Method and measuring apparatus for determining specific quantities for gas quality

一种测量装置、质量流量的技术,应用在测量装置、比重测量、燃油测试等方向,能够解决不精确实施等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

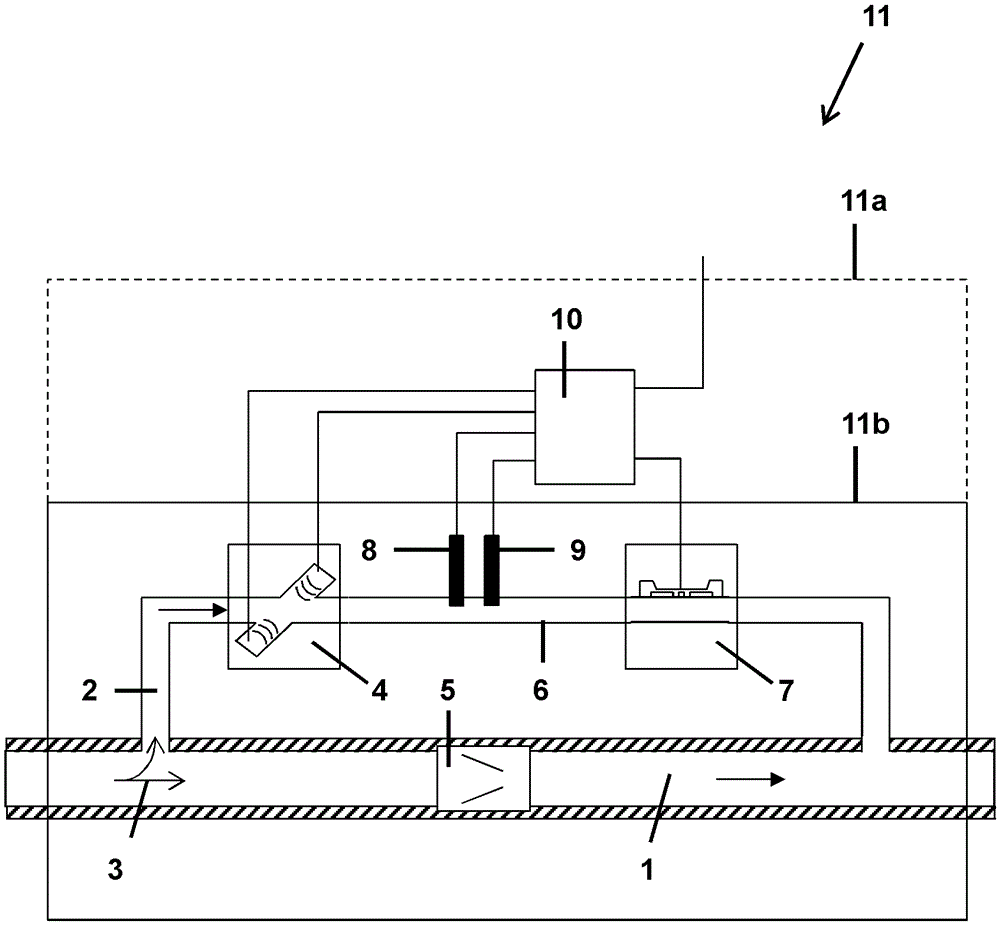

[0128] Figure 1a One embodiment of a microthermal sensor 7 for the measuring device of the invention is shown. Such as Figure 1a As shown in , the microthermal sensor can be an integrated microthermal CMOS hot wire anemometer, which is placed in operation in a bypass gas line and supplied with gas or gas mixture flow 2a. The microthermal CMOS hot wire anemometer comprises a substrate 13 which typically contains a membrane 14 a few micrometers thick. The CMOS hot wire anemometer further comprises two thermocouples 15.1, 15.2 and a heating element 16 which can be arranged between these two thermocouples in the flow direction. The temperature can be detected by means of thermocouples 15.1, 15.2, which are obtained due to the heat exchange 15.1a, 15.2a with the gas or gas mixture flow 2a.

[0129] For further details on the functionality of the integrated microthermal CMOS hot wire anemometer, refer to D. Matter, B. Kramer, T. Kleiner, B. Sabbattini, T. Suter, "Mikroelektroni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com