Surface treatment shot blasting device for steel structure

A technology of surface treatment and shot blasting equipment, which is applied in the direction of used abrasive treatment equipment, abrasives, metal processing equipment, etc., can solve the problems of heavy workload, low production efficiency, time-consuming and laborious, etc., and achieve reasonable structure and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

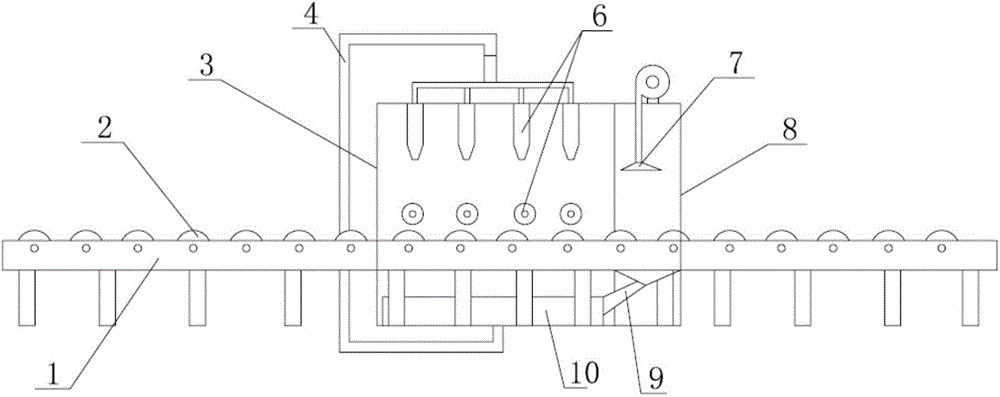

[0025] The welded and assembled steel structure is placed on the conveying platform 1, transported forward by the rolling of the roller shaft 2, and enters the shot blasting and polishing box 3, and the steel shot in the steel shot nozzle 6 is sprayed out, continuously and omnidirectionally hitting the On the surface of the steel structure, the oxide layer on the surface of the steel structure is removed, and the steel structure after shot blasting enters the air blowing cleaning box 8, and the powder or steel shots on the surface are blown off by the blowing of the air blowing pipe 7, and the steel structure The shot rolls down into the steel shot collection box 10 through the collection funnel 9 .

[0026] The steel shot in the shot blasting box 3 and the blowing cleaning box 8 is collected in the steel shot collection box 10 and is continuously transported to each steel shot nozzle 6 through the pipeline 4, so as to realize the repeated utilization of the steel shot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com