A Measuring Method of Interdiffusion Coefficient Eliminating the Effect of Cooling Process

A technology of interdiffusion coefficient and measurement method, which is applied in the field of alloy melt interdiffusion, can solve the problems of interdiffusion experiment, cumbersome operation, error reduction, etc., and achieve the effect of easy measurement experiment, convenient experiment operation and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

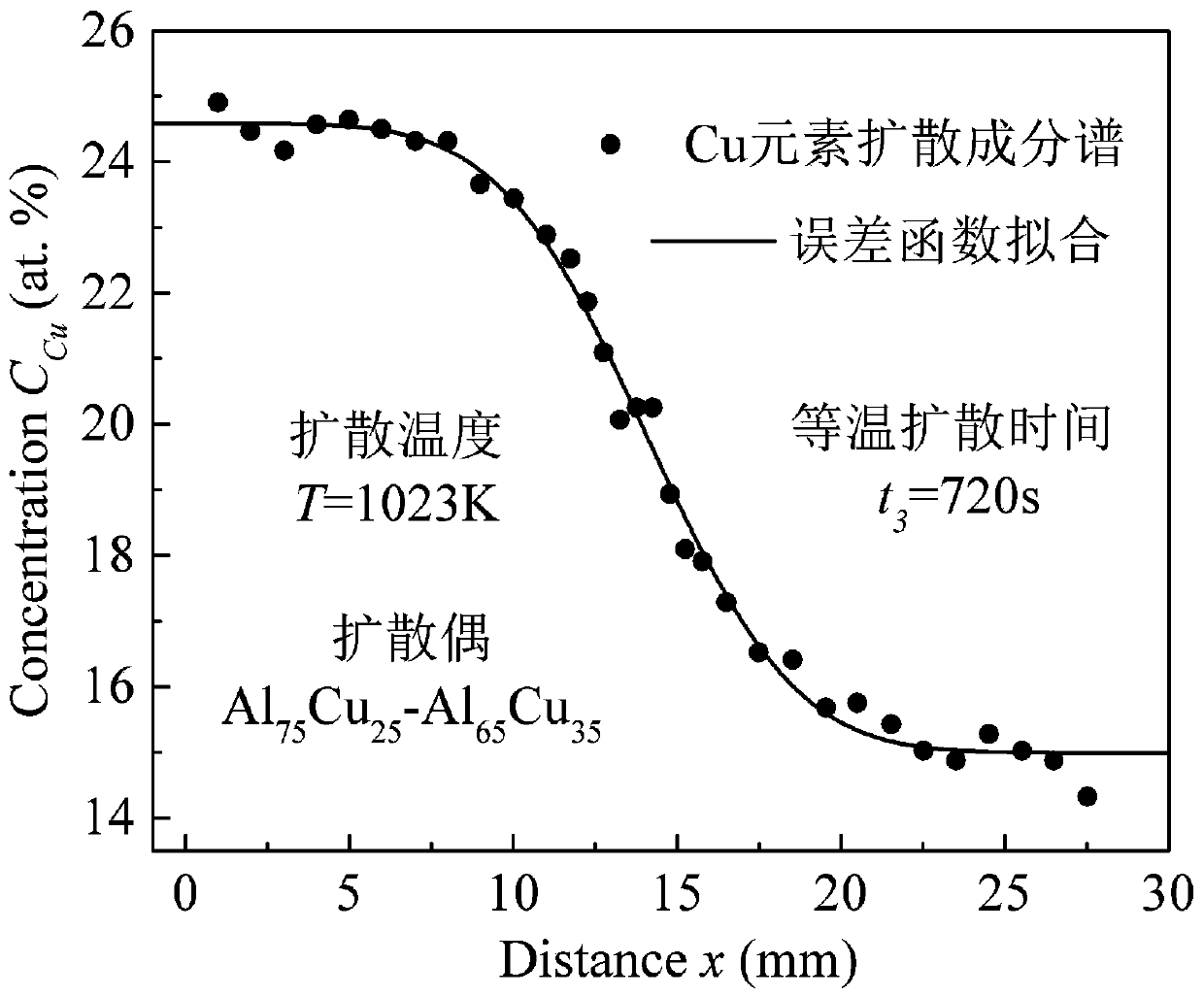

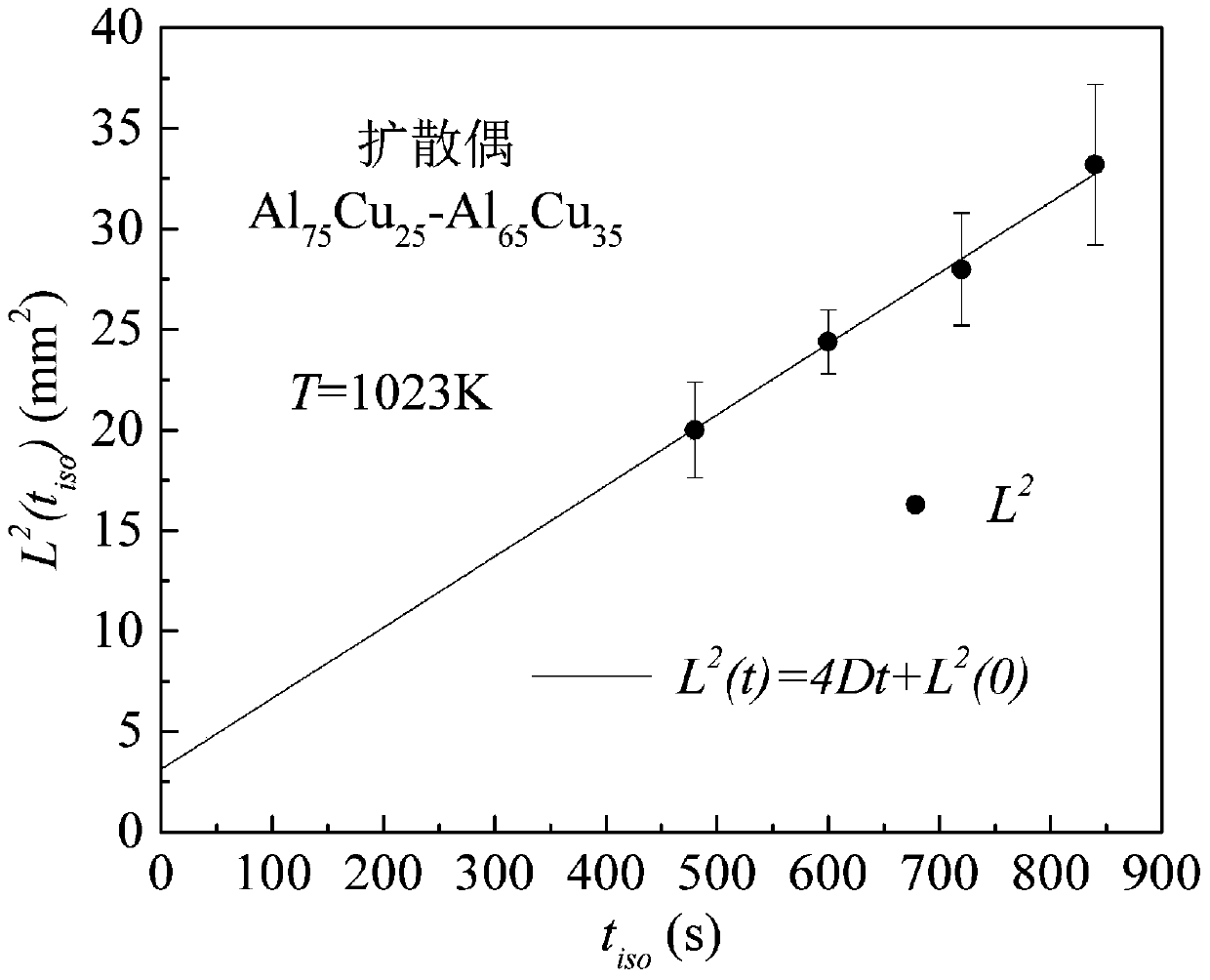

[0033] In order to further discuss the present invention, the diffusion couple Al will be combined below 75 Cu 25 -Al 65 Cu 35 The diffusion behavior is described in detail. According to the selected diffusion couple composition, consult the Al-Cu binary alloy phase diagram, and determine the isothermal diffusion temperature of the experiment according to the liquidus temperature, which is 1023K in this example. Diffusion samples of diffusion couple components are prepared, and the raw materials used in the samples in this example are Al and Cu with a purity of 99.99%. A rod-shaped sample with a diameter of 2 mm was sucked and casted in a vacuum melting furnace. Argon protection was used during the sucking casting process. In order to ensure uniform composition, the sample needs to be melted at least 5 times in the vacuum melting furnace.

[0034] Utilize the present invention to solve the diffusion couple Al 75 Cu 25 -Al 65 Cu 35 The interdiffusion coefficient at 1023K ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com