Production technology of dry-mixed mortar

A technology of dry powder mortar and production process, which is applied in the direction of clay preparation equipment, mixing operation control, mixing plant, etc., can solve the problems of lack of production process, deterioration of resources and environment, etc., and achieve the advantages of convenient use, high mixing ratio and high batching precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

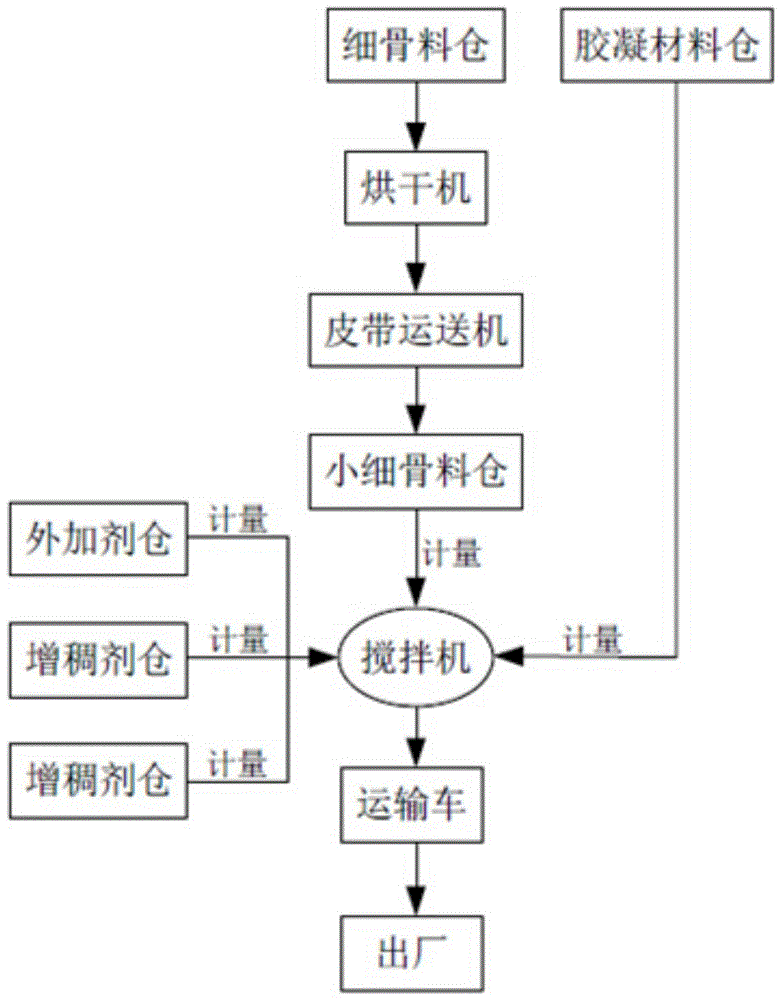

[0014] A production process of dry powder mortar, including material preparation, batching, adding additives, lifting and mixing.

[0015] Material preparation: Add recycled aggregate to the fine aggregate bin, transport the recycled aggregate to the dryer for drying through the lifting mechanism, lift the dry powder to remove dust, and then transport it to the fine aggregate bin through the belt conveyor. Ingredients: Weigh all kinds of dry powder according to the proportion for later use. With additives: weighing according to the proportion, configure thickener, admixture, gelling agent. Elevate: Lift the prepared raw materials to the raw material tank. Mixing: Put the weighed raw materials into the mixer at a lower position to make the mixture evenly mixed. After mixing, it is packaged into bags or bulk trucks or stored in finished product warehouses.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com