Online real-time monitoring system and method for monitoring heat shrinkage rate of lithium battery diaphragm

A technology of thermal shrinkage and real-time monitoring, applied in the online real-time monitoring of the thermal shrinkage rate of lithium-ion battery separators, and the field of online real-time monitoring of the thermal shrinkage rate of battery separators. The problem of slow detection speed, etc., achieves the effect of facilitating the quality of the battery separator, convenient installation, and overcoming the time-consuming and labor-intensive effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

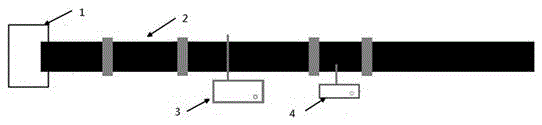

[0029] Such as figure 1 As shown, the online real-time monitoring thermal shrinkage rate system of the lithium-ion battery diaphragm provided by the present invention includes an infrared heating device 3 and a stress testing device 4 successively set up at the exit 1 of the stretching film forming of the diaphragm production line, and the infrared heating device 3 and the stress testing device The height of the detection port of 4 is respectively equal to the membrane surface of the outlet membrane (battery diaphragm) 2;

[0030] The infrared heating device and the stress testing device are respectively connected to the display device, and the display device has a built-in control system, and the corresponding test parameters of the infrared heating device and the stress testing device can be controlled and adjusted through corresponding operations on the display device;

[0031] The lithium-ion battery separator produced by the separator production line is a PE separator, a ...

Embodiment 2

[0035] Taking the production of PE separators for lithium-ion batteries as an example, the method for real-time monitoring of the thermal shrinkage rate of the separator in the online real-time monitoring system for the thermal shrinkage rate of lithium-ion battery separators in Example 1 is adopted, and the specific process is as follows.

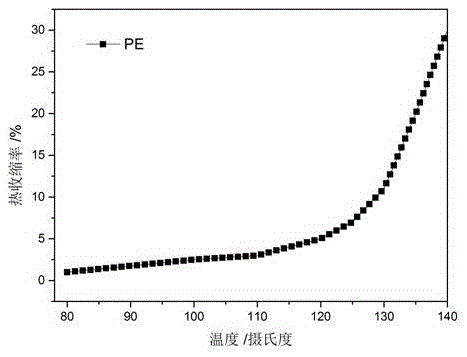

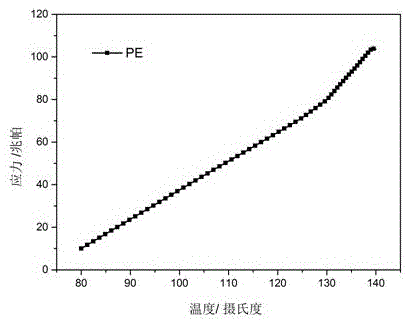

[0036] (1) First, according to the type of lithium-ion electronic separator to be produced, TMA (thermomechanical analysis) test is performed on the finished lithium-ion battery separator (PE separator used in this example) to obtain the corresponding relationship between the thermal shrinkage rate and temperature of the separator .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com