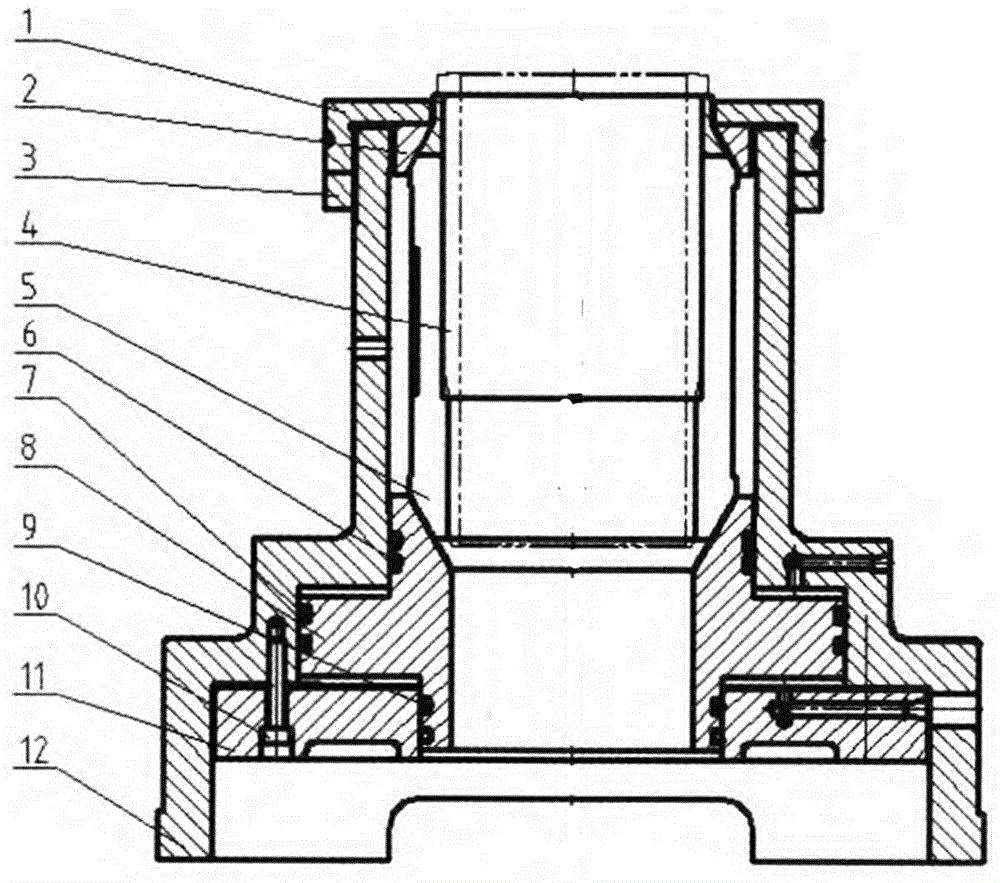

Fine boring fixture in cylinder jacket machining

A machining and cylinder liner technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problem of increasing auxiliary time and labor intensity of workers, poor coaxiality between the inner circle and the upper and lower belts of the cylinder liner, and the problem of cylinder liner. The problem of poor roundness in the fine boring of sets can shorten auxiliary man-hours and reduce the labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The cylinder liner machining fine boring jig of the present invention includes a clamp body 12, the inner cavity of the clamp body 12 is three-step shape, the middle inner cavity is an oil cylinder, and a hollow piston 8 is installed in the oil cylinder, and the upper part of the inner hole of the piston 8 is Conical surface, and the outer circle of the piston 8 is provided with a middle sealing groove 7, the upper outer circle of the piston 8 matches the lower part of the upper cavity wall of the clamp body 12, and the upper outer circle of the piston 8 is also provided with an upper sealing groove 6, The lower part of the inner cavity of the clamp body 12 is connected with a cylinder head 11 through bolts 10, the outer circle of the lower part of the piston 8 matches the inner circle of the cylinder head 11, and the outer circle of the lower part of the piston 8 is provided with a lower sealing groove 9. Sealing rings are all installed, and an expansion sleeve 5 with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com