Quick coagulation furnace for producing permanent magnet materials

A permanent magnet and quick-setting technology, which is applied in the field of quick-setting furnaces, can solve the problems of slow cooling rate, sheet bonding, large grain size, etc., and achieve uniform cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

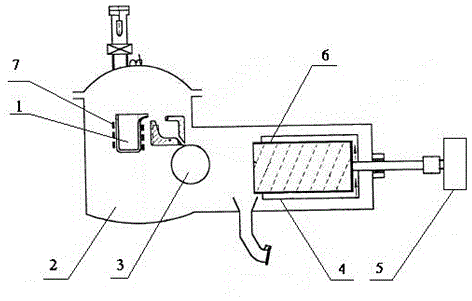

[0011] A quick-setting furnace for producing permanent magnet materials, comprising a furnace body 2, an induction heater 7, a cooling pipe sleeve 4, a crucible 1, a runner 3 and a cylinder 6, and the induction heater 7, the crucible 1 and the runner 3 are all Installed in the furnace body 2 , the cooling pipe sleeve 4 is set on the drum 6 , and the drum 6 is arranged on the side of the rotating wheel 3 .

[0012] In the present invention, the drum 6 is connected with the transmission device 5 .

[0013] Above shows and described basic principle of the present invention and main feature and the advantage of the present invention, those skilled in the art should understand that, the present invention is not limited by above-mentioned embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com