speed sensor 6 and the first shaft coupling are connected in sequence ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com