Steam food processor

A cooking machine and steam technology, applied in the field of kitchen utensils, can solve the problems of inability to heat food, reduce steam output efficiency, reduce heating efficiency, etc., achieve good effect, shorten the time of steam output, and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

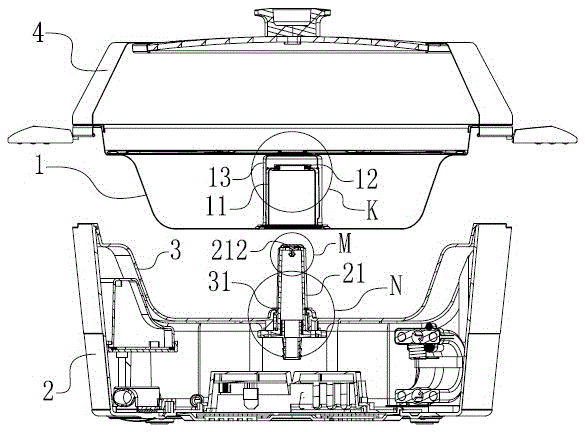

[0033] Such as figure 1 As shown, a steam cooking machine includes a pot body 1, a base 2, a middle ring 3 and a control circuit. The pot body 1 is buckled with a pot cover 4, and the middle ring 3 is covered above the base 2 to close the upper opening of the base 2, and the middle ring 3 is in the shape of a pot matching the bottom of the pot body 1 so that the pot body 1 can be detachably placed on the middle ring 3 .

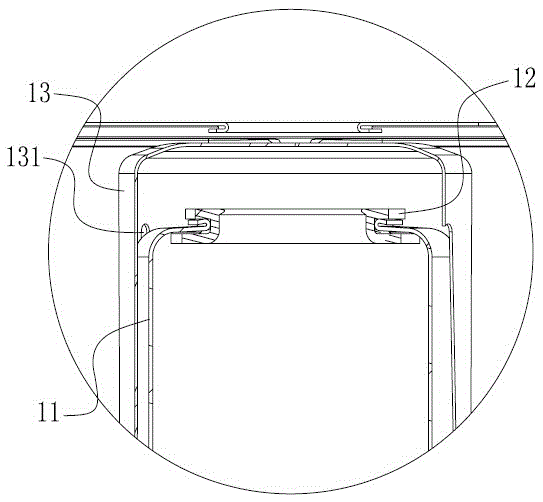

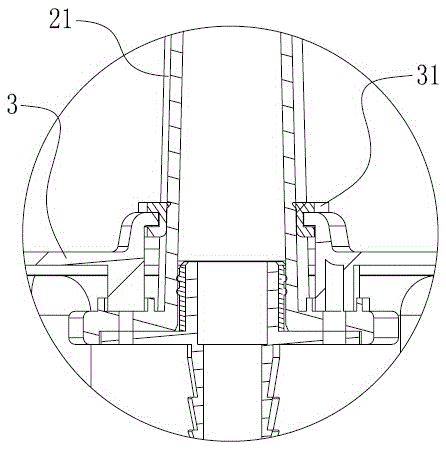

[0034] Such as figure 1 and figure 2 As shown, the center of the bottom of the pot body 1 is provided with a round hole, and the round hole is sealed and connected with a cylindrical isolation cover 11, and the isolation cover 11 is located above the bottom of the pot body 1, that is, the center of the bottom of the pot body 1 is in a convex shape. The upper end surface of the isolation cover 11 is also provided with a circular hole, the circular hole on the upper end surface of the isolation cover 11 is sleeved with a first sealing ring 12, the outer side...

Embodiment 2

[0051] Such as Figure 10 and Figure 11As shown, the difference between this embodiment and Embodiment 1 is that two vertical partitions 2416 are arranged in the box body 241 of the water vapor separation box 24 to divide the space in the box body 241 into a hot water chamber 2417, Integrated chamber 2418 and cold water chamber 2419.

[0052] The top of the hot water chamber 2417 is flush with the tops of the cold water chamber 2419 and the integrated chamber 2418. The lower parts of the two partitions 2416 are respectively provided with small holes, so that the cold water chamber 2419 and the integrated chamber 2418 are communicated through the small holes, and the integrated chamber 2418 and the hot water chamber 2417 are also communicated through the small holes.

[0053] The water inlet 2411 of the water vapor separation box 24 is located at the side of the cold water cavity 2419 .

[0054] The steam outlet 2413 of the steam separation box 24 is located on the upper si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com