Rail transit electric drive hydraulic brake control system

A hydraulic braking and rail transit technology, applied in the braking field of rail transit vehicles, can solve the problems of slow braking response and long braking force establishment time, and achieve precise control of braking force, light weight, and easy fault diagnosis. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

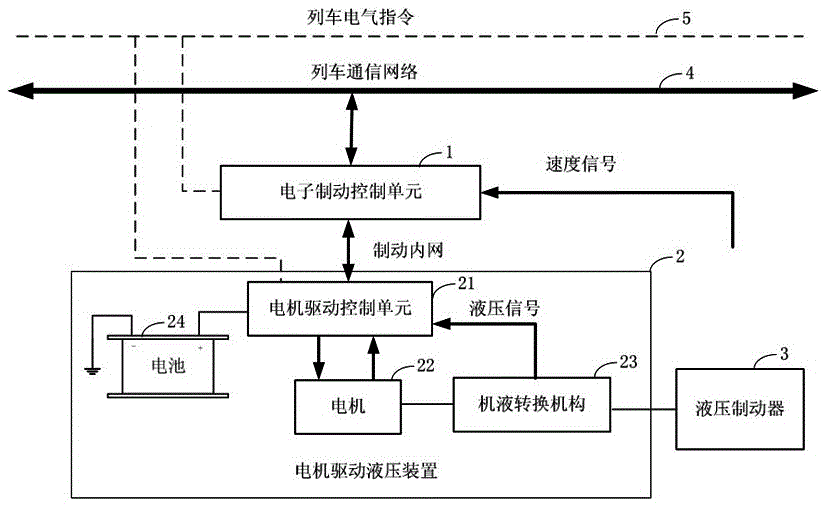

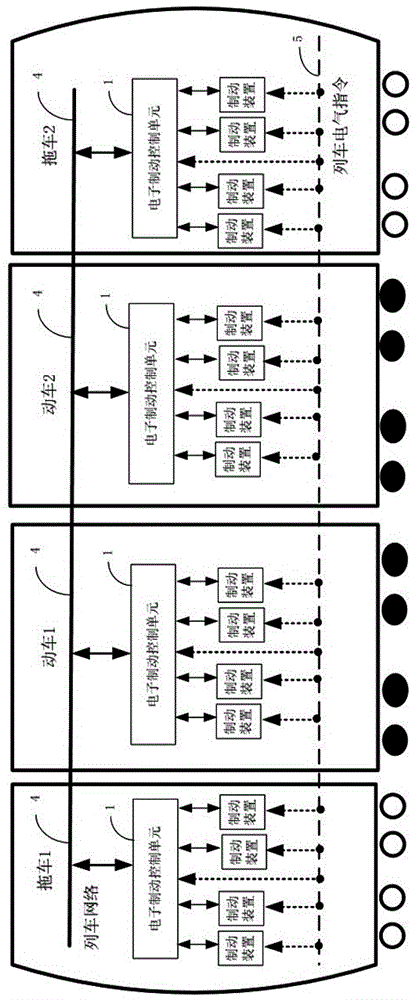

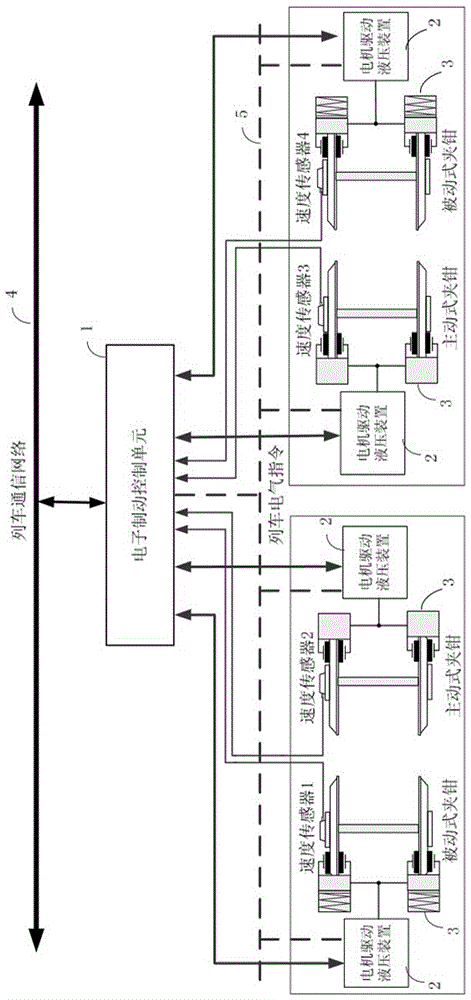

[0020] Such as figure 1 As shown, the rail transit electric drive hydraulic brake control system of the present invention includes an electronic brake control unit 1, a motor-driven hydraulic device 2 and a hydraulic brake 3, and the electronic brake control unit 1 receives the brake command through the train communication network 4 and For braking force distribution and control, the electronic brake control unit 1 performs data interaction with the motor-driven hydraulic device 2 through the brake internal network, and the motor-driven hydraulic device 2 converts the braking force request into a hydraulic signal, and the hydraulic signal drives the hydraulic brake 3 to complete action.

[0021] In this embodiment, the motor-driven hydraulic device 2 includes a motor-driven control unit 21, a motor 22, a mechanical-hydraulic conversi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com