Symmetrical parallel mechanism without singularities

A symmetrical and singular technology, applied in the field of symmetrical parallel mechanisms, can solve the problems of difficult mechanism trajectory planning, trajectory planning and control, etc., and achieve the effect of good motion characteristics, simple driving form and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

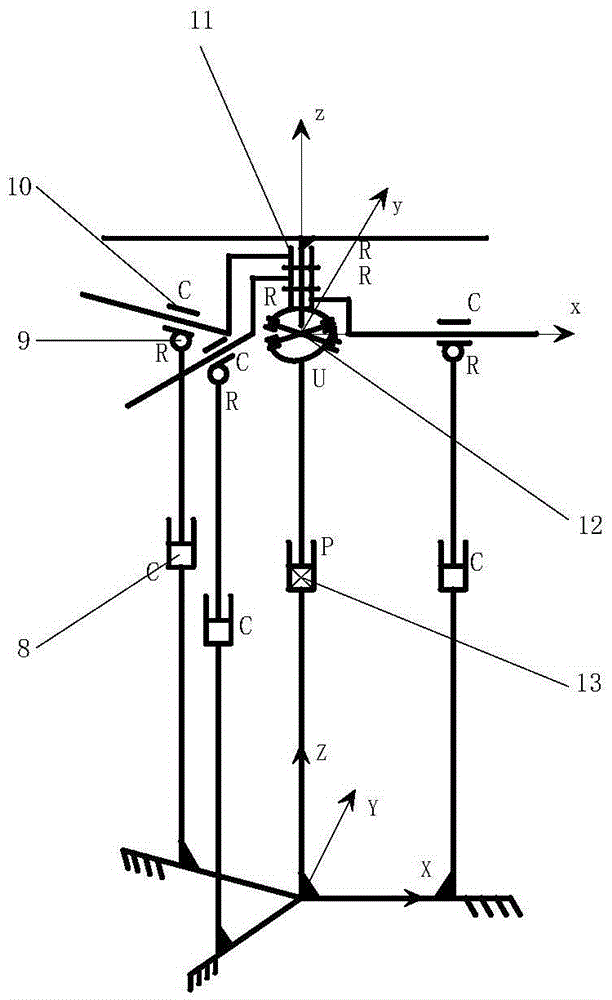

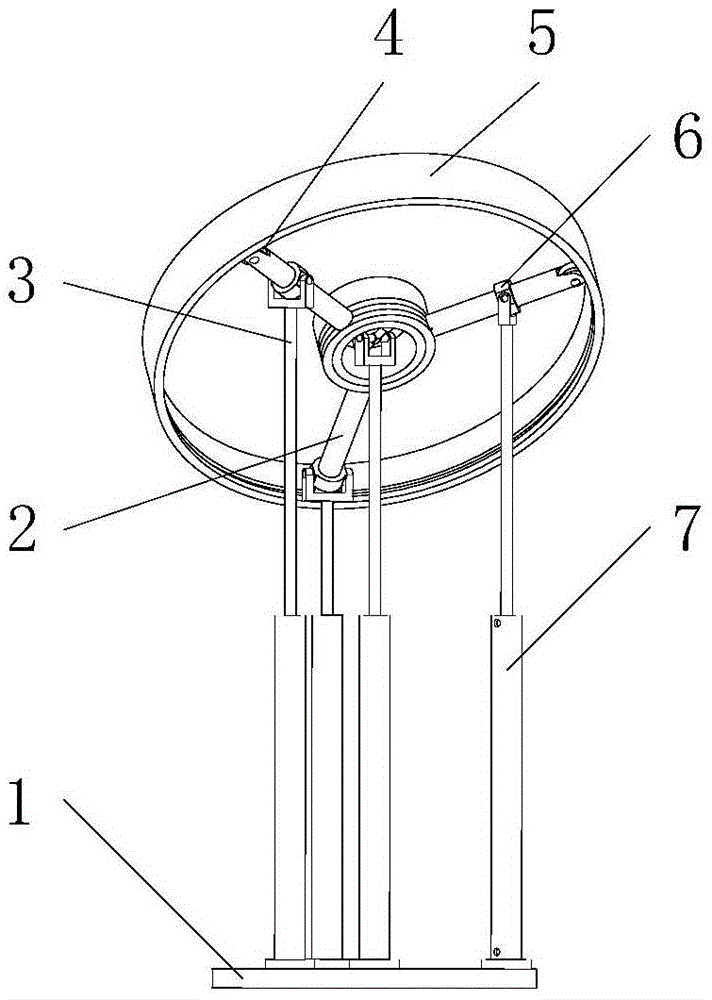

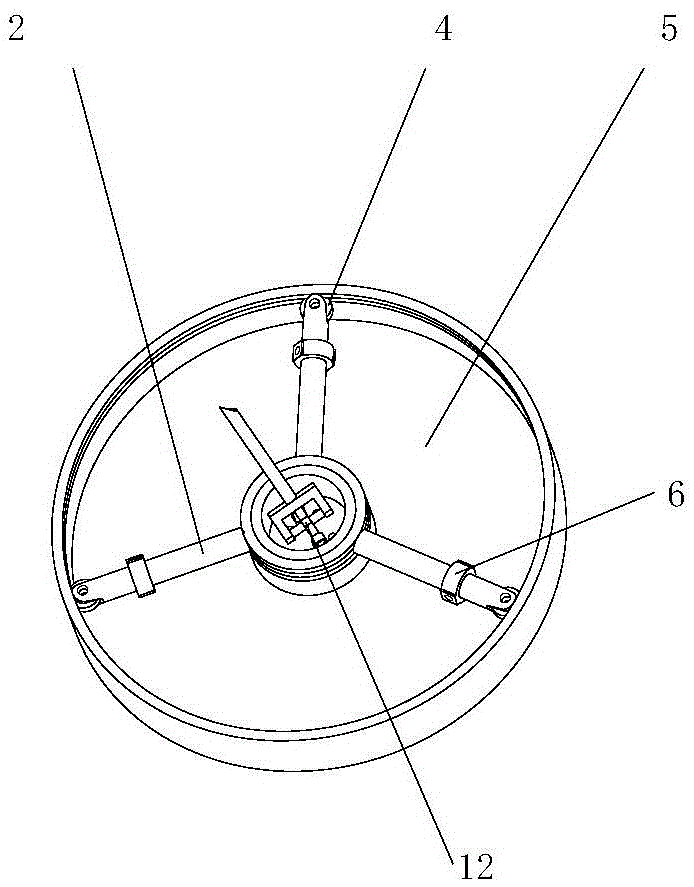

[0019] The present invention is a symmetrical parallel mechanism without singular configuration, such as figure 1 and figure 2 As shown, it includes the moving platform 5, the fixed platform 1 as the frame, and four motion branch chains connecting the moving platform and the fixed platform. And three identical motion branch chains, the three identical motion branch chains include the hydraulic cylinder 7 fixedly connected with the fixed platform 1, the three hydraulic cylinders 7 are respectively connected to the piston rod 3 through the cylinder pair A8, and the three piston rods 3 are respectively Connect with the ring member 6 through the rotating pair A9, such as image 3 As shown, the three annular members 6 are respectively connected to the sliding rod 2 through the cylindrical pair B10, one end of each sliding rod 2 is connected to the center of the moving platform 5 through the rotating pair B11, and the other end of the sliding rod 2 is connected to the roller 4 thr...

Embodiment 2

[0033] The present invention is a symmetrical parallel mechanism without singular configuration, such as figure 2 and Figure 4 As shown, it includes a moving platform 5, a fixed platform 1 as a frame, and four motion branch chains connecting the moving platform 5 and the fixed platform 1. Constraint chain and three identical motion branch chains, the three identical motion branch chains include hydraulic cylinder 7 fixedly connected with fixed platform 1, three hydraulic cylinders 7 and piston rod 3 through cylinder pair A8, and three piston rods 3 are respectively connected with the ring member 6 through the rotating pair A9, such as image 3As shown, the three annular members 6 are respectively connected to the sliding rod 2 through the cylindrical pair B10, one end of each sliding rod 2 is connected to the center of the moving platform 5 through the rotating pair B11, and the other end of the sliding rod 2 is connected to the roller 4 through the rotating pair, The roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com