Zinc oxide-based sintered compact, zinc oxide-based sputtering target consisting of this sintered compact, and zinc oxide-based thin film obtained by sputtering this target

A zinc oxide-based, sintered body technology, applied in the direction of sputtering coating, vacuum evaporation coating, ion implantation coating, etc., can solve the problems of easy cracking, low thermal conductivity, unsuitable for high-speed recording, etc., and achieve high thermal efficiency. Effect of permeability and high thermal permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

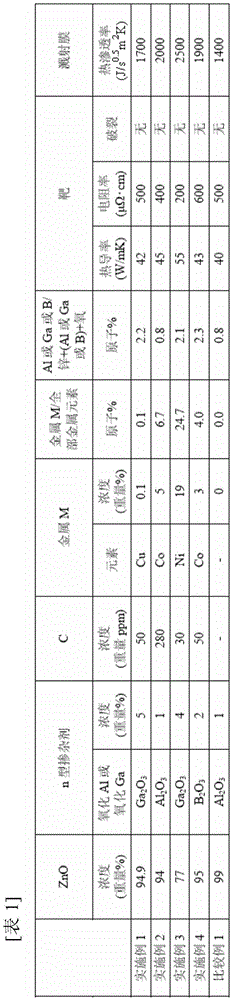

Embodiment 1

[0057] Weigh zinc oxide, gallium oxide (Ga 2 o 3 ) and each raw material powder of Cu (average particle diameter 10 μm) as metal M added to make it 94.9:5.0:0.1 (weight %), and then add carbon powder with an average particle diameter 1 μm so that it becomes 150 weight ppm relative to the total amount, and mixed with a dry ball mill for about 10 hours.

[0058] Next, 1000 g of the mixed raw material components were filled in a mold with a diameter of 170 mm, and the temperature was raised from room temperature at 5° C. / min while blowing argon (Ar) gas. Pressurize to 300kgf / cm in minutes 2 .

[0059] Then, 1000°C, pressure 300kgf / cm 2 The state is maintained for 2 hours, then the heating of the furnace is stopped, and the pressure is reduced to 300kgf / cm in 30 minutes 2 ~0kgf / cm 2 . The target taken out from the furnace was processed into a disc shape with a diameter of 152 mm and a thickness of 5 mm to obtain a sputtering target.

[0060] The produced target did not hav...

Embodiment 2

[0064] Weigh zinc oxide, aluminum oxide (Al 2 o 3 ) and each raw material powder of Co (average particle diameter 10 μm) as metal M added to make it 94:1:5 (weight %), and carbon powder with an average particle diameter 1 μm was added so that it was 500 wtppm relative to the total amount, and mixed with a dry ball mill for about 10 hours.

[0065] Next, 1000 g of the mixed raw material components were filled in a mold with a diameter of 170 mm, and the temperature was raised from room temperature at 5° C. / min while blowing argon (Ar) gas. Pressurize to 300kgf / cm in minutes 2 .

[0066] Then, 1000°C, pressure 300kgf / cm 2 The state is maintained for 2 hours, then the heating of the furnace is stopped, and the pressure is reduced to 300kgf / cm in 30 minutes 2 ~0kgf / cm 2 . The target taken out from the furnace was processed into a disc shape with a diameter of 152 mm and a thickness of 5 mm to obtain a sputtering target.

[0067] The produced target did not have problems su...

Embodiment 3

[0071] Weigh zinc oxide, gallium oxide (Ga 2 o 3 ) and each raw material powder of Ni (average particle diameter 10 μm) as metal M added to make it 77:4:19 (weight %), and carbon powder with an average particle diameter 1 μm was added so that it was 100 weight ppm relative to the total amount, and mixed with a dry ball mill for about 10 hours.

[0072] Next, 1000 g of the mixed raw material components were filled in a mold with a diameter of 170 mm, and the temperature was raised from room temperature at 5° C. / min while blowing argon (Ar) gas. Pressurize to 300kgf / cm in minutes 2 .

[0073] Then, 1000°C, pressure 300kgf / cm 2The state is maintained for 2 hours, then the heating of the furnace is stopped, and the pressure is reduced to 300kgf / cm in 30 minutes 2 ~0kgf / cm 2 . The target taken out from the furnace was processed into a disc shape with a diameter of 152 mm and a thickness of 5 mm to obtain a sputtering target.

[0074] The produced target has no problems such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com