Lightning protection photoelectric composite cable, grounding layer, armoured layer and manufacturing methods for grounding layer and armoured layer

一种光电复合缆、防雷击的技术,应用在电缆/导体制造、绝缘电缆、缆等方向,能够解决绝缘线芯难分离、加大电缆维护成本、生产速度慢等问题,达到保证导电能力、雷击烧断降低、维护方便的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

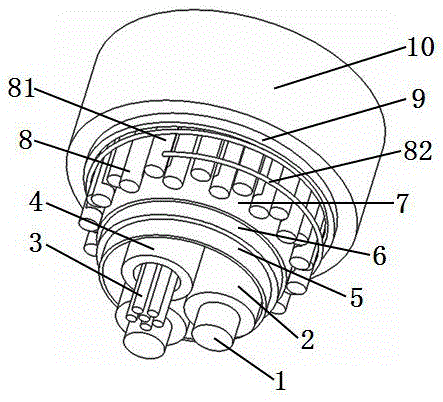

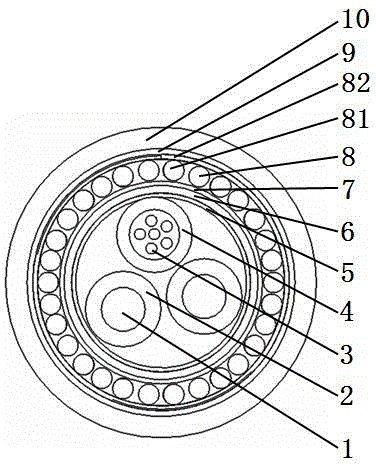

[0057] please see figure 1 and figure 2 , lightning protection photoelectric composite cable, including cable core, inner sheath 6, armor layer 9, outer sheath 10, grounding layer, the cable core is composed of optical unit and electrical unit, the optical unit is made of loose tube 4 and a plurality of optical fibers 3 located in the loose tube, the electrical unit is composed of a conductor 1 and an insulating layer 2 covering the conductor; the cable core is covered with a first protective layer 5, and the inner sheath is extruded and coated Outside the first protective layer, the inner sheath is coated with a second protective layer 7, the grounding layer is located outside the second protective layer, the armored layer is coated outside the grounding layer, and the outer sheath is extruded and coated on the armored layer. In addition to the armor layer; the armor layer is a single-sided coated steel tape, and the surface of the armor layer in contact with the ground lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com