Small airplane fuel supply system

A technology of fuel supply system and small aircraft, applied in aircraft parts, aircraft power units, fuel supply of power units, etc., can solve problems such as affecting system operation stability, fuel suction port hanging in the air, affecting flight safety, etc., to enhance flexibility Compensation capability and fire protection design requirements, the effect of reducing fuel vapor and improving flight safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

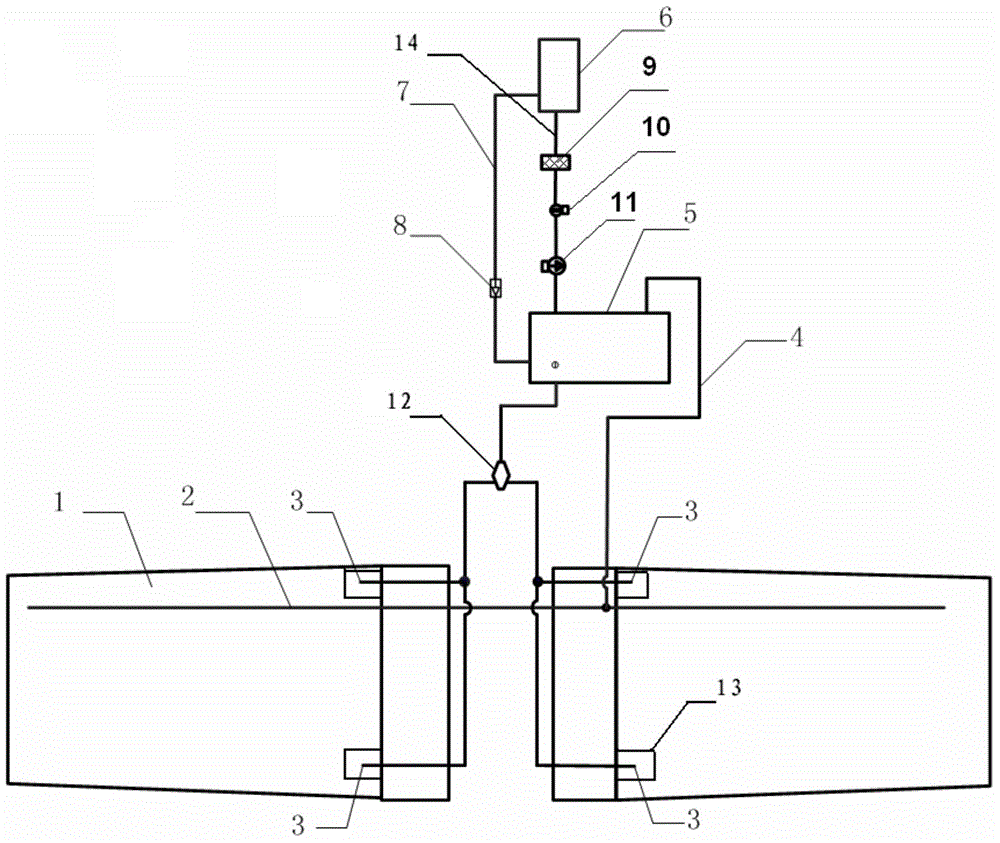

[0006] The specific implementation manner of the present invention will be described in combination with the drawings of the invention. Such as figure 1 , the lower positions of the left and right wing fuel tanks 1 are respectively designed with two fuel inlets 3, and each fuel inlet 3 is designed with an oil sump 13, which can ensure that at least one fuel inlet 3 can suck fuel under various flight attitudes of the aircraft. , to ensure continuous and reliable supply of fuel to the engine; the oil supply pipelines of the left and right wing fuel tanks are aggregated after the fuel selector 12, which can maintain the fuel balance of the left and right wings; the lower position of the fuel supply pipeline is designed with a fuel collection tank 5, which is usually full of fuel state, the upper part is designed with a ventilation pipeline 4, which is connected with the wing fuel tank ventilation pipeline 2, and the gas in the fuel supply pipeline and the oil collection tank 5 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com